Innovative Solutions for Standing Seam Metal Fabrication and Machinery Production

Standing Seam Metal Roof Systems An Overview of Innovations and Companies in the Industry

In the world of construction and architecture, standing seam metal roofs have emerged as a leading choice for both new builds and renovations. Their durability, aesthetics, and energy efficiency make them a coveted option for various types of buildings, from residential homes to commercial structures. As the demand for these roofing systems grows, so does the need for reliable manufacturers specializing in standing seam metal machines. This article explores the innovations within the industry and highlights some notable companies leading the charge in standing seam metal machine production.

Standing seam metal roofs consist of continuous vertical panels connected by interlocking seams. This design not only enhances the roof’s durability but also allows for effective water drainage, making it ideal for regions with heavy rainfall or snow. One of the primary advantages of a standing seam metal roof is its ability to expand and contract with temperature fluctuations without compromising the integrity of the seal. This flexibility contributes to the longevity of the roof, often lasting over 50 years with proper maintenance.

Standing Seam Metal Roof Systems An Overview of Innovations and Companies in the Industry

One prominent player in the standing seam metal machine industry is New Tech Machinery (NTM), based in Denver, Colorado. NTM is well-known for producing a wide range of portable and customizable roll-forming machines specifically designed for standing seam metal roofing. Their industry-leading machines are engineered for ease of use, allowing contractors to operate them with minimal training. Furthermore, NTM offers a comprehensive support system, empowering customers with resources and knowledge to maximize their equipment's capabilities.

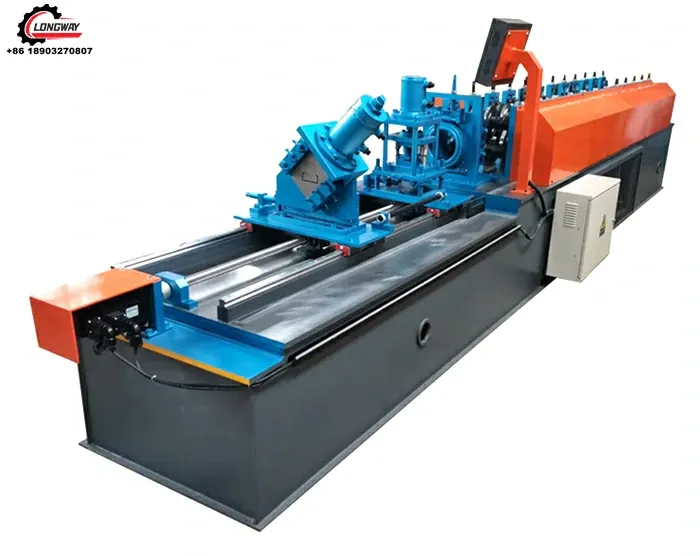

standing seam metal machine company

Another significant company is Whirlwind Steel Buildings, which manufactures a diverse array of metal building systems, including standing seam roof systems. Whirlwind Steel stands out for incorporating cutting-edge technology into their manufacturing processes, producing machinery with an emphasis on efficiency and sustainability. Their commitment to innovation keeps them at the forefront of the industry, as they continuously adapt to changing market demands.

Kalzip, a global leader in the production of standing seam roof systems, also contributes significantly to the machinery market. Known for their state-of-the-art engineering and high-quality materials, Kalzip offers not only exceptional roofing systems but also the machinery needed for effective implementation. They specialize in providing comprehensive solutions, from the initial design phase through to the installation of the roofing system, ensuring that their clients are equipped with the best tools and technologies.

Moreover, as sustainability becomes a better focus in the construction industry, standing seam metal manufacturers are exploring eco-friendly practices. Many leading companies are now offering machines that utilize recycled materials or produce minimal waste during manufacturing. This trend not only caters to the growing market of environmentally conscious customers but also helps construction firms meet strict green building standards.

In conclusion, standing seam metal roofs represent the pinnacle of modern roofing solutions, combining durability, functionality, and aesthetic appeal. Companies specializing in standing seam metal machines play a crucial role in advancing this industry, providing contractors with the tools they need to deliver top-notch roofing systems. As technology continues to evolve, these manufacturers remain dedicated to quality and innovation, ensuring that standing seam metal roofs will remain a preferred choice in the architectural landscape for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025