C Channel Roll Forming Machine Manufacturer for Reliable Export Solutions

C Channel Roll Forming Machine Exporter Revolutionizing the Manufacturing Industry

In today’s manufacturing landscape, efficiency and precision play critical roles in production processes. The increasing demand for high-quality metal products has led to a rise in specialized machinery, among which the C channel roll forming machine stands out. Exporters of these machines are contributing significantly to various industries by providing advanced solutions that enhance productivity and reduce operational costs.

Understanding C Channel Roll Forming

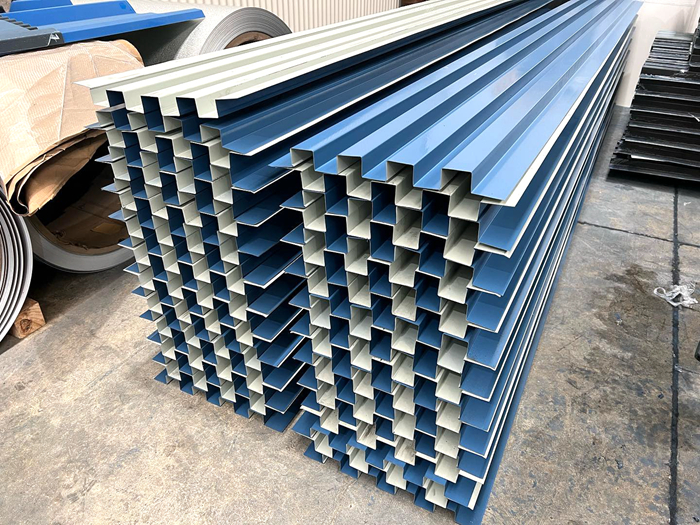

C channel roll forming machines are designed to produce C-shaped steel channels used in various applications, including construction, automotive, and manufacturing. The process involves feeding a continuous strip of metal into a series of rollers, which progressively shape the material into a C-channel profile. This technology not only ensures uniformity and precision in the final product but also allows for high-speed production, which is vital for meeting the growing demands of different sectors.

Why Choose C Channel Roll Forming Machines?

One of the primary reasons for the popularity of C channel roll forming machines is their ability to produce multiple channels in various sizes and thicknesses from the same machine. This versatility allows manufacturers to cater to diverse customer requirements without the need for extensive additional machinery. Moreover, the machines are designed for durability and longevity, making them a worthwhile investment for businesses aiming to optimize their production lines.

Benefits of Importing C Channel Roll Forming Machines

When it comes to sourcing C channel roll forming machines, many companies choose to import them from specialized exporters. This strategy offers several advantages

1. Advanced Technology Exporters often utilize cutting-edge technology in their machines, ensuring enhanced performance, precision, and efficiency. This technological edge helps manufacturers maintain competitive advantages in their respective markets.

2. Cost-Effective Solutions Sourcing directly from exporters can often be more cost-effective than local procurement. Importing allows companies to benefit from lower production costs and competitive pricing structures offered by manufacturers in countries where such machinery is produced at scale.

c channel roll forming machine exporter

3. Customized Solutions Many exporters provide customization options tailored to specific production needs of clients. This adaptability ensures businesses can achieve optimized production setups that align perfectly with their operational processes.

4. Access to Global Markets Utilizing equipment from international exporters allows manufacturers to tap into global standards of quality and manufacturing practices. This exposure can lead to improved product quality and greater market acceptance.

5. Training and Support Reputable exporters often provide maintenance and training services to ensure that clients can maximize the potential of their machines. This level of support can alleviate concerns relating to operational efficiency and machine reliability.

Challenges in the Export Market

Despite the numerous benefits, exporting C channel roll forming machines does come with its challenges. Different countries have specific regulations and standards that can complicate the export process. Compliance with local laws, tariffs, and shipping logistics can pose hurdles for exporters and importers alike. However, with the right strategies and partners, these challenges can be navigated successfully.

Future Trends in Roll Forming Technology

The future of C channel roll forming machines looks promising, with ongoing advancements in automation, artificial intelligence (AI), and Industry 4.0 practices. Smart machines equipped with sensors and data analytics will enhance real-time monitoring and predictive maintenance, further boosting efficiency and reducing downtime. As manufacturers increasingly adopt these technologies, the demand for high-quality C channel roll forming machines is likely to grow, providing a lucrative avenue for exporters.

Conclusion

As the manufacturing sector continues to evolve, the importance of innovative machinery such as C channel roll forming machines cannot be overstated. Exporters play a crucial role in supplying these essential tools, driving efficiency and quality across various industries. By choosing the right partner for sourcing these machines, manufacturers can effectively meet market demands, enhance production capabilities, and thrive in an ever-competitive environment. Consequently, investing in high-quality C channel roll forming machines stands as a significant step towards achieving operational excellence and long-term success in the manufacturing arena.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025