Corrugated Roofing Sheet Production Equipment Manufacturer and Supplier

The Rise of Corrugated Roof Sheet Machine Factories

In the world of construction and building materials, corrugated roofing sheets have gained significant popularity due to their durability, affordability, and aesthetic appeal. The production of these sheets is facilitated by specialized machines designed to streamline and enhance the manufacturing process. As the demand for lightweight, strong roofing materials continues to rise, corrugated roof sheet machine factories are emerging as pivotal players in the industry.

Understanding Corrugated Roofing Sheets

Corrugated roofing sheets are typically made from materials such as metal, fiberglass, or polycarbonate. Their unique wavy design not only provides structural strength but also facilitates effective water drainage, making them ideal for various climates. The installation of these sheets is relatively straightforward, contributing to their appeal among DIY enthusiasts and professional builders alike. Given the myriad benefits—ranging from cost-effectiveness to versatility in application—the demand for corrugated roofing sheets is surging globally.

The Role of Machinery in Production

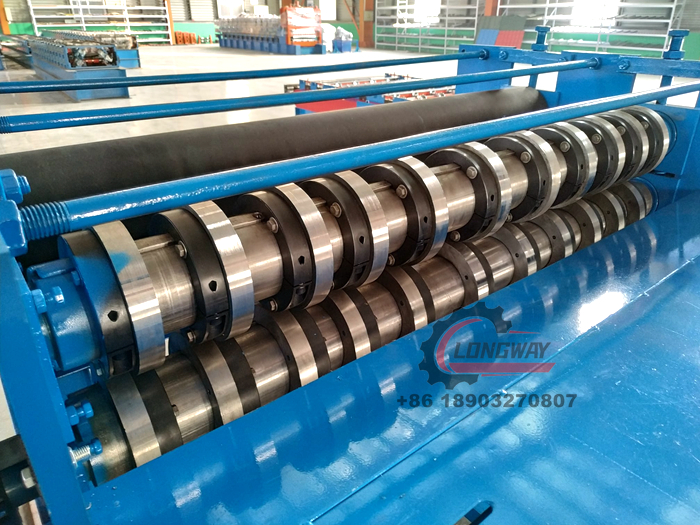

To meet the growing demand, corrugated roof sheet machine factories focus on the production of advanced machinery that enhances efficiency and output

. These machines are engineered to handle a variety of materials, including galvanized steel and aluminum, and can produce sheets of varying profiles and thicknesses.The manufacturing process often involves several key stages material feeding, forming, cutting, and finishing. Automated systems ensure that each stage is executed with precision, resulting in high-quality products. Modern factories are increasingly adopting computer numerical control (CNC) technology to enhance accuracy and reduce waste. This technological evolution not only streamlines production but also minimizes labor costs, enabling factories to offer competitive prices.

Environmental Considerations

corrugated roof sheet machine factory

In today's market, sustainability is a vital theme. Many corrugated roof sheet machine manufacturers are adapting their processes to be more environmentally friendly. This includes utilizing recycled materials in the production of sheets and implementing energy-efficient machinery. Companies are also adopting practices such as water recycling and waste management systems to minimize their environmental footprint.

Innovative technologies in manufacturing are yielding eco-friendly roofing solutions that appeal to a growing segment of environmentally conscious consumers. This shift not only secures a competitive edge but also aligns with global efforts to promote sustainable building practices.

Market Trends and Future Prospects

As urbanization accelerates worldwide, particularly in emerging economies, the demand for corrugated roof sheet machines is expected to grow significantly. The construction industry's shift toward cost-efficiency and sustainability is driving innovation in machine design and functionality. Factories are exploring the integration of IoT and AI technologies to enhance production capabilities and gather insightful data that can improve efficiency.

Additionally, the rise of e-commerce platforms enables manufacturers to reach broader markets, allowing them to cater to both local and international customers. Access to diverse markets is not only a lucrative opportunity but also a way to foster healthy competition, further propelling advancements in technology within the industry.

Conclusion

As the construction landscape continues to evolve, corrugated roof sheet machine factories find themselves at the forefront of innovation and sustainability. The combination of advanced machinery, environmentally conscious practices, and a growing global demand for efficient building materials positions these factories as key contributors to the construction sector.

Investing in the development of cutting-edge machinery and adhering to sustainable practices will be crucial for manufacturers looking to thrive in this dynamic environment. In the future, the synergy between technology, environmental stewardship, and market needs will define the trajectory of corrugated roof sheet production, ensuring that these factories play a critical role in shaping the industry. As we move forward, it is clear that the corrugated roof sheet machine factories will not only meet the demands of today but also pave the way for a more sustainable and efficient future in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025