roll former manufacturers companies

The Roll Former Manufacturers A Vital Sector in Modern Manufacturing

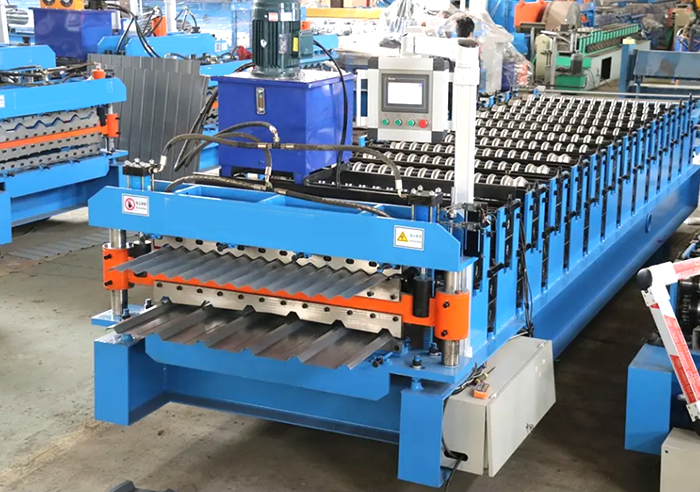

The roll forming process is a crucial method of manufacturing that involves shaping metal into a desired profile by passing it through a series of rollers. This process is widely used in various industries, including automotive, construction, and appliance manufacturing. Roll former manufacturers are essential players in this field, providing the necessary equipment and expertise to create high-quality metal components.

What is Roll Forming?

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is fed through sets of rolls to form it into a specific shape. This shape can range from simple angles to complex profiles that meet various industry standards. The process is highly efficient and is characterized by its ability to produce high volumes of consistent and precise components. The finished products are integral in the construction of buildings, infrastructure, and machinery, making the role of roll former manufacturers critical in the supply chain.

Importance of Roll Former Manufacturers

Roll former manufacturers design and produce the machinery required for the roll forming process. These companies play a pivotal role in modern manufacturing by offering a variety of solutions tailored to their customers' needs. A well-designed roll forming machine can significantly enhance production efficiency, reduce waste, and minimize operational costs. The capabilities of these machines vary widely; some manufacturers offer standard models, while others specialize in custom designs to meet specific client requirements.

In addition to equipment production, these manufacturers also provide essential services such as maintenance, repair, and technical support. This comprehensive approach ensures that clients can operate their machinery effectively and minimize downtime, which is crucial for maintaining productivity in a manufacturing environment.

Market Trends and Innovations

roll former manufacturers companies

The market for roll former manufacturers has evolved significantly in recent years, driven by advancements in technology and the growing demand for specialized metal components. As industries continue to seek higher efficiency and lower costs, manufacturers are embracing innovations such as automation, digitalization, and the integration of Industry 4.0 principles.

Automation in roll forming has led to increased production speeds and enhanced precision. Manufacturers are increasingly incorporating robotics and advanced control systems in their machines, allowing for real-time monitoring and adjustments during the manufacturing process. This technological shift not only improves product quality but also reduces labor costs, making it an attractive option for businesses looking to optimize their operations.

Furthermore, the demand for customized solutions is on the rise. Industries require unique shapes and profiles that can not only meet functional requirements but also align with aesthetic standards. Roll former manufacturers are adapting by investing in research and development to offer innovative machinery capable of creating complex shapes with ease.

Challenges Facing Roll Former Manufacturers

Despite the growth potential in this sector, roll former manufacturers face several challenges. The competition is fierce, with many companies vying for market share. To remain competitive, manufacturers must continually innovate and differentiate their products and services from those of their competitors.

Additionally, fluctuations in raw material prices and supply chain disruptions can impact production costs and timelines. Manufacturers must remain agile and resilient to navigate these challenges, ensuring that they can deliver quality products to their clients on time and within budget.

Conclusion

In conclusion, roll former manufacturers are a vital component of the modern manufacturing landscape. Their ability to provide customized solutions, innovative machinery, and essential support services makes them indispensable to various industries. As technology continues to evolve, these manufacturers will need to adapt to changing market demands while overcoming contemporary challenges. The future of roll forming lies in the hands of these manufacturers, who will shape not only metal but also the next generation of manufacturing processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025