Jan . 24, 2025 01:32

Back to list

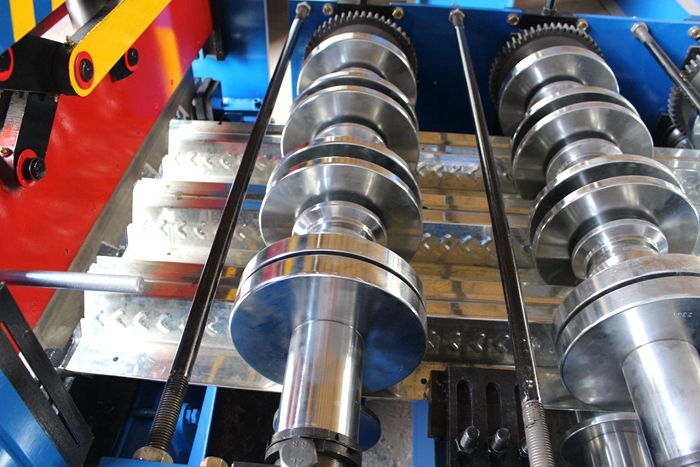

c channel rolling machine

Navigating the intricate landscape of metal fabrication, the C channel rolling machine stands out as a cornerstone of precision engineering. These machines are pivotal in transforming robust metal sheets into meticulously crafted C-shaped profiles, serving a versatile range of industries from construction to automotive manufacturing.

Purchasing decisions related to C channel rolling machines should be informed by comprehensive expertise. Prospective buyers must consider factors such as machine size, roll capacity, and material compatibility. Moreover, seeking manufacturers with a proven track record of producing reliable machinery, and providing robust after-sales support can greatly enhance one's investment and operational outcomes. In the realm of trustworthiness, the rise of digital platforms has ushered in a wealth of user-generated content offering firsthand experiences with C channel rolling machines. These online reviews and testimonials can provide valuable insights into the machine’s performance, reliability, and the quality of customer service offered by manufacturers. A consistent pattern of positive feedback often signals a trustworthy product. An authoritative stance in this domain is reinforced by engaging with industry certifications and standards. Machines adhering to stringent international standards such as ISO or CE offer assurance of quality and safety, marking them as superior choices in the marketplace. Manufacturers who align their products with such benchmarks often gain a competitive edge, demonstrating a commitment to excellence. In conclusion, the world of C channel rolling machines is a testament to the fusion of engineering prowess and operational intelligence. By prioritizing expertise, authoritativeness, and trustworthiness in every aspect of the machine's lifecycle—from design to operation—manufacturers and operators can achieve remarkable outcomes. This dedication not only ensures the production of high-quality C channels but also fortifies the reputations of those who choose to invest in these technological marvels.

Purchasing decisions related to C channel rolling machines should be informed by comprehensive expertise. Prospective buyers must consider factors such as machine size, roll capacity, and material compatibility. Moreover, seeking manufacturers with a proven track record of producing reliable machinery, and providing robust after-sales support can greatly enhance one's investment and operational outcomes. In the realm of trustworthiness, the rise of digital platforms has ushered in a wealth of user-generated content offering firsthand experiences with C channel rolling machines. These online reviews and testimonials can provide valuable insights into the machine’s performance, reliability, and the quality of customer service offered by manufacturers. A consistent pattern of positive feedback often signals a trustworthy product. An authoritative stance in this domain is reinforced by engaging with industry certifications and standards. Machines adhering to stringent international standards such as ISO or CE offer assurance of quality and safety, marking them as superior choices in the marketplace. Manufacturers who align their products with such benchmarks often gain a competitive edge, demonstrating a commitment to excellence. In conclusion, the world of C channel rolling machines is a testament to the fusion of engineering prowess and operational intelligence. By prioritizing expertise, authoritativeness, and trustworthiness in every aspect of the machine's lifecycle—from design to operation—manufacturers and operators can achieve remarkable outcomes. This dedication not only ensures the production of high-quality C channels but also fortifies the reputations of those who choose to invest in these technological marvels.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products