Jan . 28, 2025 03:36

Back to list

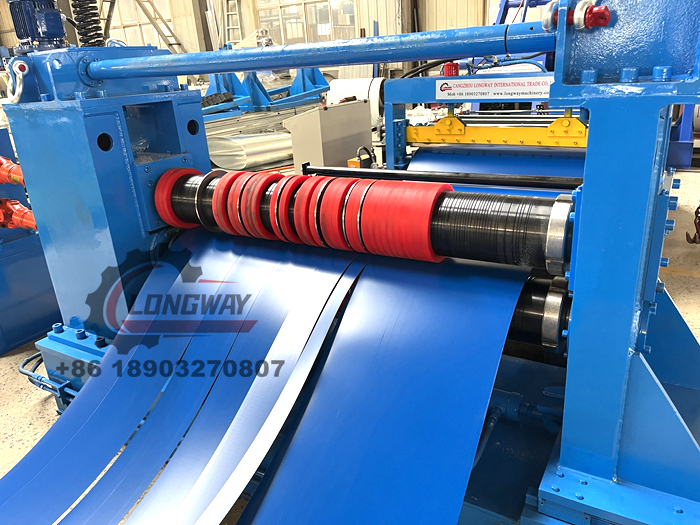

corrugated roof sheet machine

For those venturing into the industry of roofing solutions, the corrugated roof sheet machine represents a pivotal innovation that has transformed the landscape of modern construction. With its roots deeply embedded in the need for efficiency and precision, this machine has become indispensable in crafting roofing materials that are both durable and aesthetically pleasing. The growing demand for high quality, customized roofing sheets has amplified the necessity for these machines in various sectors, guiding us through their importance and functionality.

Practitioners with substantial experience emphasize the necessity of routine maintenance and timely upgrades. Trustworthiness in these machines primarily stems from adhering to a regular maintenance schedule, which not only prolongs their lifespan but also guarantees consistent product quality. Manufacturers often offer comprehensive service packages, ensuring machines operate at peak efficiency while providing training for users to maximize potential output and minimize downtime. In terms of trustworthiness, it's crucial to select machines from manufacturers who have been meticulously vetted for their reliability and quality. Reputable companies provide extensive warranties and have a track record of innovation and customer satisfaction. Reviews and case studies are invaluable resources for potential buyers to assess the experiences of other users, offering a glimpse into the machine's real-world performance and longevity. The evolution of corrugated roof sheet machines continues, driven by the constant demand for enhanced efficiency and versatility. The transition toward automation has enabled these machines to operate with minimal supervision, drastically improving production rates. This shift not only reduces labor costs but also mitigates human error, aligning with the industry's push towards precision manufacturing. In conclusion, the corrugated roof sheet machine exemplifies a perfect blend of technology and craftsmanship. Its role in producing reliable, high-strength roofing materials has cemented its place as an indispensable asset in architecture and construction. For industry players and newcomers alike, understanding the intricacies of these machines is crucial in navigating the roofing sector successfully. By investing in modern, reliable machinery and upholding stringent maintenance practices, enterprises can ensure an edge in quality assurance and product excellence.

Practitioners with substantial experience emphasize the necessity of routine maintenance and timely upgrades. Trustworthiness in these machines primarily stems from adhering to a regular maintenance schedule, which not only prolongs their lifespan but also guarantees consistent product quality. Manufacturers often offer comprehensive service packages, ensuring machines operate at peak efficiency while providing training for users to maximize potential output and minimize downtime. In terms of trustworthiness, it's crucial to select machines from manufacturers who have been meticulously vetted for their reliability and quality. Reputable companies provide extensive warranties and have a track record of innovation and customer satisfaction. Reviews and case studies are invaluable resources for potential buyers to assess the experiences of other users, offering a glimpse into the machine's real-world performance and longevity. The evolution of corrugated roof sheet machines continues, driven by the constant demand for enhanced efficiency and versatility. The transition toward automation has enabled these machines to operate with minimal supervision, drastically improving production rates. This shift not only reduces labor costs but also mitigates human error, aligning with the industry's push towards precision manufacturing. In conclusion, the corrugated roof sheet machine exemplifies a perfect blend of technology and craftsmanship. Its role in producing reliable, high-strength roofing materials has cemented its place as an indispensable asset in architecture and construction. For industry players and newcomers alike, understanding the intricacies of these machines is crucial in navigating the roofing sector successfully. By investing in modern, reliable machinery and upholding stringent maintenance practices, enterprises can ensure an edge in quality assurance and product excellence.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products