Affordable Aluminum Roll Forming Solutions for Your Project Needs and Budget Constraints

The Advantages of Cheap Roll Forming Aluminum A Cost-Effective Solution for Modern Industries

In the ever-evolving manufacturing landscape, the demand for efficient, versatile, and economical production methods has led to the increased popularity of roll forming, particularly with materials like aluminum. Roll forming is a continuous bending operation in which a long strip of metal (in this case, aluminum) is passed through a series of rollers to create a specific profile. When this process is combined with the pursuit of affordability—often referred to as cheap roll forming aluminum—manufacturers can leverage numerous advantages that contribute to both cost savings and operational efficiency.

Understanding Roll Forming

Before delving into the benefits of cheap roll forming aluminum, it's crucial to understand what roll forming entails. The process begins with flat aluminum sheets, which are fed into the roll forming machine. As the aluminum passes through multiple sets of rollers, it gradually takes on the desired shape through a series of bends. This process can yield complex profiles with excellent dimensional accuracy and repeatability, making it highly sought after in various industries.

Economic Benefits

One of the most appealing aspects of cheap roll forming aluminum is its cost-effectiveness. Traditional manufacturing methods for aluminum components, such as extrusion or machining, can be resource-intensive and expensive due to material waste and longer lead times. In contrast, roll forming minimizes waste, as it utilizes continuous strips of aluminum, ensuring that almost every portion of the material is transformed into the final product.

Moreover, the efficiency of the roll forming process translates into lower labor costs. Once the initial tooling is set up, the production process can run continuously, requiring minimal manual intervention. This not only speeds up production but also reduces labor expenses, which can be particularly beneficial for companies operating on tight budgets or those looking to optimize their profit margins.

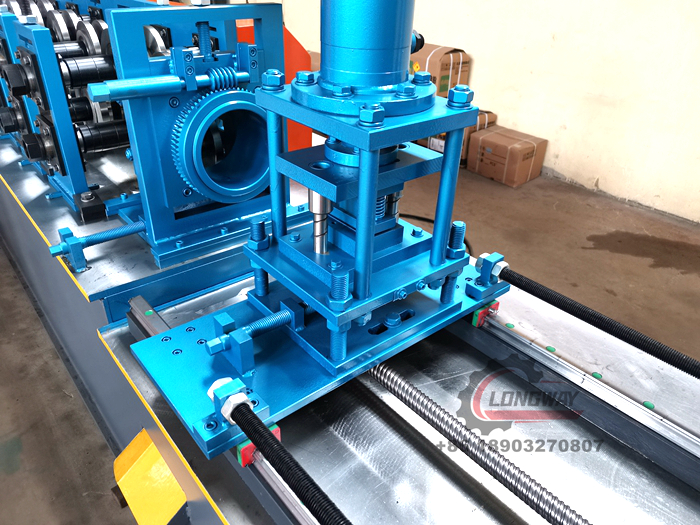

cheap roll forming aluminum

Versatility and Customization

Another significant advantage of cheap roll forming aluminum is its versatility. Manufacturers can produce a wide range of profiles tailored to specific applications, from simple shapes to more intricate designs. This level of customization is particularly valuable in industries such as construction, automotive, and consumer goods, where the demand for unique aluminum components is high.

Additionally, roll forming can accommodate a variety of aluminum alloys, allowing manufacturers to choose materials best suited for their specific applications. Whether it's a lightweight profile for an automotive part or a more robust structure for a building project, roll forming provides the flexibility needed to meet diverse industry requirements.

Environmental Considerations

In today's environmentally conscious marketplace, the sustainability of manufacturing processes is of paramount importance. Cheap roll forming aluminum aligns well with this trend, as aluminum itself is a highly recyclable material. The roll forming process generates minimal waste compared to other manufacturing methods, which further enhances its appeal from an environmental standpoint. By choosing to employ roll forming techniques, companies can reduce their carbon footprint and contribute to more sustainable production methods.

Conclusion

In summary, cheap roll forming aluminum offers a range of advantages that make it an attractive option for manufacturers across various sectors. Its cost-effectiveness, versatility, and minimal environmental impact cater to the demands of modern industries seeking efficiency and sustainability. As the need for high-quality, customized aluminum components continues to grow, cheap roll forming will undoubtedly play a pivotal role in shaping the future of manufacturing. Companies that embrace this innovative technique will not only benefit from significant cost savings but also position themselves as leaders in their respective markets. In an era where efficiency and sustainability are crucial, the adoption of cheap roll forming aluminum stands out as a strategy that can drive success and foster long-term growth.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025