Africa 686 IBR Roof Sheet Making Machine - High Efficiency Output

The Africa 686 IBR roof sheet making machine stands as a flagship solution in the industrial roof cladding sector. Designed for high product accuracy, longevity, energy efficiency, and compatibility with international standards like ISO and ANSI, this advanced roll forming equipment is reshaping manufacturing trends across Africa and beyond.

1. Market & Industry Trends for IBR Roof Sheet Manufacturing in Africa

IBR (Inverted Box Rib) roof sheets are a staple in African construction, valued for cost efficiency, rapid installation, and corrosion resistance. Market data from 2023 indicates a 16% YoY increase in IBR sheet demand across sub-Saharan Africa, with the roofing sheets market projected to reach $1.4 billion USD by 2028 (MarketResearchFuture).

- Drivers: Urbanization, industrial rise, infrastructure investments

- Challenges: Quality standardization, skill gaps, maintenance

- Opportunities: Automation, custom profiles, high-strength/anti-corrosive coatings

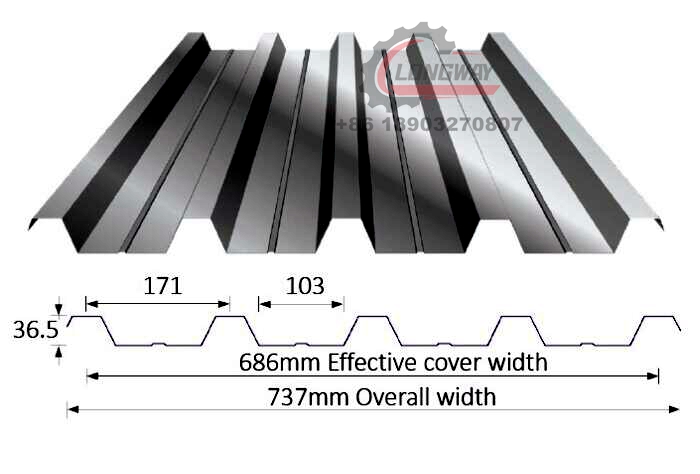

| Profile Name | Effective Width | Rib Height | Thickness Range | Main Material | Corrosion Resistance |

|---|---|---|---|---|---|

| 686 IBR | 686 mm | 35 mm | 0.3 - 0.8 mm | Galvanized Steel / PPGI | ISO 9227 Certified |

| 890 IBR | 890 mm | 35 mm | 0.35 - 1.0 mm | Galvalume/Alusan Steel | Salt Spray > 400 h |

The above standards highlight why the Africa 686 IBR roof sheet making machine (686mm effective width) is the most sought-after model for regional projects involving warehouse, school, airport, and residential roofing.

2. Africa 686 IBR Roof Sheet Making Machine: Technical Parameters & Process Flow

| Parameter | Specification |

|---|---|

| Feeding Width | 1000 mm (for 686mm effective width) |

| Material Thickness | 0.3 mm - 0.8 mm |

| Material Type | Galvanized Steel, PPGI, Aluminum, Galvalume |

| Production Speed | 15 - 30 m/min (Adjustable) |

| Forming Stations | 16-24 stations |

| Main Motor Power | 7.5 kW - 11 kW (Siemens/ABB) |

| Control System | Automatic PLC (Panasonic/Siemens), Touchscreen HMI |

| Cutting System | Hydraulic, Chrome-Treated Steel Blades (HRC ≥ 58°) |

| Roller Material | GCr15 Steel, CNC Machined, HRC 58-62 Surface |

| Applicable Standards | ISO 9001, CE, ANSI, SGS Certified |

| Installation Space | 8.5 m × 1.6 m × 1.3 m |

| Warranty | 2 Years Full Parts, Lifetime Technical Support |

Manufacturing & Operation Process Flow

- Decoiling: Automatic Decoiler supports up to 5 tons of coil, ensures smooth unrolling.

- Roll Forming: 16-24 stations, precision GCr15 steel rollers (CNC processed), ensures <0.5mm profile error

- Hydraulic Cutting: Blades CNC ground, hard chrome treatment, lifecycle > 500,000 cuts.

3. Advanced Manufacturing: Materials, Components, Certifications

- Rollers: GCr15 high-carbon tool steel, CNC lathed/grinded; HRC 58-62; high-wear, low distortion.

- Main Frame: Q235/Gr60 heavy-duty steel, full welding, laser cut, stress-relieved, paint/epoxy coated.

- Cutting Unit: Hydraulic, die blocks (HSS steel), chromed, tested for 500k cycles with micro-hardness checks.

- Detection: Each sheet output checked for size/angle by automated video gauge, <0.3% deviation (EN1090/ISO6382 test).

- Certifications: ISO 9001, CE, ANSI, SGS; manufacturing and QC traceable to batch number.

- Control: PLC with real-time diagnostics, remote assist, memory-backup.

