gutter rolling machine factories

The Importance of Gutter Rolling Machine Factories in Modern Construction

In the world of modern construction and architectural design, the need for efficient and precise manufacturing processes is paramount. One crucial component in this realm is the gutter rolling machine, a specialized piece of equipment used to produce gutters and downspouts in various shapes and sizes. This article delves into the significance of gutter rolling machine factories, their operational processes, and their impact on the construction industry.

Understanding Gutter Rolling Machines

Gutter rolling machines are engineered to manufacture gutters from a variety of materials, primarily aluminum, steel, and copper. These machines utilize advanced techniques to roll sheets of metal into the desired shape, allowing for seamless and high-quality production. The versatility of gutter rolling machines makes them indispensable in both residential and commercial projects, as they can create customized solutions tailored to specific architectural requirements.

The Role of Gutter Rolling Machine Factories

Gutter rolling machine factories play a vital role in ensuring a steady supply of materials needed for construction projects. These factories operate on both small and large scales, producing everything from standard gutter profiles to bespoke designs requested by contractors and architects. Their operations typically range from initial metal sheet procurement to the final rolled product, with a focus on quality control at each step.

1. Manufacturing Process Gutter rolling machine factories employ a series of processes to transform raw metal sheets into finished gutters. The journey begins with the selection of high-quality materials that meet industry standards for durability and resistance to corrosion. Once the sheets are prepared, they are fed into the rolling machines, where they are shaped into the desired profile. Advanced technology allows for precision cuts, ensuring that the finished products fit seamlessly into the intended applications.

gutter rolling machine factories

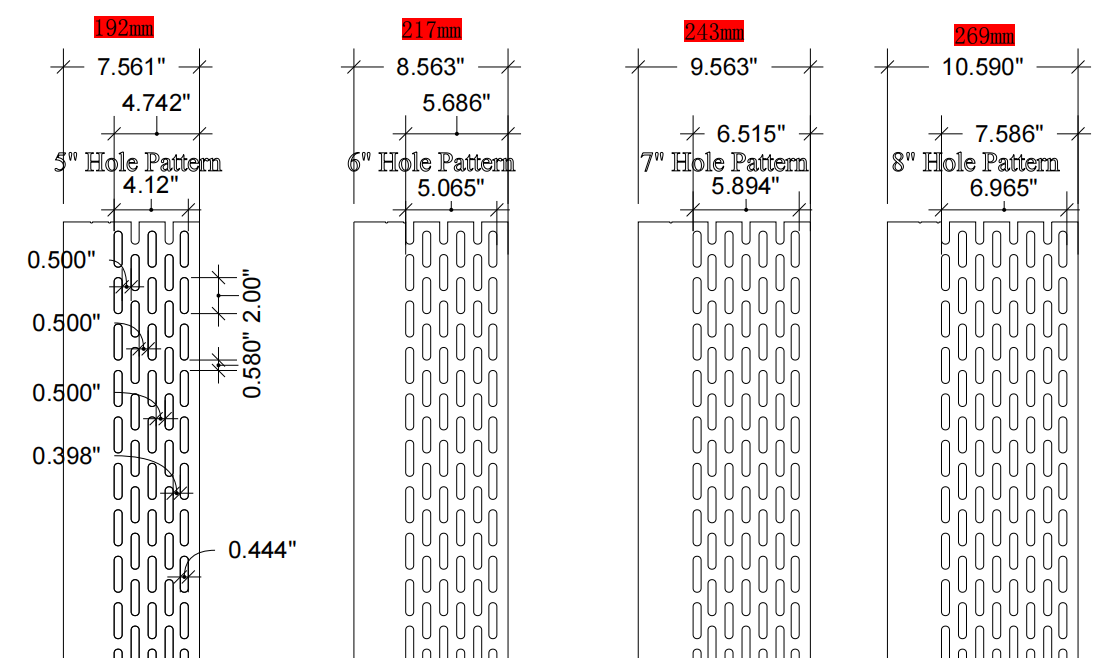

2. Customization and Innovation One of the standout features of gutter rolling machine factories is their ability to provide customized products. As architects and builders often require specific dimensions and designs, these factories invest in flexible manufacturing systems that can be quickly adjusted to produce varied profiles. Furthermore, innovation in gutter design—such as improved drainage capabilities and aesthetic features—has driven factories to continuously update their machinery and techniques.

3. Economic Impact Gutter rolling machine factories are not only crucial for the construction itself but also play an important economic role. They create jobs and contribute to local economies by offering employment opportunities ranging from machine operators to engineers. Moreover, by producing locally, these factories help reduce transportation costs and carbon footprints associated with importing materials.

Challenges Facing Gutter Rolling Machine Factories

Despite their importance, gutter rolling machine factories face several challenges. Fluctuations in raw material prices can impact production costs, while the need for consistent quality can strain operations. Additionally, the increasing emphasis on sustainability in construction pushes these factories to adopt greener practices, which may require significant investments in new technology.

Conclusion

In conclusion, gutter rolling machine factories are a foundational element of the construction industry, providing essential materials with a balance of quality, efficiency, and customization. As demand for diverse and sustainable building solutions grows, these factories will continue to evolve, adopting innovative practices that enhance their productivity while addressing environmental concerns. Their contribution to the construction sector not only supports the industry’s growth but also fosters advancements in architectural design that cater to modern needs. Through understanding and investing in these manufacturing facilities, stakeholders can ensure a robust and sustainable future for construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025