Cost Analysis of Roll Forming Machine Manufacturers for Optimal Investment Decisions

The Cost of Roll Forming Machines A Comprehensive Overview

Roll forming is a manufacturing process that involves bending metal sheets into specific shapes through a series of rollers. The demand for roll forming machines has grown significantly, driven by the advantages they offer in terms of efficiency, precision, and scalability in production. However, the cost associated with these machines varies based on several factors. In this article, we will explore the different aspects of the cost of roll forming machines, the determinants of pricing, and the considerations for manufacturers.

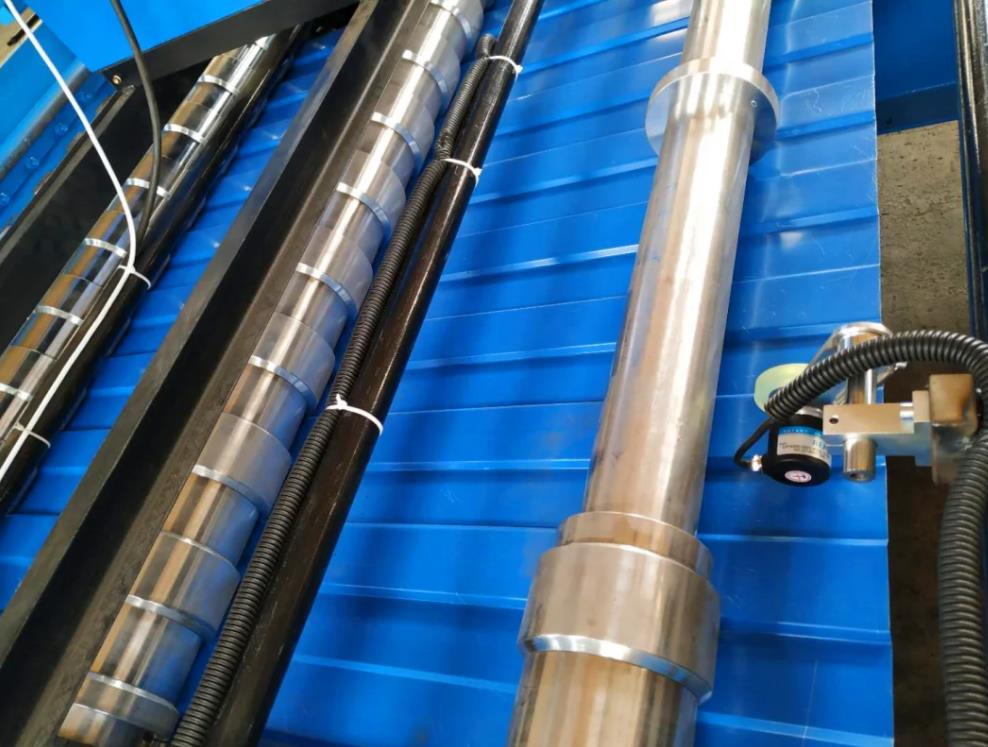

Understanding Roll Forming Machines

Roll forming machines are designed to shape metal strips into long lengths of desired profiles. These machines can produce a wide range of finished products, including roofing sheets, purlins, and various structural components used in construction and automotive industries. The versatility and efficiency of roll forming make these machines a staple in many manufacturing sectors.

Factors Influencing the Cost

1. Type of Machine The cost of roll forming machines is primarily determined by their type. There are several categories including conventional roll formers, high-speed roll formers, and custom-designed machines. Conventional models are generally less expensive, while high-speed and custom machines typically come with a higher price tag due to their advanced technology and the complexity of design.

2. Material Quality The construction materials used in the machine significantly impact the overall cost. Machines made from high-quality steel and components that ensure durability and longevity tend to be more expensive but offer better performance and reduced maintenance costs over time.

3. Automation Level The degree of automation incorporated into the roll forming machine also affects its price. Machines that come equipped with advanced automation features—such as programmable logic controllers (PLCs), sensors, and integrated quality control systems—tend to be pricier. However, they can lead to improved productivity and decreased labor costs.

cost of roll forming machine manufacturer

4. Customization and Design Complexity Custom machines, tailored to specific production needs, often require significant engineering and design work. This customization increases both the upfront costs and the lead time for delivery. The complexity of the design, including the number of stations (rollers) and adjustments required for different profiles, can also influence the overall pricing.

5. Production Capacity Machines with higher production capacities tend to have a higher cost. Manufacturers need to consider their production volume when investing in roll forming equipment. For businesses that require high throughput, the initial expense of a more expensive, high-capacity machine may be justified.

6. Brand and Reputation The manufacturer’s reputation can play a critical role in the pricing of roll forming machines. Established brands with a history of reliability and performance may charge a premium for their products, while lesser-known manufacturers may offer lower prices but with a varying degree of quality and support.

Investment and Return on Investment (ROI)

Investing in a roll forming machine is a significant decision for any manufacturer, and understanding the cost implications is crucial. While the initial expenditure can be considerable, the potential for long-term savings and increased profitability should not be overlooked. High-efficiency machines can reduce production time, minimize waste, and lower labor costs, making them a smart investment.

Additionally, businesses should evaluate the potential market for their products. If the roll forming machine enables them to diversify their product offerings and tap into new markets, the ROI may be significantly enhanced.

Conclusion

The cost of roll forming machines varies widely based on several influencing factors, including the type of machine, material quality, level of automation, customization needs, production capacity, and manufacturer reputation. For businesses considering such an investment, evaluating these factors alongside potential returns is essential for making an informed choice. By understanding the landscape of roll forming machine costs, manufacturers can better navigate their purchasing decisions and position themselves for success in a competitive market. As technology continues to evolve, staying informed about advancements in roll forming equipment will help businesses maintain their edge in the manufacturing sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025