China Foot Pedal Operated Roll Forming Machine for Efficient Metal Fabrication Solutions

The Innovation of China Foot Pedal Roll Forming Machine

In recent years, the manufacturing industry has seen remarkable advancements, particularly in the field of machinery. One such innovation is the foot pedal roll forming machine, a device that has gained recognition for its efficiency and versatility in various applications. Made prominent by Chinese manufacturers, this machine has revolutionized how metal products are fabricated, providing significant improvements in quality and production speed.

What is a Foot Pedal Roll Forming Machine?

A foot pedal roll forming machine is a specialized piece of equipment used to shape metal sheets into predetermined profiles. The machine operates on the principle of continuous bending and forming, with the foot pedal serving as a control mechanism that allows operators to easily manage the formation process. This hands-free operation increases productivity, as the operator can focus on guiding and feeding the material through the machine.

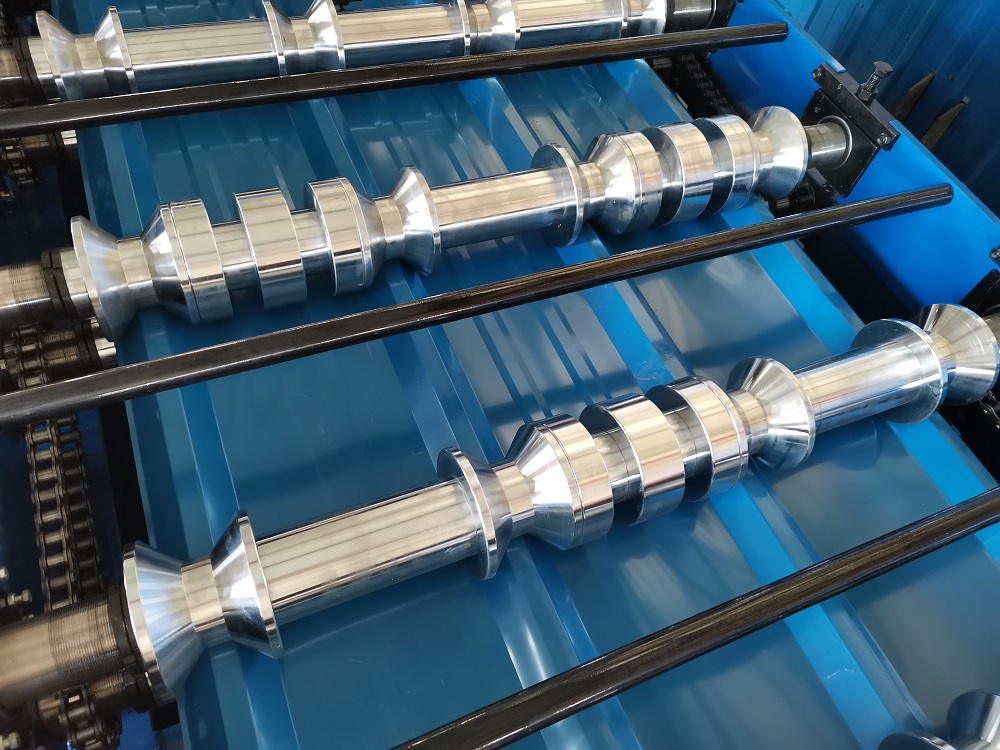

Typically, these machines are equipped with multiple rollers that gradually shape the metal as it passes through various stages. The operation starts with a flat metal sheet, which is fed into the machine. The rollers apply pressure to bend the sheet into the desired shape, creating components used in numerous industries such as construction, automotive, and HVAC (heating, ventilation, and air conditioning).

Advantages of the Foot Pedal Roll Forming Machine

Chinese manufacturers have perfected the design and functionality of foot pedal roll forming machines, making them a preferred choice for businesses globally. Several advantages contribute to their popularity

1. Efficiency Traditional manual methods of bending and shaping metal can be time-consuming and require significant labor. The foot pedal mechanism allows for rapid operation, enabling one operator to manage multiple tasks simultaneously. This efficiency not only saves time but also reduces labor costs.

china foot pedal roll forming machine

2. Precision and Consistency The roll forming process ensures uniformity in the final product. The design of the rollers allows for precise shaping, meaning that all pieces produced are consistent in size and quality. This level of precision is crucial in industries where specifications must be strictly adhered to.

3. Space-Saving Design Many foot pedal roll forming machines are compact and can fit into smaller workspaces, making them ideal for businesses with limited floor space. This design enables manufacturers to maximize productivity without needing extensive factory space.

4. Versatility These machines can be adjusted to create various shapes and sizes, making them suitable for multiple applications. Manufacturers can easily switch between projects without investing in new machinery, thereby increasing their ability to meet diverse customer needs.

5. Durability and Low Maintenance Chinese manufacturers are known for producing high-quality machinery, and foot pedal roll forming machines are no exception. Generally built from high-grade materials, these machines are durable and require minimal maintenance, providing long-term reliability for businesses.

Applications in Various Industries

Foot pedal roll forming machines find applications in a wide range of industries. In the construction sector, they are used to create metal frames, roofing materials, and structural components. The automotive industry utilizes these machines for producing parts such as reinforcements and chassis components. Additionally, HVAC manufacturers employ roll forming machines to produce ductwork and other related products.

Conclusion

The foot pedal roll forming machine represents a significant technological advancement in the metal fabrication industry. Its efficiency, precision, and versatility make it an invaluable tool for manufacturers looking to enhance productivity and output quality. As Chinese manufacturers continue to innovate and optimize these machines, their impact on the global market is expected to grow. Companies that invest in foot pedal roll forming technology will likely see improved operational capabilities, enabling them to meet diverse market demands more effectively. As the industry evolves, embracing such innovations will be crucial for staying competitive in today’s fast-paced manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025