Cost-effective Cut-to-Length and Slitting Line for Efficient Metal Processing

Understanding Cheap Cut to Length and Slitting Lines Technology for Efficiency

In the realm of metal processing, efficiency and cost-effectiveness are key concerns for manufacturers and fabricators. One technology that has gained exceptional traction in recent years is the cut to length and slitting line. Specifically designed to handle steel and other sheet materials, these lines can dramatically enhance productivity while minimizing waste, making them an invaluable asset in industrial settings.

What is a Cut to Length and Slitting Line?

A cut to length and slitting line is a sophisticated piece of machinery that is used to trim large coils of material into more manageable lengths or strips. The process begins with unwinding the coil, which is then either cut into specific lengths or slitted into narrower strips. This dual capability allows manufacturers to quickly produce products tailored to their specific requirements, whether that's sheets for construction or narrower pieces for automotive applications.

How Does It Work?

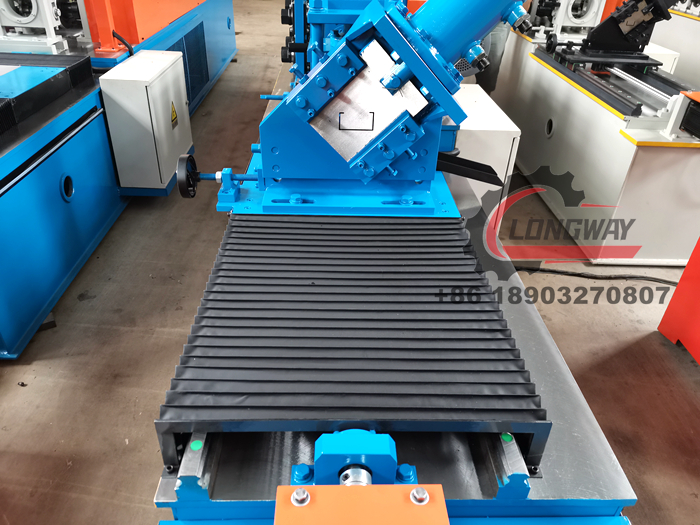

The operation of a cut to length and slitting line comprises several key components an uncoiler, a slitting section, a cut-to-length section, and a recoiler. The uncoiler feeds in the metal coil, and as it unwinds, the slitting section utilizes circular blades to cut the coil into the desired widths. Next, the cut-to-length section measures and slices the material to the needed lengths, often employing a precision shearing mechanism.

Once the material has been processed, it can be either stacked for further use or recoiled for storage. Advanced automation and control systems frequently accompany these setups, allowing for quick adjustments in size and speed, which enhances overall productivity.

Advantages of Cut to Length and Slitting Lines

cheap cut to length and slitting line

1. Cost Efficiency One of the chief benefits of using a cut to length and slitting line is the reduction in material waste. By precisely cutting material to required dimensions, manufacturers can utilize nearly the entire coil, leading to significant cost savings.

2. Time-saving The automated aspects of these lines facilitate quicker production times. Operators can program the machinery to produce different lengths and widths without extensive downtime, making rapid adjustments more feasible than ever.

3. Versatility Modern cut to length and slitting lines can handle various types of metals, including aluminum, stainless steel, and carbon steel. This versatility makes them an attractive option for a broad range of industries.

4. High Precision The accuracy of cuts and slits provided by advanced machinery ensures that the final product meets tight tolerances. This precision is essential for applications where exact dimensions are critical.

5. Scalability These lines can be adapted for various production scales. Whether a small shop needs to handle custom orders or a large factory requires high-volume production, cut to length and slitting lines can be tailored to meet specific demands.

Conclusion

As the demand for efficient metal processing continues to rise, cut to length and slitting lines stand out as a superior solution. Offering a perfect blend of cost savings, increased production speed, precision, and versatility, they have become a staple in manufacturing and industrial applications. By investing in such technology, businesses can stay competitive in an increasingly demanding market, ensuring they can deliver quality products tailored to their clients’ needs.

In summary, understanding and implementing cut to length and slitting lines can revolutionize manufacturing processes, ultimately leading to enhanced productivity and profitability in various sectors. As technology continues to advance, these systems will likely evolve, presenting even more opportunities for efficiency in metal processing operations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025