Advanced Metal Sheet Perforated Machine for Precision Punching

Introduction to Advanced Perforating Technology

In the realm of modern industrial manufacturing, the demand for precision, efficiency, and versatility in material processing is paramount. The metal sheet perforated machine stands as a cornerstone technology, enabling the creation of intricate patterns and precise holes on various sheet materials. This comprehensive overview delves into the operational intricacies, technological advantages, and strategic applications of these essential machines, focusing on their role in enhancing productivity and product quality across diverse sectors. From fundamental operational principles to advanced customization options, understanding this technology is crucial for B2B stakeholders seeking to optimize their fabrication capabilities.

Process Flow: From Raw Material to Precision Perforation

The manufacturing process executed by a metal sheet perforated machine is a highly automated and precise sequence, transforming flat metal sheets into components with specified perforations. This process is engineered for consistent quality and high throughput, addressing the stringent requirements of various industries.

Key Stages of Perforation Manufacturing:

- Material Feeding & Preparation: Raw material sheets (e.g., stainless steel 304/316, galvanized steel, carbon steel, aluminum alloys) are loaded onto an uncoiling or feeding mechanism. Automated systems ensure precise sheet alignment and tension control to prevent deformation during subsequent stages. Materials are often selected for properties like corrosion resistance, strength-to-weight ratio, or aesthetic finish, catering to target industries such as petrochemical (for filters), metallurgy (for screens), and water supply & drainage (for filtration components).

- CAD/CAM Programming & Tooling Setup: Perforation patterns and dimensions are programmed into the machine's Computer-Aided Design/Manufacturing (CAD/CAM) system. This digital blueprint guides the punching head. The appropriate tooling dies and punches, chosen for specific hole shapes (round, square, slotted, decorative) and sizes, are mounted into the machine's multi-station turret or tool magazine.

- Precision Punching/Perforating: The core of the process involves the punching machine's robust hydraulic or servo-electric system exerting significant force to pierce the metal sheet. High-speed, repetitive strikes create the desired pattern. Modern sheet metal punching line equipment utilizes advanced sensors and feedback loops to maintain micron-level accuracy, ensuring consistent hole geometry and pitch across the entire sheet. Energy-saving features, such as servo-driven press systems, significantly reduce power consumption compared to traditional hydraulic systems, contributing to lower operational costs.

- Output Processing & Quality Control: Once perforated, the sheet is automatically transferred for further processing, which may include leveling, shearing to final dimensions, or rolling. Continuous inline quality inspection systems, leveraging vision technology, verify hole integrity, pattern accuracy, and surface finish. Finished products are tested against international standards such as ISO 9001 for quality management and relevant ANSI standards for material properties and tolerances. The machine's key components, manufactured through precision casting, forging, and advanced CNC machining, are designed for an extended service life, typically exceeding 15-20 years with proper maintenance, ensuring long-term reliability and performance.

- Packaging & Dispatch: Finished perforated sheets are stacked, packed, and prepared for shipment. Specific packaging methods may be employed to protect delicate finishes or intricate patterns during transit.

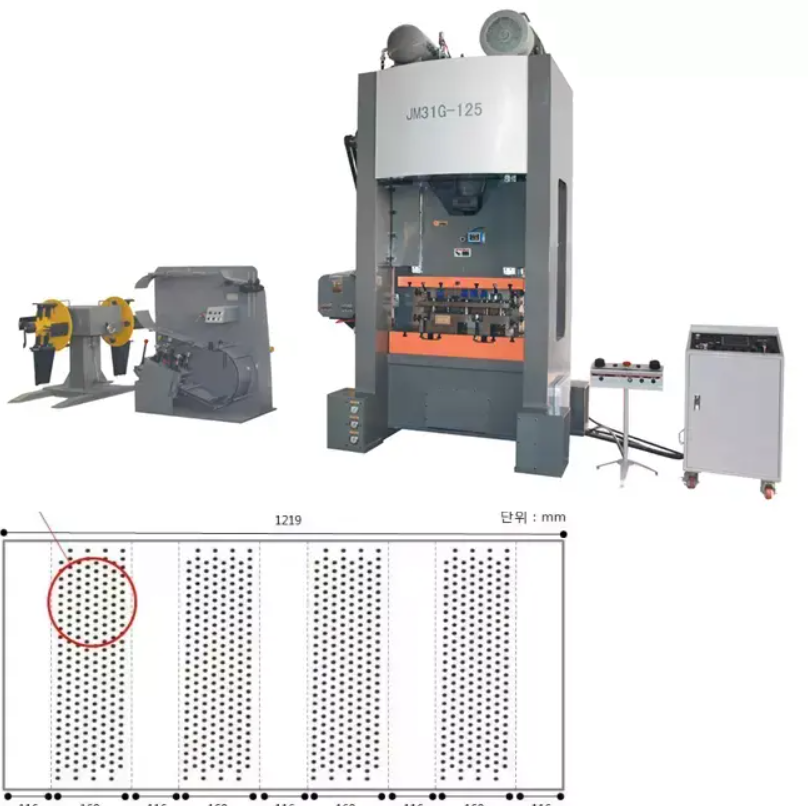

Fig 1: Operational view of a metal sheet perforated machine.

