roll forming machine for perfil drywall parante companies

Roll Forming Machines for Drywall Profile Manufacturers

In the modern construction landscape, efficiency and quality are paramount. One of the innovative solutions that have emerged to meet these demands is the use of roll forming machines specialized for producing drywall profiles. The drywall industry, instrumental in shaping interiors, relies heavily on precision and rapid production, hence the growing importance of roll forming technologies.

Understanding Roll Forming Machines

Roll forming is a continuous bending operation in which a long strip of metal is passed through consecutive pairs of rolls that progressively shape the metal into the desired cross-section. This process is highly efficient for producing long lengths of parts, making it an ideal choice for the manufacturing of drywall profiles, or parantes as they are referred to in Spanish.

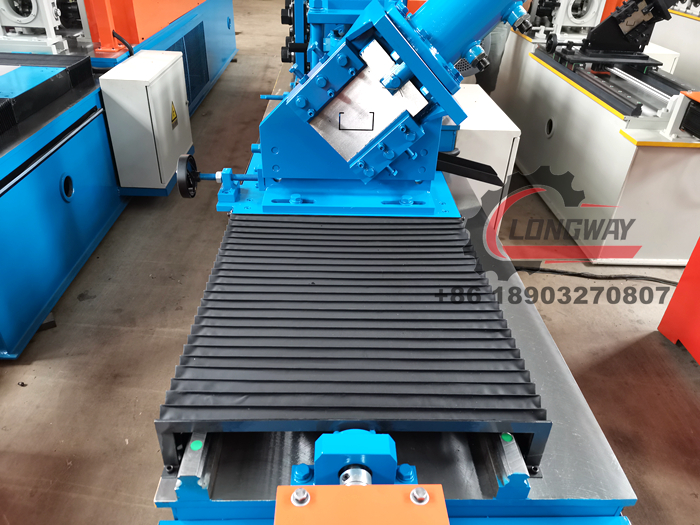

A roll forming machine designed for drywall profiles typically includes several key components a decoiler for unwinding the metal coil, a series of rollers for shaping the material, and a cut-off device for cutting the profiles to the required length. The entire setup is often automated, allowing for significant reductions in labor costs and minimization of human error.

Benefits of Using Roll Forming Machines

1. High Production Speed Roll forming machines can operate at high speeds, allowing manufacturers to produce large volumes of drywall profiles quickly. This is crucial in meeting the demand in construction, where time is often of the essence.

2. Precision and Consistency The automation and design of roll forming processes ensure that each profile produced is uniform in dimensions and quality. This consistency is vital for drywall installation, which requires exact fittings for structural integrity.

3. Material Efficiency Roll forming processes typically produce less scrap compared to other machining methods. The process maximizes material usage, which is not only cost-effective but also environmentally friendly.

roll forming machine for perfil drywall parante companies

4. Design Flexibility Modern roll forming machines can produce a wide range of profile shapes and sizes. This versatility allows manufacturers to cater to various market segments, from residential building to commercial infrastructure.

5. Reduced Labor Costs Automated machines require less manual intervention, allowing companies to reduce labor costs. This efficiency also means that workers can focus on more complex tasks, enhancing overall productivity.

6. Durability of Products Steel profiles produced via roll forming are known for their strength and durability, making them ideal for drywall constructions that need to withstand various environmental stresses.

Market Trends and Future Outlook

The drywall sector is poised for growth, driven by rising construction activities globally. As urbanization increases and housing demand grows, the need for efficient drywall solutions will continue to rise. Consequently, investment in advanced roll forming machines will be crucial for manufacturers looking to expand their production capabilities and maintain competitive advantages.

Moreover, the integration of smart technologies, such as IoT sensors and automation, into roll forming machines stands to revolutionize production processes. These technologies can provide real-time data analysis, which enables predictive maintenance, enhanced quality control, and optimized workflow management. Companies that adopt these advancements will improve operational efficiencies and adapt more swiftly to market demands.

Conclusion

As the construction industry evolves, the significance of roll forming machines for producing drywall profiles cannot be overstated. These machines not only enhance production capabilities but also ensure quality and efficiency – indispensable elements in today’s fast-paced market. For manufacturers of drywall profiles, investing in advanced roll forming technology stands as a strategic move towards sustainability and growth.

In conclusion, the future of drywall production is likely to see even more integration of technology, making the role of roll forming machines increasingly critical. Their ability to produce high-quality, durable products quickly and efficiently will solidify their place in the manufacturing landscape of drywall profiles. This trend not only benefits manufacturers but also contributes to the broader construction industry by meeting the ongoing demand for superior building materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025