Automated 18 Corrugated Steel Roofing Sheet Making Machine

Understanding the Significance of the Corrugated Steel Roofing Sheet Making Machine in Modern Construction

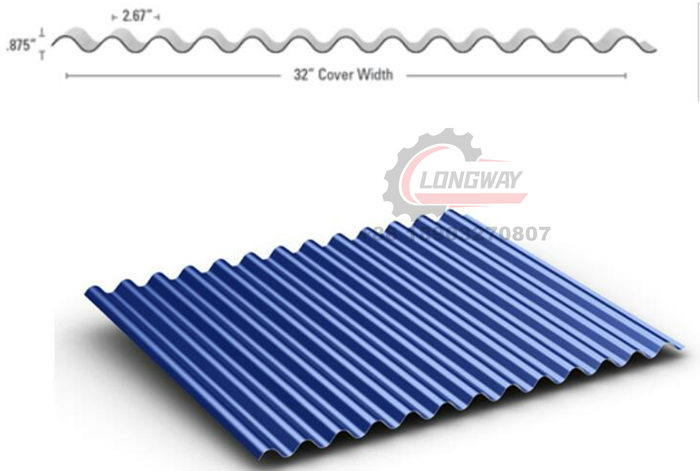

The demand for robust, cost-effective, and aesthetically pleasing roofing solutions continues to drive innovation in the construction industry. At the heart of this evolution lies the 18 Corrugated Steel Roofing Sheet Making Machine. This specialized equipment is pivotal for manufacturers seeking to produce high-quality corrugated steel sheets efficiently and consistently. These machines are essential for meeting the growing needs of residential, commercial, and industrial projects worldwide, where durability, ease of installation, and weather resistance are paramount for the building envelope.

Industry trends indicate a significant shift towards automated and high-precision machinery. The global roofing market, valued at over USD 100 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030, with metal roofing commanding a substantial share due to its longevity and recyclability. This growth trajectory underscores the critical role of advanced roll forming technology. Our machines are engineered to align with these trends, offering superior production capabilities that reduce labor costs, minimize material waste, and enhance overall operational efficiency, thereby providing a competitive edge in a dynamic market.

The robust design and intelligent control systems integrated into modern corrugated sheet machines ensure exceptional output quality, meeting stringent international standards. This allows for the swift fabrication of roofing sheets suitable for diverse climates and structural requirements, from lightweight residential sheds to large-span industrial buildings. Furthermore, the ability to customize profiles and dimensions directly impacts project flexibility and material optimization, making the investment in a state-of-the-art 18 Corrugated Steel Roofing Sheet Making Machine a strategic imperative for any forward-thinking construction material supplier.

The Advanced Manufacturing Process of an 18 Corrugated Steel Roofing Sheet Making Machine

Manufacturing an 18 Corrugated Steel Roofing Sheet Making Machine involves a sophisticated multi-stage process, ensuring the final product meets the highest benchmarks for precision, durability, and operational efficiency. The primary material for the machine's robust frame is typically high-grade structural steel, often Q235 or Q345, which provides the necessary rigidity and stability for continuous, heavy-duty operation. For critical components like the forming rollers, specialized alloy steels such as GCr15 or Cr12MoV are employed. These materials are selected for their exceptional hardness, wear resistance, and ability to maintain dimensional stability under high stress, directly contributing to the longevity and consistent performance of the machine.

The manufacturing process begins with precise cutting and welding of the main frame components. This is followed by critical machining operations, where CNC (Computer Numerical Control) technology plays a vital role. CNC machining ensures the exact geometry and surface finish of the forming rollers, which are the heart of the roll forming process. After machining, rollers undergo a rigorous heat treatment process, typically quenching and tempering, to achieve the required hardness (e.g., HRC58-62 for GCr15 steel) and toughness, significantly extending their service life and ensuring the consistent quality of the corrugated sheets. Bearing housings and other precision parts are also manufactured using advanced machining techniques to achieve tight tolerances.

