cheap ibr sheet roll forming machine

The Advantages of Cheap IBR Sheet Roll Forming Machines

In the rapidly evolving construction industry, the demand for durable, lightweight, and cost-effective building materials is ever-increasing. One such material that has gained significant popularity is the IBR (Inverted Box Rib) sheet, renowned for its strength and versatility. To meet the rising demand for this type of sheet, the use of roll forming machines has become essential. Among them, the cheap IBR sheet roll forming machine stands out as an efficient, cost-effective solution for manufacturers looking to produce these high-performance sheets.

Understanding IBR Sheets

IBR sheets are metal roofing sheets characterized by their unique ribbed structure, which provides additional strength and rigidity. They are widely used in both residential and commercial buildings due to their ability to withstand harsh weather conditions, ease of installation, and aesthetic appeal. These sheets can be made from various materials, including galvanized steel, pre-painted steel, and other metal alloys, contributing to their versatility in different applications.

What is a Roll Forming Machine?

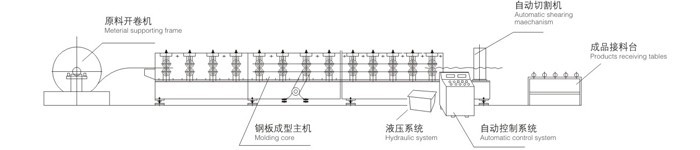

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into the desired profile through a series of calibrated rollers. A roll forming machine typically consists of a material feed system, a set of forming rollers, and a cutting mechanism. The process is highly efficient and allows for the mass production of uniform profiles, making it ideal for producing IBR sheets.

The Benefits of Cheap IBR Sheet Roll Forming Machines

1. Cost-Effectiveness The most obvious advantage of cheap IBR sheet roll forming machines is their affordability. Manufacturers, especially small to medium-sized enterprises, can invest in these machines without breaking the bank. This lower initial investment allows them to enter the market and compete effectively.

2. Increased Production Efficiency Despite being economical, these machines do not compromise on efficiency. With modern technology, cheap IBR sheet roll forming machines can produce large quantities of sheets in a short period. This high throughput means businesses can fulfill large orders quickly, enhancing overall productivity.

cheap ibr sheet roll forming machine

3. Quality and Consistency Modern roll forming machines, even the more affordable models, are engineered to produce high-quality, consistent products. Each sheet is manufactured to exact specifications, reducing waste and improving the overall quality of the final product.

4. Versatility and Customization Many cheap roll forming machines are equipped to produce various profiles, not just IBR sheets. This versatility allows manufacturers to diversify their product offerings. Furthermore, these machines can often be customized to meet specific customer demands, enabling quicker response times to market trends.

5. User-Friendly Operation Most contemporary roll forming machines come with intuitive controls and user-friendly interfaces. With proper training, even operators without extensive experience can efficiently run the machinery, simplifying the training process and reducing labor costs.

6. Durability and Low Maintenance While the price may be lower, that does not mean the quality is compromised. Cheap IBR sheet roll forming machines are typically constructed using sturdy materials that enhance durability. Furthermore, these machines require minimal maintenance, making them a sensible investment for manufacturers who aim to minimize downtime.

7. Energy Efficiency Many affordable machines are designed with energy-saving features, which can significantly reduce operational costs over time. By minimizing energy consumption, manufacturers can also contribute to environmental sustainability—a significant consideration in today's eco-conscious market.

Conclusion

The rise of cheap IBR sheet roll forming machines has revolutionized the metal forming industry, providing businesses with a cost-effective means to produce high-quality roofing sheets. With their increased efficiency, customization options, and user-friendly operation, these machines present an attractive option for manufacturers looking to expand their production capabilities without incurring substantial costs.

As demand for IBR sheets continues to grow, investing in affordable roll forming technology will position manufacturers to meet consumer needs effectively. The combination of quality, consistency, and cost-effectiveness makes cheap IBR sheet roll forming machines an invaluable asset for anyone looking to thrive in the competitive construction materials market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025