Affordable IBR Sheet Production Machine Price for Your Business Needs

Exploring the Cost of Cheap IBR Sheet Making Machines

In the world of construction and industrial manufacturing, the demand for efficient and economical production processes is ever-increasing. One of the key products that have gained significant importance in recent years is the IBR (Inverted Box Rib) sheet. These sheets are widely used in roofing and wall cladding due to their durability and aesthetic appeal. As the need for IBR sheets rises, so does the interest in machines that can manufacture them. This article delves into the price factors associated with cheap IBR sheet making machines, their significance, and what to consider when investing in such equipment.

Understanding IBR Sheet Making Machines

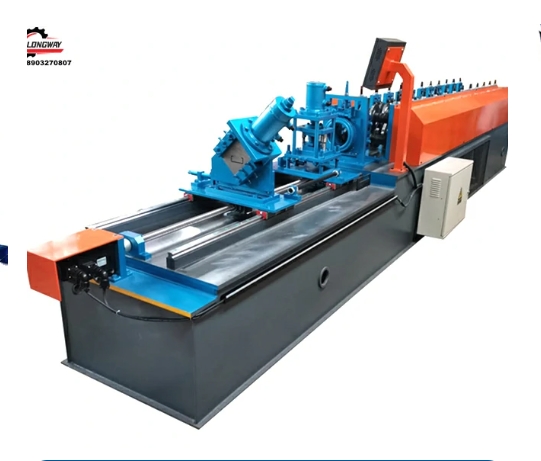

IBR sheet making machines are specialized equipment designed to manufacture IBR sheets from raw materials. The sheets are typically made from metal, including galvanized steel or aluminum, which provides the strength and longevity required for various applications. The manufacturing process involves bending and shaping the raw material into specific profiles, enabling the production of high-quality sheets efficiently.

Price Variability in IBR Sheet Making Machines

The prices of IBR sheet making machines can vary widely, influenced by several factors. Typically, cheaper models might range from a few thousand to tens of thousands of dollars, depending on specifications and features. Here are some critical aspects that affect pricing

1. Material Quality The type of materials used to construct the machine impacts the price. Machines made from high-quality steel components are likely to cost more but will offer better durability and performance.

2. Production Capacity The output capacity of the machine—how many sheets it can produce per hour—plays a significant role in determining its price. Higher capacity machines that can handle larger volumes generally come with a higher price tag.

3. Automation Level Fully automated machines, equipped with advanced technology for minimal human intervention, often cost more than manual or semi-automated models. However, the investment can lead to long-term savings through increased efficiency and reduced labor costs.

4. Customization Options Machines that offer customizable features to produce different profiles or sizes of IBR sheets may be priced higher. These features allow manufacturers to cater to specific client requirements, making them a valuable asset.

5. Brand Reputation Well-known brands may charge a premium for their equipment due to their proven reliability and after-sale service. On the other hand, lesser-known manufacturers might offer cheaper alternatives that require careful consideration of quality and support.

Benefits of Investing in Affordable IBR Sheet Making Machines

cheap ibr sheet making machine price

Opting for cheaper IBR sheet making machines can provide several benefits, especially for small to medium-sized enterprises

1. Lower Initial Investment A lower purchase price means that businesses can allocate resources to other essential areas, such as marketing or workforce development.

2. Opportunity to Enter the Market For startups and emerging businesses, affordable machines provide an entry point into the market without the burden of hefty financial commitments.

3. Flexibility With lower-cost machines, companies can test different market segments or production techniques without a substantial risk of financial loss.

4. Scalability As businesses grow, they can invest in more advanced machinery later, allowing for a flexible and gradual expansion strategy.

Considerations Before Purchase

While the price is a significant factor, it's crucial not to compromise on quality and functionality. Here are some considerations before purchasing

- Research Look for reviews and testimonials from previous customers to gauge the reliability and performance of the machine.

- After-Sales Support Ensure the manufacturer provides sufficient support for installation, maintenance, and repairs.

- Trial Runs If possible, conduct trial runs to assess the machine's performance before making a final decision.

In conclusion, while there are many options for cheap IBR sheet making machines, it is essential to weigh price against quality and functionality. By conducting thorough research and considering various factors such as production capacity and material quality, businesses can make informed decisions that cater to their operational needs and budget constraints. The right investment in machinery not only maximizes efficiency but also positions companies for growth in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025