Precision engineering for the 18 Corrugated Steel Roofing Sheet Making Machine's core components.

Every component undergoes stringent quality control at various stages. Key inspection standards include ISO 9001 for quality management systems, ensuring process consistency, and ANSI standards for specific mechanical tolerances and material properties. Dimensional accuracy of rollers, hardness testing of treated parts, and comprehensive functional testing of the complete machine assembly are routine. The typical service life of a well-maintained 18 Corrugated Steel Roofing Sheet Making Machine can exceed 15-20 years, a testament to the quality of its materials and manufacturing processes. These machines are broadly applicable across various construction-related sectors, including civil engineering, industrial building construction, and prefabricated housing, providing energy-efficient and corrosion-resistant roofing solutions through the high-quality sheets they produce.

Key Technical Parameters and Performance Metrics

A thorough understanding of the technical specifications is crucial for any potential investor in an 18 Corrugated Steel Roofing Sheet Making Machine. These parameters dictate the machine's capability, efficiency, and the quality of the final product. Key specifications often include the decoiler capacity, typically ranging from 5 to 10 tons, which determines the maximum coil weight the machine can handle. The forming speed, expressed in meters per minute (m/min), directly impacts production throughput; advanced machines can achieve speeds of 20-30 m/min, enabling high-volume output. Roll stations, usually between 16 and 22 groups, define the number of passes required to form the profile, influencing precision and minimizing material stress.

Intuitive PLC control system for the 18 Corrugated Steel Roofing Sheet Making Machine.

The main motor power, often 7.5kW to 11kW, provides the necessary drive for the entire roll forming process. Essential to precision cutting is the hydraulic station power, typically 5.5kW, which ensures clean and accurate cuts. The material thickness range, commonly 0.3-0.8mm for galvanized or color-coated steel, dictates the versatility of the machine for various applications. Our 18 Corrugated Steel Roofing Sheet Making Machine models are equipped with advanced PLC (Programmable Logic Controller) control systems, such as Siemens or Panasonic, ensuring fully automated operation, precise length cutting, and easy profile changes. This level of automation significantly reduces manual intervention and potential errors, leading to higher efficiency and superior product consistency.

Typical Specifications for an 18 Corrugated Steel Roofing Sheet Making Machine

| Parameter | Value/Description |

|---|---|

| Suitable Raw Material | PPGI, Galvanized Steel, Aluminum Coil |

| Material Thickness Range | 0.3 mm - 0.8 mm |

| Feeding Width | 914 mm - 1250 mm (adjustable) |

| Forming Speed | 15-25 m/min (adjustable) |

| Roll Stations | 18-20 groups |

| Roller Material | High-grade GCr15 steel with Chrome plating |

| Main Motor Power | 7.5 kW - 11 kW |

| Hydraulic Station Power | 5.5 kW |

| Control System | PLC (e.g., Siemens/Panasonic) with Touch Screen |

| Decoiler Capacity | 5-10 Ton passive or hydraulic |

| Machine Weight | Approx. 8-12 Ton |

The integration of advanced sensors and real-time monitoring capabilities further enhances the machine's reliability. Operators can monitor production statistics, error logs, and machine status directly from the touch screen interface, enabling quick diagnostics and adjustments. This level of technical sophistication ensures that the 18 Corrugated Steel Roofing Sheet Making Machine not only meets but often exceeds the performance expectations of demanding industrial environments, delivering superior precision and efficiency for every sheet produced.

Application Scenarios and Strategic Advantages

The versatility of the 18 Corrugated Steel Roofing Sheet Making Machine makes it an indispensable asset across a wide array of application scenarios within the construction and manufacturing industries. Its primary use lies in producing corrugated steel sheets for roofing and wall cladding for various building types. This includes large-scale industrial warehouses, agricultural facilities like barns and sheds, commercial buildings, and even residential housing in regions where steel roofing is prevalent due to its durability and weather resistance. The machine's ability to process different gauges of steel, including pre-painted galvanized iron (PPGI), galvanized steel, and aluminum, broadens its utility and market reach.

