C-Section Frame Roll Forming Machine Manufacturer and Supplier Options

Exploring C Section C Frame Roll Forming Machines A Key to Efficient Manufacturing

In the rapidly evolving landscape of manufacturing, achieving precision and efficiency is crucial. One of the innovative solutions that have emerged to meet these demands is the C Section C Frame Roll Forming Machine. This machinery has revolutionized the way manufacturers produce C-sections, enhancing their ability to create high-quality, uniform products with minimal waste.

What is a C Section C Frame Roll Forming Machine?

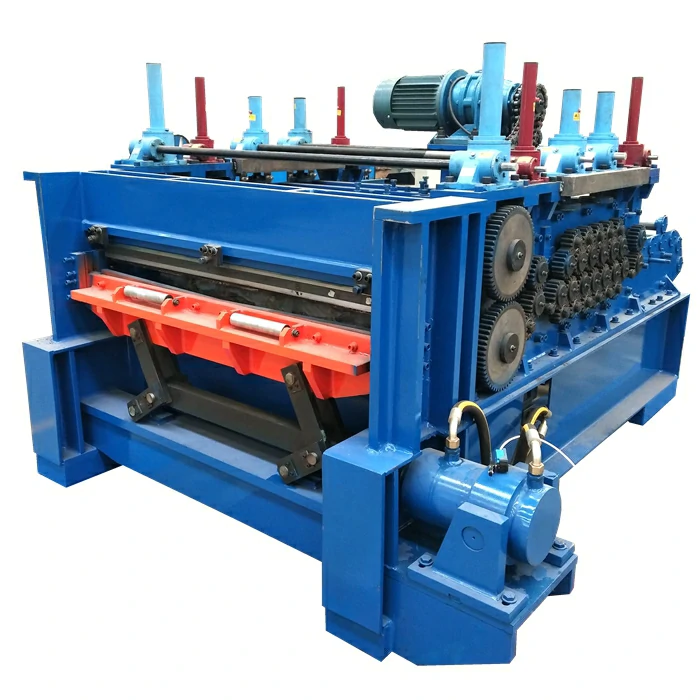

A C Section C Frame Roll Forming Machine is specifically designed to produce a variety of C-shaped profiles, which are widely used in construction, automotive, and various industrial applications. The machine comprises several key components, including roll stands, a feeding mechanism, and cutting tools. The roll stands hold the forming rolls that shape the metal strips into the desired C profile as they pass through.

The process begins with a coil of metal, typically steel or aluminum, which is fed into the machine. As the coil moves through the roll stands, it is gradually shaped into a C-section through a series of progressive forming operations. This method offers several advantages over traditional manufacturing techniques, such as improved consistency and lower labor costs.

Key Benefits of Using C Section C Frame Roll Forming Machines

1. High Efficiency One of the most significant advantages of using a roll forming machine is its ability to produce long lengths of C-sections continuously. Unlike other methods that may require frequent adjustments and downtime, a roll forming machine can operate at high speeds without sacrificing quality.

2. Precision and Consistency Roll forming machines are designed to maintain strict tolerances, ensuring that each C-section produced meets exact specifications. This level of precision is essential in industries where structural integrity is paramount.

3. Material Conservation The roll forming process is highly efficient in terms of material usage. By continuously shaping metal strips, manufacturers can minimize waste, making it an environmentally friendly option. This is particularly important as industries are increasingly pressured to adopt sustainable practices.

c section c frame roll forming machine supplier

4. Versatility While primarily used for C-sections, these machines can also be adapted to produce a variety of different profiles, such as U or Z shapes, by simply changing the roll sets. This versatility allows manufacturers to diversify their product offerings without the need for multiple machines.

5. Automated Functionality Today’s C Frame Roll Forming Machines are often equipped with advanced automation technologies that enhance their functionality. Features such as automatic feeders, hydraulic cutters, and digital controls allow for reduced labor requirements and increased production rates.

Choosing the Right Supplier

When considering the acquisition of a C Section C Frame Roll Forming Machine, it is crucial to select a reputable supplier. The right supplier will provide not only high-quality machinery but also comprehensive support services, including installation, training, and maintenance.

When evaluating suppliers, consider their industry experience, range of products, and customer reviews. A supplier with a proven track record will be better equipped to meet your specific requirements and provide ongoing support as your needs evolve.

Conclusion

The C Section C Frame Roll Forming Machine stands at the forefront of modern manufacturing technology, delivering unparalleled efficiency, precision, and flexibility. As industries continue to demand higher quality and lower costs, these machines offer an effective solution to meet these challenges. By investing in a C Section C Frame Roll Forming Machine from a reliable supplier, manufacturers can ensure they remain competitive in an increasingly demanding marketplace. Embracing this technology not only improves production capabilities but also supports sustainable practices through material conservation and waste reduction.

In summary, if your manufacturing operations require high-quality C-sections, it is time to consider the advantages offered by C Section C Frame Roll Forming Machines. With the right machinery and supplier, you can significantly enhance your production processes and drive your business towards greater success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025