Jan . 10, 2025 08:47

Back to list

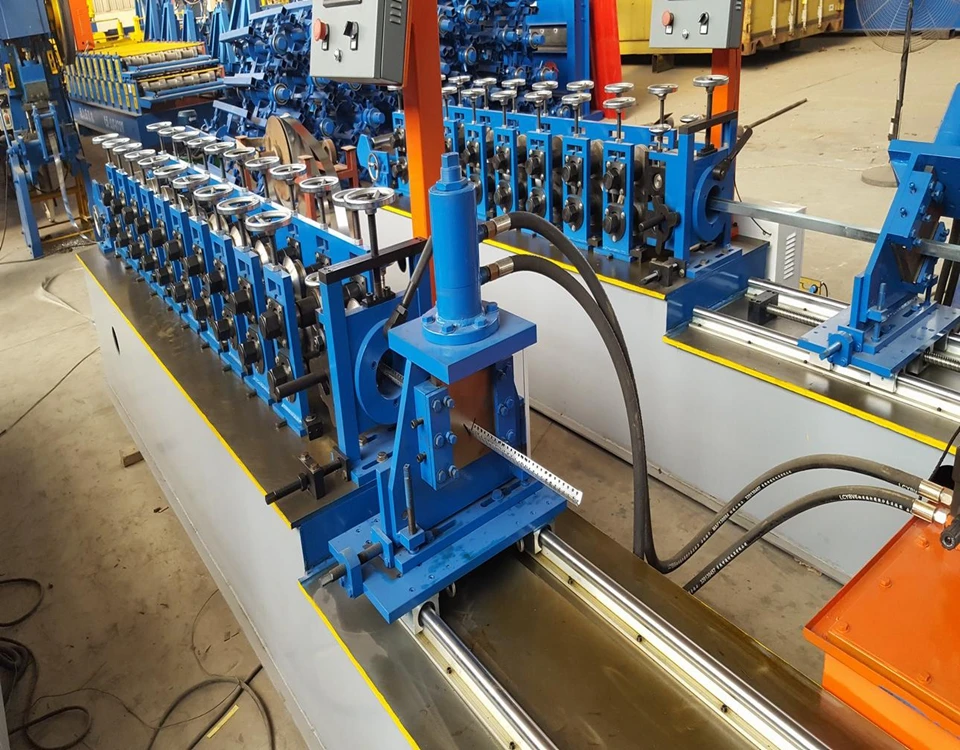

angle roll forming machine

In the cutting-edge realm of metal fabrication, angle roll forming machines are emerging as indispensable tools, offering a level of precision and efficiency that is reshaping industrial production. With decades of collective experience from engineers and operators, the current generation of angle roll forming machines stands as a testament to technological advancement and practical application.

When discussing the authority of angle roll forming machines in the metal fabrication industry, one must acknowledge the significant influence these machines have on production standards. As industry benchmarks evolve, machines like these set the pace, offering capabilities that allow manufacturers to adhere to stricter tolerances and achieve higher quality standards across a range of products. Their ability to produce complex profiles with a high degree of accuracy makes them essential in sectors such as automotive, aerospace, and construction. The trustworthiness of angle roll forming machines is established through a combination of their operational performance and the reputation of the manufacturers. Leading machine manufacturers provide extensive support networks that include technical assistance, regular maintenance services, and user training programs. This comprehensive support ensures customer trust, knowing that their investment in such technology is backed by professional support and continuous improvement strategies. In conclusion, angle roll forming machines are not just tools; they are pivotal components of modern manufacturing infrastructure that embody Experience through seasoned operators, Expertise via specialized engineering, Authoritativeness by setting industry standards, and Trustworthiness via dependable performance and manufacturer support. Embracing the use of these machines means embracing the future of efficient, high-quality production.

When discussing the authority of angle roll forming machines in the metal fabrication industry, one must acknowledge the significant influence these machines have on production standards. As industry benchmarks evolve, machines like these set the pace, offering capabilities that allow manufacturers to adhere to stricter tolerances and achieve higher quality standards across a range of products. Their ability to produce complex profiles with a high degree of accuracy makes them essential in sectors such as automotive, aerospace, and construction. The trustworthiness of angle roll forming machines is established through a combination of their operational performance and the reputation of the manufacturers. Leading machine manufacturers provide extensive support networks that include technical assistance, regular maintenance services, and user training programs. This comprehensive support ensures customer trust, knowing that their investment in such technology is backed by professional support and continuous improvement strategies. In conclusion, angle roll forming machines are not just tools; they are pivotal components of modern manufacturing infrastructure that embody Experience through seasoned operators, Expertise via specialized engineering, Authoritativeness by setting industry standards, and Trustworthiness via dependable performance and manufacturer support. Embracing the use of these machines means embracing the future of efficient, high-quality production.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products