IBR Sheet Roll Forming Machine Manufacturer and Exporter Solutions for Your Needs

The Rise of IBR Sheet Roll Forming Machine Exporters

In recent years, the global demand for lightweight, durable, and cost-effective building materials has surged, and one of the most significant players in this market is the IBR (Inverted Box Rib) sheet roll forming machine. As the construction industry continues to evolve, the role of specialized machinery in producing high-quality building materials has become increasingly critical. This article delves into the significance of IBR sheet roll forming machine exporters and their impact on the construction landscape.

Understanding IBR Sheets

IBR sheets are widely utilized in roofing and wall applications due to their strength, flexibility, and aesthetic appeal. The unique ribbed design not only enhances the structural integrity of buildings but also contributes to efficient water drainage. Additionally, these sheets are lightweight, making them easy to transport and install, which is a considerable advantage for construction companies.

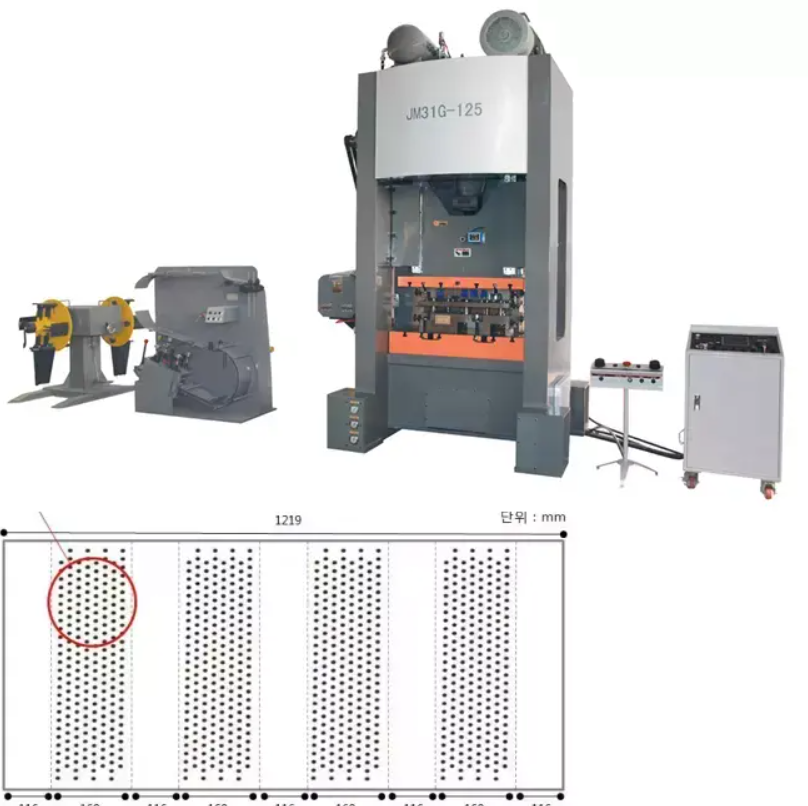

The manufacturing of IBR sheets requires precision machinery, with roll forming machines being the most efficient means of production. These machines take metal strips and convert them into IBR sheets through a series of continuous bending and shaping processes. The versatility and effectiveness of roll forming technology have made it the preferred choice among manufacturers.

The Role of Exporters

The emergence of IBR sheet roll forming machine exporters has transformed the dynamics of the construction material supply chain. Exporters play a vital role in bridging the gap between manufacturers and customers, particularly in regions where local production facilities are limited or unavailable.

ibr sheet roll forming machine exporter

1. Quality Assurance Exporters often source their machines from reputable manufacturers known for their high standards. This assurance of quality translates to better end products for the construction sector. Customers can rely on these exporters to provide machinery that meets international standards, ensuring the durability and efficiency of the IBR sheets produced.

2. Cost Efficiency By engaging with exporters, companies can often access competitive pricing models. Exporters have established networks and partnerships that allow them to procure machinery at lower costs, which they can then pass on to their clients. This cost efficiency is especially critical for small to medium-sized construction firms that may have limited budgets.

3. Technical Support and Training Many exporters do not merely provide machinery; they also offer essential support services, such as installation, maintenance, and training. This assistance ensures that operators can maximize the efficiency of the machines, leading to increased productivity and reduced downtime. Training programs also contribute to better workmanship, resulting in higher quality output.

4. Market Expansion Exporters enable local manufacturers to expand their reach beyond their domestic markets. By providing access to superior machinery, they empower these businesses to produce quality IBR sheets that meet global standards. This capability opens up opportunities for export, contributing to economic growth and job creation in developing regions.

Conclusion

The role of IBR sheet roll forming machine exporters is pivotal in the construction industry. They not only ensure the availability of high-quality machinery but also contribute to the overall efficiency and growth of the sector. As global demands evolve, the importance of these exporters will only increase. They are not just suppliers; they are strategic partners that help shape the future of construction through innovation and quality assurance.

In a world that prioritizes sustainability and efficiency, the advancements in IBR sheet roll forming technology—facilitated by exporters—will continue to play a crucial role in meeting the needs of the modern construction industry. As such, fostering relationships with reliable exporters will be essential for companies looking to stay competitive in the rapidly changing landscape of construction materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025