Custom Aluminum Roll Forming Equipment for Precision Manufacturing Solutions

Exploring the Advantages of Custom Aluminum Roll Forming Machines

In the world of metal fabrication, efficiency and precision are paramount. One of the most innovative solutions to achieve these qualities is the custom aluminum roll forming machine. This specialized equipment works by continuously bending a strip of metal, commonly aluminum, into desired shapes through a series of rollers. As industries evolve and demands increase, the benefits of utilizing custom aluminum roll forming machines are becoming increasingly apparent.

The Basics of Roll Forming

Roll forming is a process that allows manufacturers to create complex shapes with exceptional consistency and accuracy. The machine feeds a flat aluminum sheet or coil into a series of rollers arranged in a specific sequence. Each roller gradually bends the material, yielding the final shape. What sets custom machines apart is their ability to cater to specific design requirements—this adaptability is crucial in today’s market where customization is treasured.

Advantages of Customization

1. Tailored Solutions One of the most significant advantages of custom aluminum roll forming machines is their ability to produce tailored profiles. Whether it’s for construction, automotive, or electronics, different applications require distinct shapes. A custom machine can be designed to produce a specific profile that meets the unique demands of a project, enhancing product functionality and aesthetic appeal.

2. Enhanced Efficiency Custom machinery is built with specific production goals in mind, improving efficiency. By optimizing the roll forming process for a particular type of aluminum profile, these machines can operate at higher speeds without compromising quality. This not only accelerates production time but also reduces operational costs.

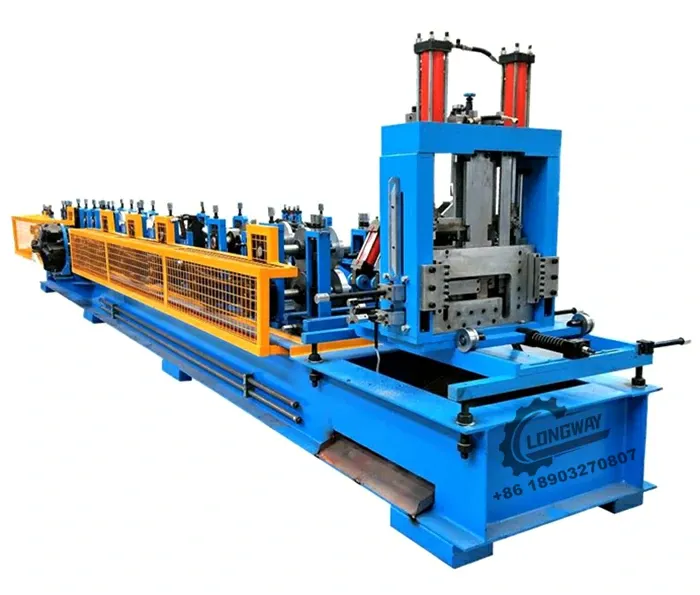

custom aluminum roll forming machine

3. Material Utilization Roll forming is an efficient process that minimizes waste. Since the machine can produce the exact dimensions required, there is less scrap material generated compared to other manufacturing methods. Additionally, custom machines can often run with a variety of aluminum grades, allowing for greater flexibility in sourcing materials.

4. Increased Strength and Durability The roll forming process enhances the structural integrity of aluminum products. Custom machines can optimize the wall thickness and shape design, ensuring that the final product possesses the necessary strength and durability required for its application.

5. Consistency and Precision Precision is vital in manufacturing, especially in industries like aerospace and automotive, where safety and reliability are critical. Custom aluminum roll forming machines offer consistency in production. Each unit produced adheres to strict dimensional tolerances, which is essential for components that must fit seamlessly together.

6. Reduced Labor Costs With automated systems that custom roll forming machines utilize, the need for manual labor is significantly reduced. Automation leads to fewer manpower requirements, which translates into lowered labor costs. This is especially beneficial in high-volume manufacturing environments where maintaining profit margins is crucial.

Future Prospects

As technologies continue to advance, the capabilities of custom aluminum roll forming machines are expected to evolve. Innovations in automation, monitoring systems, and artificial intelligence will further enhance the precision and efficiency of the roll forming process. Industries will inevitably benefit from lower costs and improved production times, leading to an even broader adoption of these machines.

In conclusion, custom aluminum roll forming machines offer a plethora of advantages, making them invaluable in various industries. From tailored design solutions and improved material utilization to enhanced strength and reduced production costs, the benefits of this innovative technology highlight the necessity for manufacturers to consider incorporating custom roll forming into their production lines. As the demand for precision and efficiency grows, so too will the importance of these specialized machines in the realm of metal fabrication.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025