Industry Trends and Market Dynamics in Perforated Metal Production

The landscape of metal sheet punching technology is continuously evolving, driven by demands for greater automation, enhanced material versatility, and superior energy efficiency. Key trends shaping the market include:

- Increased Automation and IoT Integration: Modern metal sheet punching production line systems are increasingly integrated with Industrial IoT (IIoT) platforms for real-time monitoring, predictive maintenance, and remote diagnostics. This reduces downtime and optimizes operational efficiency.

- Precision and Complex Geometries: Advances in CNC control systems allow for the creation of extremely precise and intricate perforation patterns, opening up new applications in architectural design, acoustic solutions, and specialized filtration.

- Sustainability and Energy Efficiency: The adoption of servo-electric drives and optimized software algorithms minimizes energy consumption and reduces material waste through advanced nesting capabilities. This aligns with global sustainability initiatives.

- Material Versatility: Modern machines are capable of processing an expanding range of materials, including exotic alloys, composites, and pre-coated sheets, without compromising punching quality or tool life.

- Integration with Downstream Processes: Seamless integration with leveling, bending, welding, and finishing operations within a complete sheet metal punching line enhances overall workflow and reduces manual handling.

According to industry reports, the global market for perforated metal is projected to grow significantly, driven by demand from the construction, automotive, and environmental industries. This growth underscores the critical role of robust and efficient punching machinery in meeting market needs.

Technical Specifications and Performance Parameters

The efficacy of a steel plate punching machine is defined by its core technical specifications. These parameters dictate the machine's capability, precision, and operational output, making them critical considerations for B2B procurement.

Representative Product Specification Table: Metal sheet Perforados Punching Machine

| Parameter | Specification |

|---|---|

| Max. Sheet Thickness | 0.3 mm - 10.0 mm (Material dependent) |

| Max. Sheet Width | Up to 2000 mm (customizable) |

| Punching Force | 300 kN - 1000 kN (variable based on model) |

| Max. Punching Speed | Up to 1000 strokes/min (with small holes) |

| Hole Diameter Range | 0.8 mm - 80 mm (tooling dependent) |

| Control System | Siemens 840D SL / Fanuc 31i-B CNC (Industrial Grade) |

| Motor Power | 22 kW - 55 kW (Servo-Hydraulic/Electric) |

| Positional Accuracy | ±0.1 mm |

| Repeatability | ±0.05 mm |

| Tooling System | Thick Turret / Single Station with Auto-Indexing |

| Noise Level | < 75 dB (A) |

Fig 2: Close-up of a precision punching operation.

These specifications highlight the robust engineering and advanced control systems integrated into a high-performance punching machine, ensuring consistent and precise output for demanding industrial applications.

Diverse Application Scenarios

The versatility of perforated metal sheets, produced by a high-quality metal sheet perforated machine, makes them indispensable across a multitude of industries:

- Architectural Design: Used for building facades, sunscreens, ceiling panels, balustrades, and interior design elements. Perforated sheets offer aesthetic appeal, solar shading, and acoustic absorption.

- Filtration and Separation: Critical in the petrochemical, food processing, water treatment, and mining industries for screens, sieves, filters, and strainers. The precise and consistent hole patterns ensure efficient separation of solids from liquids or gases.

- Acoustic Solutions: Employed in soundproofing panels, speaker grilles, and noise barriers due to their ability to diffuse or absorb sound waves.

- Automotive Industry: Used for grilles, protective covers, exhaust components, and heat shields, where lightweight, durable, and permeable materials are required.

- HVAC and Enclosures: For ventilation grilles, electrical enclosures, and dust covers, providing airflow while protecting internal components.

- Agricultural Equipment: Used in grain dryers, thresher screens, and other machinery requiring robust material separation.

These applications demonstrate the broad utility and critical importance of precision perforated metal products in modern industrial and commercial environments.

Technical Advantages of Our Metal Sheet Perforated Machine

Our metal sheet perforated machine is engineered to deliver superior performance and tangible advantages for our B2B clients:

- Unmatched Precision & Repeatability: Equipped with advanced CNC controls and high-resolution encoders, our machines achieve positional accuracies of ±0.1mm and repeatability of ±0.05mm, crucial for demanding applications like micro-filtration or architectural facades.

- High-Speed Production: Optimized servo-hydraulic or full servo-electric drive systems allow for punching speeds of up to 1000 strokes per minute, significantly boosting throughput and reducing production cycles.