Beyond general construction, these machines are critical for infrastructure projects requiring robust and long-lasting material. For instance, in disaster-prone areas, quick and efficient production of roofing sheets is vital for reconstruction efforts. The high forming speed and automated cutting ensure rapid output, enabling timely supply of materials for urgent projects. The sheets produced offer significant advantages such as excellent anti-corrosion properties (especially when using galvanized or coated steel), superior load-bearing capacity, and inherent fire resistance, making them ideal for challenging environments. Furthermore, the precise formation by the machine minimizes material waste, contributing to cost savings and environmental sustainability.

The 18 Corrugated Steel Roofing Sheet Making Machine delivers high-quality output for various applications.

A core technical advantage of our 18 Corrugated Steel Roofing Sheet Making Machine lies in its robust roller design and intelligent software, which allow for consistent and uniform corrugations, crucial for structural integrity and water drainage. This precision minimizes future maintenance for end-users, enhancing the reputation of the material supplier. Moreover, the ability to produce large volumes of sheets with minimal human intervention provides a significant operational advantage, particularly for companies looking to scale their production or enter new markets. The machine's energy-efficient operation also contributes to lower operating costs, making it a sound long-term investment.

Choosing Your Supplier: A Manufacturer Comparison

Selecting the right manufacturer for an 18 Corrugated Steel Roofing Sheet Making Machine is a critical decision that impacts long-term operational success and return on investment. While many suppliers exist in the market, discerning between them requires a careful evaluation of several factors beyond just the initial price point. Key differentiators include the quality of materials used in machine construction, the sophistication of the control system, after-sales support, and the manufacturer's track record and reputation. Companies with extensive experience and a focus on research and development often provide more reliable and technologically advanced solutions.

For instance, some manufacturers may offer machines with basic manual controls, leading to higher labor costs and potential inconsistencies in output. In contrast, leading providers integrate advanced PLC systems (e.g., Siemens, Mitsubishi) with user-friendly touchscreens, enabling fully automated production, precise length cutting, and remote diagnostics capabilities. The quality of forming rollers is another significant factor; premium manufacturers utilize CNC-machined GCr15 or Cr12MoV steel with hard chrome plating, ensuring prolonged life and superior sheet finish, whereas lesser quality rollers wear quickly, leading to costly downtime and inconsistent product quality.

| Feature/Criterion | Leading Manufacturer (e.g., Our Standard) | Typical Budget Option |

|---|---|---|

| Control System | Siemens/Panasonic PLC with Touch Screen & Remote Support | Basic PLC or Manual Controls |

| Roller Material & Treatment | GCr15/Cr12MoV, CNC Machined, Quenched & Tempered, Hard Chrome Plated (HRC 58-62) | 45# Steel, Basic Heat Treatment, No Plating |

| Frame Construction | Robust Welded Q345/Q235 Steel, Annealed for Stress Relief | Lighter Welded Steel, Potential for Vibration |

| Production Speed & Accuracy | High (20-25 m/min), ±1mm length accuracy | Moderate (10-15 m/min), ±2-3mm length accuracy |

| Warranty & Support | 2-year full warranty, Lifetime Technical Support, On-site Installation/Training | 1-year limited warranty, Online Support Only |

Our commitment to quality is reflected in our ISO 9001 certification and extensive experience, serving clients globally for over 15 years. We ensure every 18 Corrugated Steel Roofing Sheet Making Machine is built to last, offering unparalleled performance and reliability. Choosing a reputable partner like us ensures not only a superior machine but also comprehensive support throughout its operational lifespan, maximizing your investment's value.

Customization Solutions and Real-World Application Cases

Recognizing that every business has unique production requirements, we offer extensive customization options for our 18 Corrugated Steel Roofing Sheet Making Machine. This flexibility ensures that the machine perfectly aligns with specific material types, desired sheet profiles, production capacities, and integration needs within existing factory setups. Customization can include adjustments to the material thickness range, the number of roll forming stations for more complex profiles, the integration of pre-punching or embossing capabilities, and tailored automation levels. For instance, clients requiring very high output might opt for a higher-speed main motor and a fully automated stacking system to streamline the entire production line.

