corrugated sheet pressing machine companies

The Emerging Market of Corrugated Sheet Pressing Machines

In recent years, the construction and packaging sectors have witnessed substantial growth, leading to a burgeoning demand for efficient and reliable machinery. Among the essential tools in this industry are corrugated sheet pressing machines, which play a crucial role in producing corrugated sheets for various applications, including packaging, construction, and insulation. As the market continues to evolve, numerous companies are entering this niche, providing innovative solutions to meet the needs of diverse industries.

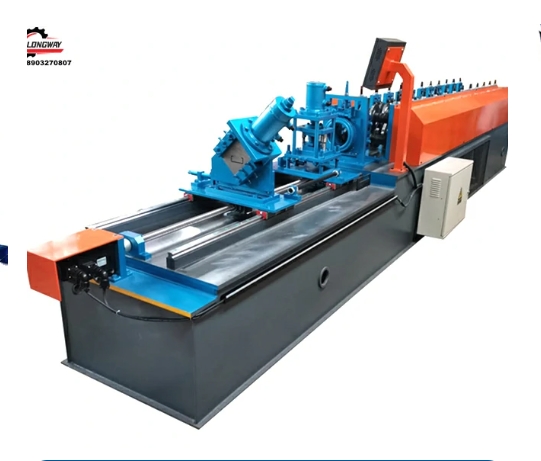

Corrugated sheet pressing machines are specifically designed to manufacture corrugated sheets from raw materials, primarily paper and cardboard. These machines utilize advanced technology to ensure that the sheets produced are not only durable but also lightweight, making them ideal for transportation and packaging. Companies specializing in this machinery invest heavily in research and development to enhance the efficiency, speed, and quality of their products. This focus on innovation is crucial as businesses seek to optimize their processes and reduce production costs.

Several prominent companies dominate the corrugated sheet pressing machine market, each with its unique offerings. For instance, manufacturers like BHS Corrugated, which has a strong presence in Europe, provide a range of options from small-scale machines for local businesses to high-capacity systems for large enterprises. Their commitment to sustainability and energy efficiency has garnered them a loyal customer base, especially as eco-friendly practices become increasingly important in the industry.

Another noteworthy player is Fosber Group, known for its cutting-edge technology and innovative designs. Their machines are lauded for their user-friendly interfaces and low maintenance requirements, which reduce downtime and enhance productivity for operators. In addition to traditional pressing machines, Fosber also offers integrated solutions that combine multiple processes, allowing companies to streamline their operations.

corrugated sheet pressing machine companies

In Asia, particularly in countries like China and India, the demand for corrugated sheet pressing machines is witnessing rapid growth. Local companies are emerging, providing cost-effective alternatives while maintaining acceptable quality standards. These manufacturers often focus on customizing their machines to meet the specific needs of regional markets. As these companies expand, they are increasingly investing in advanced technology to compete with established international brands.

The integration of automation and smart technology into corrugated sheet pressing machines is a notable trend in the industry. Companies are now developing machines equipped with sensors, IoT capabilities, and predictive maintenance features. These advancements allow operators to monitor machine performance in real-time, predict potential failures, and ensure optimal operation. Such innovations not only enhance productivity but also reduce overall operational costs, making machinery more appealing to potential buyers.

Moreover, the growing emphasis on sustainability is reshaping the landscape of corrugated sheet production. Companies are sourcing raw materials responsibly, recycling waste, and developing machines that minimize energy consumption. This shift is largely driven by consumer preferences for environmentally friendly products and the regulatory push for sustainable practices across various industries.

As we move forward, the future of corrugated sheet pressing machine manufacturers appears promising. With the continuous advancement of technology and the increasing demand for eco-friendly solutions, companies that can innovate and adapt will likely gain a competitive edge. The landscape is taking shape for companies to not only expand their market presence but also contribute positively to environmental sustainability.

In conclusion, the corrugated sheet pressing machine market is poised for significant growth due to rising industrial requirements and the increasing importance of sustainability. Companies operating in this sector must embrace technological innovations, focus on customer needs, and prioritize environmental considerations to thrive in an ever-changing market landscape. Future advancements in machine efficiency and the integration of smart technologies will undoubtedly shape a more productive and sustainable future for the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025