Feb . 12, 2025 17:18

Back to list

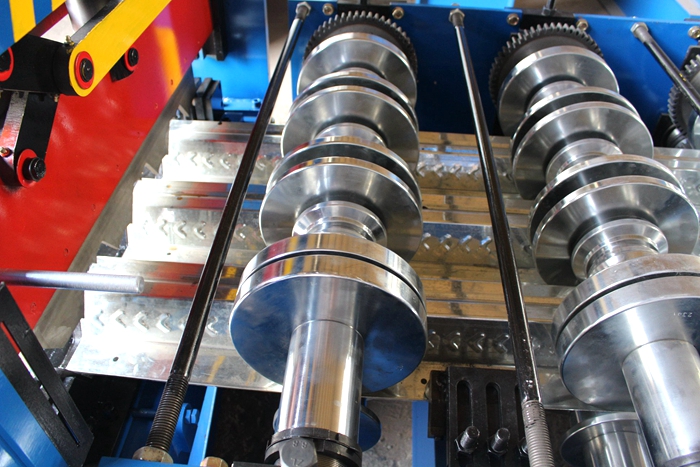

c to z purlin roll forming machine

The evolution of construction technology has been remarkable, and at the heart of this transformation is the efficient and versatile C to Z purlin roll forming machine. A cornerstone for modern construction projects, these machines enable the production of high-quality metal purlins used predominantly in building structures, roofing, and wall applications. Understanding the nuances of these machines is crucial for construction professionals looking to enhance structural integrity and efficiency.

Moreover, trustworthiness, an essential factor in the construction industry, is inherent in the performance of the C to Z purlin roll forming machine. Companies investing in such technology are assured of its pedigree and the superior technology backing it. These machines are often constructed using premium-grade materials and engineered through processes that align with global manufacturing standards. Such integrity in design and functionality builds trust among users who rely on it for stable and uninterrupted operation over prolonged periods. From a practical experience perspective, operators and construction managers consistently report on substantial increases in efficiency and reductions in waste. The fine-tuning available within the system ensures minimal raw material wastage, and the robust construction of the machine promises durability and longevity, minimizing downtime and maintenance costs. As a result, these machines not only prove to be cost-effective but also environmentally friendly, supporting sustainable construction initiatives. Incorporating a C to Z purlin roll forming machine into your construction arsenal can elevate your project's profile significantly. Through precision engineering, advanced technology, and reliability, it embodies the core principles of modern construction methodology. Whether for small scale or vast construction ventures, the adoption of this technology is a testament to commitment towards quality, efficiency, and sustainability. Choosing the right C to Z purlin roll forming machine requires understanding the specific requirements of your projects. Manufacturers offer machines with varied capabilities in terms of speed, output size, and automation level. Engaging with the right supplier ensures that you access comprehensive support, from installation to operational training, underlying the importance of partnership in achieving optimal outcomes. The C to Z purlin roll forming machine represents a significant leap in technological advancement for the construction industry. Through its enormous value addition, it not only simplifies complex construction processes but significantly enhances the quality of output. Its continued evolution and integration into construction projects worldwide underscore its central role in advancing modern architectural design and implementation.

Moreover, trustworthiness, an essential factor in the construction industry, is inherent in the performance of the C to Z purlin roll forming machine. Companies investing in such technology are assured of its pedigree and the superior technology backing it. These machines are often constructed using premium-grade materials and engineered through processes that align with global manufacturing standards. Such integrity in design and functionality builds trust among users who rely on it for stable and uninterrupted operation over prolonged periods. From a practical experience perspective, operators and construction managers consistently report on substantial increases in efficiency and reductions in waste. The fine-tuning available within the system ensures minimal raw material wastage, and the robust construction of the machine promises durability and longevity, minimizing downtime and maintenance costs. As a result, these machines not only prove to be cost-effective but also environmentally friendly, supporting sustainable construction initiatives. Incorporating a C to Z purlin roll forming machine into your construction arsenal can elevate your project's profile significantly. Through precision engineering, advanced technology, and reliability, it embodies the core principles of modern construction methodology. Whether for small scale or vast construction ventures, the adoption of this technology is a testament to commitment towards quality, efficiency, and sustainability. Choosing the right C to Z purlin roll forming machine requires understanding the specific requirements of your projects. Manufacturers offer machines with varied capabilities in terms of speed, output size, and automation level. Engaging with the right supplier ensures that you access comprehensive support, from installation to operational training, underlying the importance of partnership in achieving optimal outcomes. The C to Z purlin roll forming machine represents a significant leap in technological advancement for the construction industry. Through its enormous value addition, it not only simplifies complex construction processes but significantly enhances the quality of output. Its continued evolution and integration into construction projects worldwide underscore its central role in advancing modern architectural design and implementation.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products