4. Competitive Benchmark: Africa 686 IBR roof sheet making machine vs. Other Brands

| Parameter | Africa 686 IBR Roof Sheet Making Machine | Competitor A | Competitor B |

|---|---|---|---|

| Effective Width (mm) | 686 | 650 | 686 |

| Material Range | PPGI, GI, Aluminum, Galvalume | PPGI, GI | PPGI, GI, Aluminum |

| Production Speed (m/min) | 28 | 16 | 20 |

| Forming Method | CNC Rollers, Servo Control | Standard Rollers | Manual Adjustment |

| Certification | ISO, CE, ANSI | CE | ISO |

| Warranty | 2 Years | 1 Year | 1 Year |

| Service Lifetime | 25+ Years | 12 Years | 15 Years |

| Remote Support | Yes | No | No |

As clearly demonstrated, the Africa 686 IBR roof sheet making machine offers unmatched production speed, extended material versatility, and an industry-leading after-sale support system, endorsed by multi-national project partners and certified to international benchmarks.

5. Customization & Solution Engineering

- Profile Customization: Custom logo emboss, profile lock-ribs, capillary drain channels, interlock snap-fit options.

- Voltage/Frequency: Africa-standard 380V/50Hz; optional for 220V/60Hz, 415V/50Hz based on projects.

- Color/Coating: Integrated color-side change, support for PVDF, SMP, polyester coated sheets.

- Multi-width Modules: Adjustable guides for 610-900mm output by module changeover, multi-type integration.

- Automation Upgrades: Inline curving, punching, rib reinforcement add-ons, automatic stacker and packaging units.

- Onsite Commissioning: 7-20 days average, with virtual training + engineering onsite in Nigeria, Kenya, Ghana, South Africa, Egypt, Ethiopia.

6. Core Application Scenarios & Experience Case Studies

Case 1: Rapid Warehouse Roofing Deployment (Ghana, 2023)

- Project Scale: 24,000m² government food logistics center, Tema Port Zone

- Solution: 2 lines of Africa 686 IBR roof sheet making machine, inline hydraulic stacker, 0.5mm PPGI coil, Azure Blue (RAL 5005)

- Performance: 14 days full roof, installation efficiency +23% vs previous year, meeting ISO 9241 on panel flatness and color retention

- Client Quote: "Unmatched sheet accuracy, stable run, 4.6% material cost saving. Onsite support was professional." (Procurement Director, local contractor)

Case 2: School & Hospital Refurbishment (South Africa, 2022)

- Project Scale: Over 36 schools & 11 clinics upgraded, exceeding 46,000m²

- Material: Galvalume, 0.35-0.5mm, anti-corrosive coating, custom color for regional climate

- Benefit: Sheet life >25 years, decreased maintenance per ISO 9223, steady output in dust-prone environments

Case 3: Airport Hangar Roofing (Nigeria, 2023)

- Profile: 686 IBR with snap-lock ribs, length precision ±0.25mm (ANSI tolerance)

- Advantage: Withstood wind load per ASCE 7-16 category D, operational safety audit passed

Case 4: Water Treatment & Warehousing (Ethiopia, 2024)

- Industry: Water works / chemical plant, exposed to aggressive fumes

- Why Africa 686 IBR? High anti-corrosive material, enhanced coating bonded via CNC roller, less color fading, long sheet span reduces roof joints

7. Certifications, Partnerships & Authority Recognition

- Certifications: ISO 9001:2015, CE, SGS, ANSI compliance. Full batch traceability for all rolled sheets. SGS mechanical & environmental testing up to 800h salt spray.

- Key Clients: Dangote Group, Julius Berger, MTN Construction, SINOPEC Africa, Kenya Railways, Ghana Ministry of Infrastructure

- Service Network: Factories in China + Africa deployment offices (Lagos, Addis Ababa, Johannesburg). 14+ years in global supply.

- References: Industry quoted by major forums: RoofingAfrica.com, MCA

8. After-Sales, Delivery & Customer Support

- Delivery Cycle: 22-28 working days ex-works (ready for container111ize shipping, tested & commissioned)

- Warranty: 2 years (covers rolls, motors, drives, electronics). Consumables & quick-wear parts maintainable for life.

- Support: 24/7 online engineering support (WhatsApp, Email, Remote PLC), English/French local service.

- Training: Full operator manual, on-site or remote video commissioning. Operator certification programs available.

- Quality Promise: Each machine run-off testing recorded and video documented. Output profiles are laser measured for client validation prior to shipment.

- Spare Parts: All wear components in stock for 8 years minimum.

9. FAQ: Africa 686 IBR Roof Sheet Making Machine - Expert Answers

10. Conclusion & Industrial References

In the context of booming African construction and growing industrial agility, the Africa 686 IBR roof sheet making machine is the industry’s prime choice—in value, efficiency, and technical reliability. Its top-tier engineering, global-standard certification, and proven field record empower both manufacturers and end-users to achieve lasting project results.

- Reference: Roof sheet industry statistics: Statista Roofing Insights

- Research: “Design and Fabrication of IBR Roof Sheet Machines”, ResearchGate

- Industry Forum: RoofingAfrica.com/FORUM

- Journal: African Construction Review, “Automation & Quality Assurance for Roll Forming”, AfricanReview.com

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025