custom portable standing seam roll former

The Evolution of Custom Portable Standing Seam Roll Formers

In the realm of modern construction and roofing systems, the importance of efficiency and versatility has never been more paramount. Enter the custom portable standing seam roll former – a revolutionary tool designed to streamline the production of high-quality standing seam metal roofing panels on-site. This article delves into the significance, benefits, and applications of this innovative equipment.

What is a Standing Seam Roof?

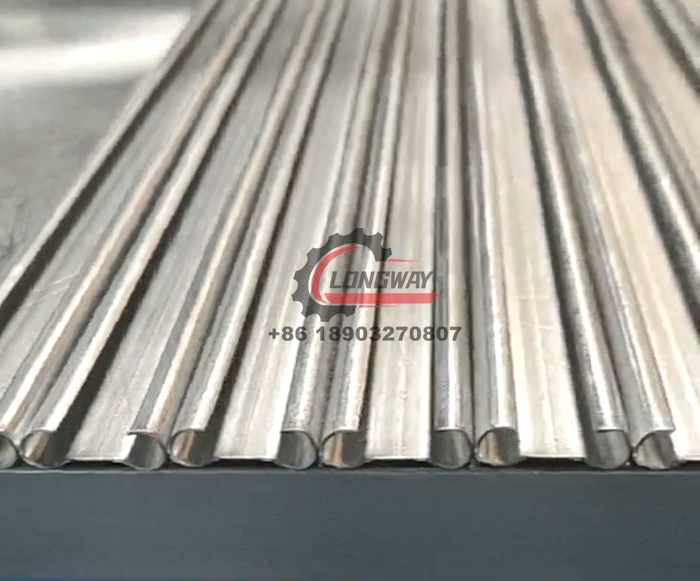

Standing seam roofs are characterized by raised seams that run vertically along the slope of the roof. These seams interlock, creating a weather-resistant barrier that protects against leaks and weather damage. Such roofs are often made from durable metal materials like aluminum or steel, offering longevity and aesthetic appeal. The ability to customize metal panels on-site using a portable roll former can significantly enhance the installation process.

The Advantages of Portable Roll Formers

The advent of portable standing seam roll formers marks a pivotal shift in how contractors approach metal roofing projects. Traditionally, roofs were constructed using pre-made panels shipped from manufacturers, which often led to challenges such as transportation costs, delays, and material waste. Portable roll formers tackle these issues effectively.

1. On-Site Production One of the primary benefits of custom portable standing seam roll formers is the ability to create metal panels on-site. This eliminates the need for transporting voluminous panels from the factory, thereby reducing costs and the risk of damage during transit. Contractors can produce panels that fit the exact dimensions of the roofing project, ensuring a better fit and finish.

2. Customization With a portable roll former, contractors can easily customize panel length, width, and profile according to the specific requirements of each project. This flexibility allows for creative design options and accommodates various architectural styles, making it an attractive option for residential and commercial buildings alike.

custom portable standing seam roll former

3. Efficient Production The efficiency of a portable standing seam roll former means that roofing projects can be completed in significantly less time. By producing panels as needed, contractors can minimize downtime and maximize productivity. This efficiency is crucial in meeting tight project deadlines and enhances overall profitability.

4. Reduced Waste Because panels are manufactured to fit the specific dimensions of a roof, there is significantly less material waste compared to using pre-formed panels. This not only saves money but also aligns with sustainable building practices, an increasingly important factor in the construction industry.

5. Ease of Use Modern portable roll formers are designed with user-friendly features, allowing contractors to operate them with minimal training. The mobility of these machines further enhances their usability, as they can be easily transported to various job sites, making them an invaluable asset for any roofing contractor.

Applications in the Construction Industry

Custom portable standing seam roll formers have wide-ranging applications beyond traditional roofing. They are also beneficial in creating wall panels, fascia, and other architectural elements that require a sleek, modern finish. The versatility of these machines makes them an indispensable tool in residential, commercial, and industrial projects.

Moreover, the rising trend towards sustainable construction practices has propelled the demand for metal roofing systems. This increase is driven by the longevity, recyclability, and energy efficiency that metal roofs provide, further validating the need for adaptable solutions like portable roll formers.

Conclusion

The custom portable standing seam roll former represents a significant advancement in the construction industry, blending technology with practicality to meet modern demands. By enabling on-site customization, efficiency, and sustainability, this innovative tool empowers contractors to deliver high-quality roofing solutions that meet the diverse needs of their clients. As the industry continues to evolve, investing in such technology will be crucial for those looking to stay competitive in an ever-changing market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025