Feb . 12, 2025 16:49

Back to list

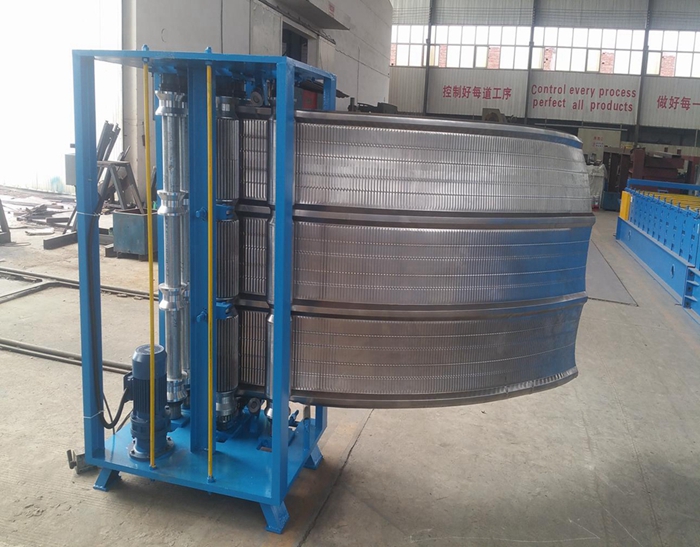

c shaped channel roll forming machine

Investing in a C-shaped channel roll forming machine is a significant move that can revolutionize manufacturing processes, offering precision, efficiency, and cost-effectiveness. Businesses ranging from small-scale manufacturers to large industrial firms can benefit from the numerous advantages that these machines offer. Here is an in-depth exploration that examines the critical components, operational benefits, and competitive edges provided by C-shaped channel roll forming machines.

Energy efficiency and reduced labor costs further contribute to the machine's appeal. Once set, the roll forming process is automated, requiring minimal operator intervention and thus lowering labor costs and reducing human error. Additionally, the latest models are equipped with energy-efficient components, aligning with the growing demand for environmentally sustainable manufacturing solutions. Investing in a C-shaped channel roll forming machine is also a strategy for businesses seeking to enhance their reputation for reliability and quality. The precision and consistency of products manufactured using these machines translate into end-products that are durable and reliable. This quality assurance fosters trust among clients and partners, enhancing brand reputation and market positioning. Safety and ease of use are additional highlights of modern roll forming machines. With integrated safety features, these machines prioritize operator safety while offering user-friendly interfaces that simplify operation and maintenance. This ensures not only reduced downtime but also extends the lifespan of the machine itself, providing long-term operational benefits and maximizing return on investment. Moreover, the adoption of a C-shaped channel roll forming machine can significantly enhance a company's ability to respond swiftly to market demands. With increased production capacity and flexibility, manufacturers can adapt to rapid changes in consumer preferences and industry standards, securing a steadier market presence and ensuring long-term business sustainability. In summary, a C-shaped channel roll forming machine is not just an addition to a company's production line; it is a transformative asset that combines technology, efficiency, and reliability. From small-batch producers to large-scale industrial manufacturers, the versatility, consistency, and cost-efficiency of these machines offer undeniable benefits that can redefine manufacturing processes and propel business growth. As industries continue to evolve, the role of innovative equipment like the C-shaped channel roll forming machine will undoubtedly become more integral to maintaining competitiveness and operational excellence in a global market.

Energy efficiency and reduced labor costs further contribute to the machine's appeal. Once set, the roll forming process is automated, requiring minimal operator intervention and thus lowering labor costs and reducing human error. Additionally, the latest models are equipped with energy-efficient components, aligning with the growing demand for environmentally sustainable manufacturing solutions. Investing in a C-shaped channel roll forming machine is also a strategy for businesses seeking to enhance their reputation for reliability and quality. The precision and consistency of products manufactured using these machines translate into end-products that are durable and reliable. This quality assurance fosters trust among clients and partners, enhancing brand reputation and market positioning. Safety and ease of use are additional highlights of modern roll forming machines. With integrated safety features, these machines prioritize operator safety while offering user-friendly interfaces that simplify operation and maintenance. This ensures not only reduced downtime but also extends the lifespan of the machine itself, providing long-term operational benefits and maximizing return on investment. Moreover, the adoption of a C-shaped channel roll forming machine can significantly enhance a company's ability to respond swiftly to market demands. With increased production capacity and flexibility, manufacturers can adapt to rapid changes in consumer preferences and industry standards, securing a steadier market presence and ensuring long-term business sustainability. In summary, a C-shaped channel roll forming machine is not just an addition to a company's production line; it is a transformative asset that combines technology, efficiency, and reliability. From small-batch producers to large-scale industrial manufacturers, the versatility, consistency, and cost-efficiency of these machines offer undeniable benefits that can redefine manufacturing processes and propel business growth. As industries continue to evolve, the role of innovative equipment like the C-shaped channel roll forming machine will undoubtedly become more integral to maintaining competitiveness and operational excellence in a global market.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products