cheap roofing roll forming machine price

Understanding the Cost of Cheap Roofing Roll Forming Machines

In the competitive building and construction industry, the demand for durable, cost-effective roofing materials has surged in recent years. As a result, the roofing business has seen significant advancements in manufacturing technology. One key piece of equipment witnessing rising popularity is the roofing roll forming machine. This article will explore what these machines are, the factors affecting their prices, and how businesses can benefit from choosing inexpensive options without compromising on quality.

What is a Roofing Roll Forming Machine?

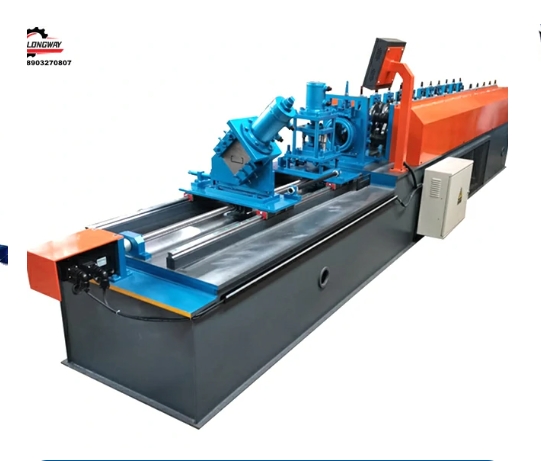

A roofing roll forming machine is a specialized industrial machine used to produce metal roofing materials. It works by continuously feeding metal coils into forming rollers, which then shape the material into specific profiles designed for roofing applications. These machines can create a wide variety of roof panel designs, including standing seam, corrugated sheets, and ridge caps, tailored to meet various architectural and functional requirements.

Factors Influencing Prices

When considering the price of roofing roll forming machines, it's crucial to recognize several factors that contribute to cost variations

1. Material Quality The types of materials used in the manufacturing process significantly impact pricing. Machines made from high-quality steel or aluminum tend to be more expensive but offer greater durability and performance.

2. Machine Capacity The output capacity of the machine, measured in terms of speed and volume, directly influences its price. High-capacity machines that can handle larger production volumes typically cost more than smaller, less efficient models.

3. Customization Options Machines that can produce a variety of profiles or can be easily adjusted to create different product lines tend to have higher price tags. Customization provides flexibility but also increases complexity and cost.

4. Technology and Automation Advanced features, such as computer numerical control (CNC) or other automation technologies, might raise the upfront cost. However, these machines can significantly enhance productivity and accuracy, potentially leading to cost savings in the long run.

cheap roofing roll forming machine price

5. Brand Reputation Well-known brands often charge more due to their reputation for reliability, warranty options, and customer service. While investing in a reputable brand can be wise, it’s also possible to find less known but equally efficient machines at lower prices.

Benefits of Choosing Cheaper Roofing Roll Forming Machines

Opting for a less expensive roofing roll forming machine does not automatically result in inferior quality. Here are some benefits associated with considering cheaper options

1. Cost Savings Lower initial investments can allow small to medium-sized businesses to enter the roofing market without significant financial pressure. This can be particularly beneficial for startups or companies looking to expand without incurring heavy debts.

2. Improved Cash Flow Investing in more affordable machines may enhance a company’s cash flow, allowing funds to be allocated towards other areas of the business, such as marketing or workforce training.

3. Access to Technology Many manufacturers are offering advanced technologies at lower prices due to increased competition. Businesses can now access high-quality machines with modern features without breaking the bank.

4. Variety of Options The growing number of suppliers, especially in countries with lower production costs, means that there are many options available. Business owners can shop around to find the best deals that meet their specifications and budget.

Conclusion

Choosing a roofing roll forming machine involves a careful analysis of price versus quality. While the market offers cheaper options, these machines can still provide excellent performance and durability. By understanding the factors that influence pricing and recognizing that cost-effective solutions can still deliver reliability, businesses can make informed purchasing decisions. Investing wisely in equipment can lead to increased productivity, better quality products, and ultimately, greater customer satisfaction in the roofing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025