A recent application case involved a client in Southeast Asia who needed to produce corrugated sheets for large-scale agricultural infrastructure projects. Their specific requirement was for a machine capable of handling wider coils (up to 1250mm) and producing sheets with a non-standard wave height for improved water runoff in heavy rain conditions. Our engineering team designed a custom roller profile and adjusted the machine's frame width and control software to accommodate these specifications. The result was a tailored 18 Corrugated Steel Roofing Sheet Making Machine that met their unique regional demands and significantly boosted their production efficiency, delivering sheets perfectly suited for their local market.

The robust frame and precise mechanics of the 18 Corrugated Steel Roofing Sheet Making Machine.

Another case involved a European construction firm seeking to integrate an 18 Corrugated Steel Roofing Sheet Making Machine into a fully automated production line for modular housing components. This necessitated seamless integration with their existing ERP system and strict adherence to European safety standards (CE certification). We provided a machine with a custom communication interface and ensured all safety features, including light curtains and emergency stops, met the required directives. This tailored approach not only delivered a high-performance machine but also optimized their overall manufacturing workflow, proving our capability in providing comprehensive, client-centric solutions that extend beyond standard product offerings. Our engineers collaborate closely with clients to transform specific needs into tangible, high-performing machine solutions.

Trustworthiness: FAQs, Delivery, Warranty, and Support

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for an 18 Corrugated Steel Roofing Sheet Making Machine?

A1: Standard models typically have a lead time of 30-45 working days from order confirmation. Custom configurations may require 50-70 working days due to specialized design and manufacturing processes.

Q2: What kind of steel coils can this machine process?

A2: Our 18 Corrugated Steel Roofing Sheet Making Machine is designed to process various steel types, including pre-painted galvanized iron (PPGI), galvanized steel, and aluminum coils, with optimal performance within the 0.3mm to 0.8mm thickness range.

Q3: Is on-site installation and training provided?

A3: Yes, we offer comprehensive on-site installation and training services globally. Our experienced technicians will guide your team through machine operation, maintenance, and troubleshooting, ensuring a smooth transition to full production. Travel and accommodation expenses are typically borne by the client.

Q4: What are the power requirements for the machine?

A4: The power requirements vary slightly depending on the specific model and customization. Generally, our machines require 380V/50Hz/3-phase or 480V/60Hz/3-phase power supply. Detailed electrical specifications will be provided in the technical documentation.

Delivery, Warranty, and Customer Support

We pride ourselves on our streamlined delivery process and robust after-sales support. Each 18 Corrugated Steel Roofing Sheet Making Machine is carefully packaged and shipped to ensure safe arrival at your facility, with global logistics partners facilitating efficient transport. Our standard warranty covers two years for mechanical components and one year for electrical parts, providing peace of mind and protection for your investment. This warranty reflects our confidence in the quality and durability of our machinery, built to exacting ISO 9001 standards.

Beyond the warranty period, we offer lifetime technical support. Our dedicated support team is available via phone, email, and remote diagnostics to assist with any operational queries or technical issues. We maintain a comprehensive inventory of spare parts, ensuring prompt delivery for any necessary replacements, minimizing potential downtime. Our commitment to client satisfaction extends throughout the entire lifecycle of your 18 Corrugated Steel Roofing Sheet Making Machine, reinforcing our position as a trusted partner in the industry.

References

- Grand View Research. (2023). Roofing Market Size, Share & Trends Analysis Report, 2023-2030.

- International Organization for Standardization. (2020). ISO 9001:2015 Quality management systems — Requirements.

- Metal Construction Association. (2022). Life Cycle Assessment of Metal Roofing Systems.

- Steel Construction Institute. (2021). Design Guide for Cold Formed Steel Sections.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025