Jan . 24, 2025 03:47

Back to list

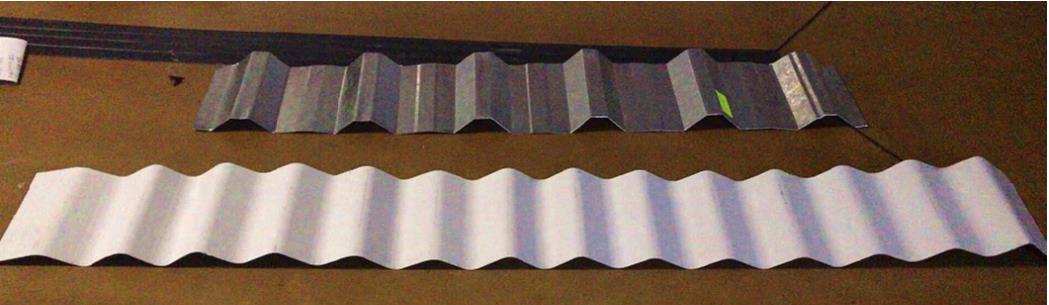

corrugated iron roofing sheet making machine

Investing in a corrugated iron roller machine can revolutionize your business by enhancing productivity and ensuring the superior quality of finished products. With applications spanning industries from construction to manufacturing, these machines are essential for producing corrugated iron sheets used in building roofs, walls, and other structural components.

The authoritativeness of selecting the right corrugated iron roller machine for sale cannot be overstated. Consulting with manufacturers and industry experts provides insights into the machine's adaptability to various materials and thicknesses, thus ensuring it meets specific operational demands. Additionally, reputable brands often provide training and support to operators, enhancing the reliability and lifespan of the machine and ensuring it meets industry standards for safety and performance. Trustworthiness in choosing the right supplier is similarly essential as it can affect your business's operational efficiency long-term. Key considerations should include the manufacturer’s reputation, warranty coverage, after-sales service, and availability of spare parts. It's advisable to seek customer testimonials and professional reviews to gauge the satisfaction and issues faced by other buyers. The best suppliers not only offer high-quality machines but also maintain a comprehensive support network for troubleshooting and maintenance guidance. In summary, purchasing a corrugated iron roller machine is an investment that requires careful consideration of experience, expertise, authoritativeness, and trustworthiness. By understanding these factors and selecting the right model, you position your business for enhanced efficiency, reduced production costs, and improved product quality. As technology advances, embracing such equipment will cater to growing market needs and solidify your position in the industry.

The authoritativeness of selecting the right corrugated iron roller machine for sale cannot be overstated. Consulting with manufacturers and industry experts provides insights into the machine's adaptability to various materials and thicknesses, thus ensuring it meets specific operational demands. Additionally, reputable brands often provide training and support to operators, enhancing the reliability and lifespan of the machine and ensuring it meets industry standards for safety and performance. Trustworthiness in choosing the right supplier is similarly essential as it can affect your business's operational efficiency long-term. Key considerations should include the manufacturer’s reputation, warranty coverage, after-sales service, and availability of spare parts. It's advisable to seek customer testimonials and professional reviews to gauge the satisfaction and issues faced by other buyers. The best suppliers not only offer high-quality machines but also maintain a comprehensive support network for troubleshooting and maintenance guidance. In summary, purchasing a corrugated iron roller machine is an investment that requires careful consideration of experience, expertise, authoritativeness, and trustworthiness. By understanding these factors and selecting the right model, you position your business for enhanced efficiency, reduced production costs, and improved product quality. As technology advances, embracing such equipment will cater to growing market needs and solidify your position in the industry.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products