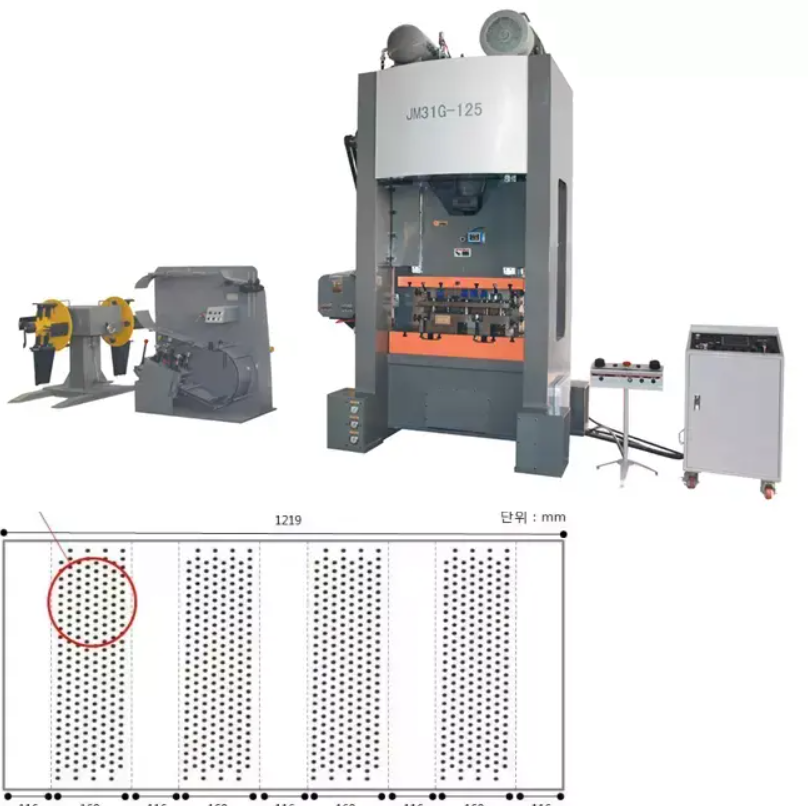

highway guardrail making machine

The Highway Guardrail Making Machine Enhancing Road Safety

Highway safety has become a crucial concern as traffic volumes continue to rise globally. One essential component in ensuring the safety of road users is highway guardrails. These barriers serve a vital role in preventing vehicles from veering off the road and protecting occupants during collisions. The efficacy of guardrails largely depends on their design and manufacturing processes. This is where the highway guardrail making machine comes into play, revolutionizing the production of these safety features.

The highway guardrail making machine is designed to streamline the manufacturing process, ensuring that guardrails are produced quickly, efficiently, and to exact specifications. These machines typically operate using advanced technology, incorporating techniques such as rolling and welding to shape high-strength steel into durable guardrail designs. By utilizing processes like cold roll forming, manufacturers can create guardrails that comply with stringent safety standards while minimizing material wastage.

One of the key advantages of using a highway guardrail making machine is the precision it offers. Modern machines are equipped with computer numerical control (CNC) systems, allowing for highly accurate production of guardrails that meet specific design parameters. This precision is critical, as even minor deviations can compromise a guardrail's performance during an impact. With the ability to produce guardrails tailored to various road conditions and safety requirements, manufacturers can significantly enhance road safety.

highway guardrail making machine

Moreover, the use of automated machinery in guardrail production leads to increased productivity. Traditional methods often rely on manual labor, which can be time-consuming and prone to errors. In contrast, a highway guardrail making machine can operate continuously, reducing production times and meeting higher demand levels. This automation not only helps in scaling up production but also reduces labor costs, making the overall process more economically viable for manufacturers.

In addition to enhancing efficiency and precision, these machines can also contribute to sustainability in manufacturing. Many highway guardrail making machines are designed to utilize scrap materials effectively, thereby minimizing waste. By recycling metal during the production process, manufacturers can lessen their environmental impact while still producing high-quality guardrails.

Furthermore, investing in advanced guardrail manufacturing machines not only benefits manufacturers but also contributes significantly to public safety. With robust and well-designed guardrails in place, the chances of severe accidents on highways can be minimized. This improvement in safety can lead to reduced injury claims, lower healthcare costs, and overall better outcomes for road safety.

In conclusion, the highway guardrail making machine plays a crucial role in producing essential safety products for roadways. By leveraging technology to enhance precision, efficiency, and sustainability, these machines are transforming the guardrail manufacturing industry. As road safety continues to be a pressing concern worldwide, the importance of investing in advanced manufacturing solutions cannot be overstated. With better guardrails, we can aspire to make our roads safer for everyone.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025