roof truss press machine factory

The Importance of Roof Truss Press Machines in Modern Construction

In the modern construction industry, efficiency and precision are paramount. One key component in the creation of roof structures is the roof truss itself. Roof trusses are triangular frameworks designed to support the roof, spanning the entire width of the building. To manufacture these essential components with the required precision and strength, roof truss press machines have become integral in factories across the globe.

What is a Roof Truss Press Machine?

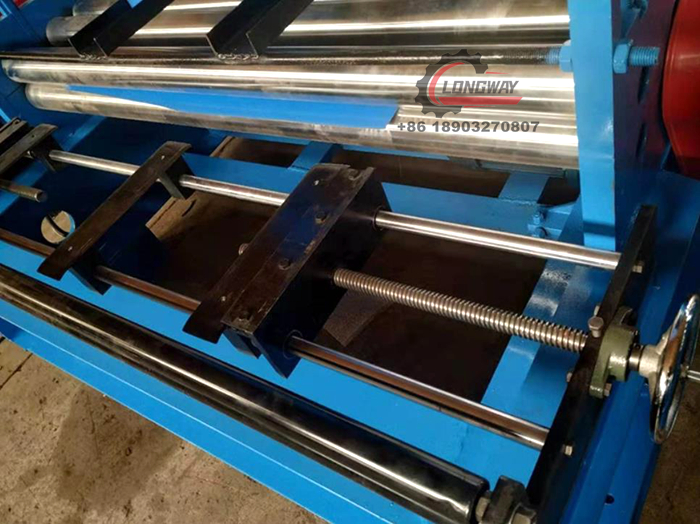

A roof truss press machine is a specialized piece of equipment used in the assembly of roof trusses. These machines employ hydraulic or mechanical pressure to join various structural elements—such as timber or metal—into a secure and stable framework. The design of these machines allows for adjustable settings to handle different sizes and types of trusses, ensuring high adaptability in production.

The primary function of a roof truss press machine is to apply consistent pressure that ensures all components are tightly bonded at joints, ultimately enhancing the structural integrity of the trusses. This is particularly important because the tightness of connections in a roof truss directly correlates to the overall strength and stability of the roof it supports.

Advantages of Using Roof Truss Press Machines

1. Increased Efficiency The automation provided by machine operations significantly reduces the time it takes to produce roof trusses. This reduction in production time allows factories to increase output, meet project deadlines, and ultimately satisfy customer demands.

2. Enhanced Precision Manual assembly of trusses can result in human error, leading to discrepancies in size and strength. Roof truss press machines are designed with precise calibrations, allowing for consistent results that meet strict engineering standards. This precision is crucial, especially when dealing with large-scale construction projects.

3. Cost-Effectiveness While the initial investment in roof truss press machines might be substantial, the long-term savings are significant. Increased production efficiency lowers labor costs and waste, while higher precision reduces the likelihood of costly structural failures down the line.

4. Versatility Modern roof truss press machines are equipped with adjustable features that allow them to work with various materials such as wood, steel, or aluminum. This versatility ensures that manufacturers can cater to a wide range of construction projects, from residential homes to large commercial buildings.

roof truss press machine factory

5. Improved Safety By automating the truss assembly process, the risk associated with manual handling and traditional building methods is significantly reduced. Workers are less exposed to potential injuries related to lifting heavy materials and operating dangerous tools.

Impact on the Construction Industry

The advent of roof truss press machines has revolutionized how roof structures are manufactured. With advancements in technology, these machines integrate sophisticated features like computer-aided design (CAD) systems, allowing for seamless integration of design and production. This technological evolution contributes to smarter manufacturing processes, greater alignment with industry standards, and compliance with safety regulations.

Moreover, the durability and reliability of roof trusses made with press machines have a direct impact on the longevity of buildings. As more architects and builders recognize the advantages of using roof truss press machines, the construction industry is shifting towards these methods to build stronger, more reliable properties.

The Future of Roof Truss Manufacturing

As the construction industry continues to evolve, so too will the technologies used to manufacture structural components. Innovations in automation and artificial intelligence will likely lead to even greater efficiencies in roof truss production. The integration of smart technology could enable machines to self-calibrate and monitor the quality of trusses in real time, ensuring that every produced unit meets rigorous standards.

Additionally, as sustainability becomes a focal point in construction practices, the utilization of roof truss press machines can facilitate the use of eco-friendly materials, further enhancing the industry's commitment to reducing its carbon footprint.

Conclusion

The roof truss press machine factory is more than just a place of manufacturing; it represents a significant leap towards modernization in the construction industry. By prioritizing efficiency, precision, and safety, these machines play a pivotal role in creating reliable structures that can endure the test of time. As technology advances, the capabilities of roof truss press machines will expand even further, ensuring that they remain a cornerstone of construction for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025