Company for Manufacturing Corrugated Metal Sheets Using Advanced Machinery

The Evolution of Machines in Corrugated Metal Sheet Production

The construction industry relies heavily on various materials, and one of the most essential components is corrugated metal sheets. These sheets are known for their strength, durability, and versatility, making them a popular choice for roofing, siding, and various industrial applications. The process of manufacturing these sheets has evolved significantly over the years, largely due to advancements in technology and machinery. In this article, we will explore the machines that make corrugated metal sheets, the benefits they offer, and the future of this industry.

The Manufacturing Process

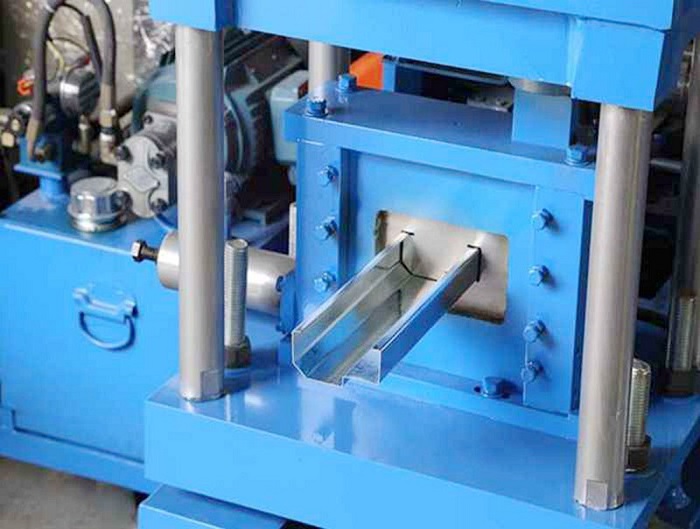

The production of corrugated metal sheets begins with raw materials, usually steel or aluminum. These materials are first shaped into flat sheets before they undergo the corrugating process. The key machine in this production line is the corrugating machine, which uses rollers to imprint a wave-like pattern onto the metal sheets. This corrugated design provides increased structural strength, allowing the sheets to withstand various environmental conditions, such as wind, rain, and snow.

Modern corrugating machines are highly sophisticated, equipped with advanced technology to enhance efficiency and precision. Many machines now include computerized controls, which allow operators to easily adjust settings for different sheet sizes and styles. This flexibility is crucial for manufacturers to meet the diverse needs of their clients, from small custom orders to large-scale production runs.

Benefits of Advanced Machining

The introduction of automated and high-speed machinery in the corrugated metal sheet production process has brought numerous benefits. Firstly, these machines significantly increase production rates, allowing manufacturers to meet the growing demand for corrugated sheets in various sectors, including construction, agriculture, and transportation. Faster production times result in lower labor costs and increased profitability for businesses.

machine to make corrugated metal sheet company

Additionally, advanced technology has improved the quality of the output. Machines today can produce corrugated sheets with precise dimensions and consistent quality, minimizing waste and reducing the likelihood of defects. This is vital for maintaining a good reputation in the market, as customers expect reliable and durable materials.

Environmental sustainability is another consideration that modern machines address. Many manufacturers have started adopting eco-friendly practices, such as recycling scrap metal generated during the production process. Additionally, energy-efficient machines reduce the carbon footprint of manufacturing operations, aligning with global efforts to promote sustainability.

The Future of Corrugated Metal Sheet Production

As technology continues to advance, the future of corrugated metal sheet production looks promising. The integration of artificial intelligence (AI) and the Internet of Things (IoT) into manufacturing processes will further transform the industry. Smart machines that can monitor performance, predict maintenance needs, and optimize production lines are on the horizon, leading to an even more efficient and cost-effective manufacturing process.

Furthermore, the growing trend towards customization presents exciting opportunities for manufacturers. With machines capable of producing bespoke designs and sizes, companies can cater to niche markets and unique projects, opening new avenues for growth.

In conclusion, the evolution of machines for producing corrugated metal sheets has revolutionized the manufacturing process. With the advent of advanced technology, manufacturers benefit from increased efficiency, improved quality, and sustainable practices. As the industry continues to evolve, the use of cutting-edge machinery will play a crucial role in shaping the future of corrugated metal sheet production, ensuring that it meets the demands of modern society while maintaining high standards of quality and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025