Price of C Purlin Roll Forming Machines for Efficient Steel Construction Solutions

Understanding the Price of C Purlin Roll Forming Machines

In the world of construction and manufacturing, efficiency and precision are paramount. One of the crucial components that contribute to these efficiencies is the C purlin roll forming machine. These machines are essential for producing C purlins, which are the horizontal structural members used in buildings, bridges, and other construction applications. Given their importance, potential buyers often inquire about the cost associated with these machines. In this article, we will discuss the factors influencing the price of C purlin roll forming machines and what considerations should be taken into account when making a purchase.

What is a C Purlin Roll Forming Machine?

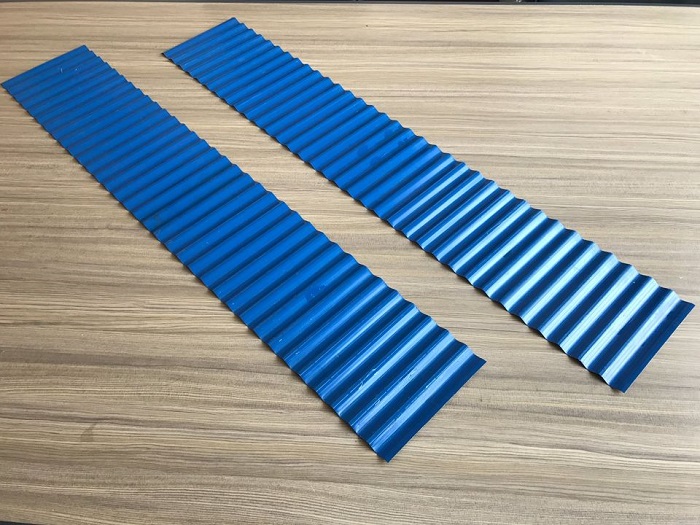

Before diving into pricing, it's crucial to understand what a C purlin roll forming machine does. This machine is designed to convert metal sheets into C-shaped purlins through a process that involves feeding metal through rollers that shape it into the desired profile. The machines can be designed for varying thicknesses and dimensions based on the specific requirements of the project. Thanks to their automated processes, they significantly enhance production efficiency, reduce labor costs, and ensure uniform quality in manufacturing.

Factors Influencing Price

1. Machine Specifications The first major factor affecting the price is the specifications of the machine itself. High-capacity machines that can produce larger quantities or handle thicker materials often come at a premium. Standard machines typically cost less, but they may not meet the production requirements for larger projects.

2. Technology and Features Modern roll forming machines often come equipped with advanced technology, such as servo motors, PLC control systems, and more. These enhancements improve efficiency and precision but also increase the cost of the equipment. Comprehensive automation features that reduce manual intervention often raise the price significantly.

3. Brand and Quality Just like any other purchase, the brand can influence the price of C purlin roll forming machines. Established manufacturers with a reputation for quality and reliability often charge more for their products. Investing in a reputable brand can lead to better long-term performance and support, which may justify the higher initial cost.

c purlin roll forming machine price

4. Customization Options Many buyers seek machines that can be tailored to specific needs. Customization may include changes in dimensions, material handling features, or additional attachments. Custom-built machines are typically more expensive than standard models.

5. Geographical Market Differences Prices can vary significantly based on geographical location. Factors like import tariffs, local manufacturing costs, and market demand all play a role in price variance across regions. In some areas, local manufacturers may offer lower prices due to reduced shipping costs and government incentives.

6. After-sales Support The level of service and support offered by the manufacturer also affects the initial cost. Comprehensive after-sales services, such as installation, training, and maintenance support, may lead to a higher upfront cost but can be worth it when considering long-term operational efficiency and machine longevity.

General Pricing Range

Generally, you can expect the price of C purlin roll forming machines to range widely, anywhere from $20,000 to $100,000 or more. High-end machines with advanced features can push the price significantly above this range. It’s essential for buyers to assess their specific requirements and budgets before making a decision.

Conclusion

Investing in a C purlin roll forming machine can be a significant financial commitment, but understanding the factors that influence price can help potential buyers make informed decisions. By analyzing their production needs, desired specifications, and the prices offered by different manufacturers, buyers can ensure they choose the right machine that fits both their operational requirements and budget. As the construction industry continues to evolve, investing in high-quality machinery is more important than ever to keep up with demand and maintain competitive advantages.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025