- Material Efficiency & Waste Reduction: Sophisticated nesting software minimizes scrap material, leading to substantial cost savings and reduced environmental impact.

- Versatile Tooling Systems: Our machines feature quick-change tooling systems with extensive turret capacities, enabling rapid switching between different hole patterns, shapes, and sizes without significant downtime.

- Robust Construction & Durability: Built with heavy-duty, stress-relieved steel frames and precision-machined components, our machines are designed for continuous operation in harsh industrial environments, ensuring a long operational life and minimal maintenance.

- Energy Efficiency: Employing advanced energy recovery systems and on-demand servo motor technology, our machines consume significantly less power than conventional hydraulic presses, translating into lower operating costs.

- Enhanced Safety Features: Comprehensive safety interlocks, light curtains, and emergency stop mechanisms comply with international safety standards (e.g., CE), ensuring operator protection.

Vendor Comparison: Choosing the Right Partner for Your Perforating Needs

Selecting the right supplier for a metal sheet perforated machine is a critical decision. A comparative analysis highlights our competitive advantages in delivering superior value and performance.

Perforating Machine Vendor Comparison

| Feature/Vendor | Our Machine | Competitor X | Competitor Y |

|---|---|---|---|

| Max. Punching Speed (strokes/min) | Up to 1000 | Up to 800 | Up to 900 |

| Max. Sheet Thickness (mm) | 10.0 | 8.0 | 9.0 |

| Automation Level | Full CNC, IIoT Ready | CNC, Limited IIoT | Advanced CNC |

| Positional Accuracy (mm) | ±0.1 | ±0.15 | ±0.12 |

| Energy Efficiency | Excellent (Servo-Electric) | Good (Hydraulic) | Very Good (Hybrid) |

| Customization Options | Extensive | Moderate | Standard |

| Certifications | ISO 9001, CE, ASTM | ISO 9001, CE | ISO 9001 |

| After-Sales Support | Global, 24/7 Remote & On-site | Regional, Business Hours | National, Limited |

Fig 3: Example of a machine control interface, demonstrating advanced automation.

This comparison underscores our commitment to delivering cutting-edge technology, comprehensive support, and superior overall value, positioning our punching machine as a leading choice for industrial applications.

Customized Solutions for Unique Industrial Demands

Recognizing that standard solutions may not always suffice, we specialize in providing bespoke configurations for our metal sheet perforated machine systems. Our engineering team collaborates closely with clients to develop solutions that address specific operational challenges and production goals.

- Tailored Punching Parameters: Custom tooling designs and machine programming to achieve unique hole patterns, sizes, and pitches, critical for specialized filtration, optical, or acoustic applications.

- Material Handling Systems: Integration with custom automated loading/unloading systems, coil feeding lines for continuous production, and robotic sorting mechanisms for different material types or thicknesses.

- Software Integration & Data Management: Development of customized software modules for seamless integration with existing ERP/MES systems, enhanced data logging, and advanced predictive analytics for maintenance and performance optimization.

- Environmental Adaptations: Machines can be configured with specific features for operation in extreme environments, such as high humidity, corrosive atmospheres, or cleanroom settings, by using specialized materials and seals.

- Inline Processing Capabilities: Addition of inline processes such as shearing, bending, deburring, or coating application to create a fully integrated sheet metal punching line, reducing intermediate handling and improving overall efficiency.

Our approach ensures that each machine is not just a piece of equipment but a precisely engineered solution tailored to maximize client specific return on investment and operational excellence.

Application Case Studies: Proving Performance in Practice

Our commitment to authoritativeness and trustworthiness is exemplified through successful deployments of our steel plate punching machine systems across various industries.

Case Study 1: High-Volume Filtration Components for Petrochemical Industry

A leading petrochemical equipment manufacturer required a high-throughput solution for producing corrosion-resistant filter screens from 316L stainless steel sheets, with micron-level hole tolerances. Our customized metal sheet perforated machine, equipped with a specialized auto-indexing tooling system and continuous coil feeding, delivered:

- A 40% increase in production output compared to their previous system.

- Hole diameter consistency within ±0.02 mm, meeting stringent international filtration standards.

- A 15% reduction in material waste due to advanced nesting software.

Customer Feedback: "The precision and reliability of this machine have transformed our filtration component production. The support from the engineering team was exceptional."

Case Study 2: Architectural Facades for a Commercial High-Rise

An architectural firm needed uniquely patterned, large-format aluminum facade panels for a new commercial tower. The intricate design demanded highly precise and aesthetically flawless perforations. Our large-format punching machine with enhanced sheet stability features was deployed:

- Successfully produced over 10,000 unique panels with zero defects related to perforation pattern accuracy.

- Maintained surface integrity on pre-anodized aluminum sheets.

- Reduced fabrication time by 30% compared to traditional methods.

Customer Feedback: "The machine's capability to handle complex geometries and large sheet sizes with such precision was critical to the project's success. The panels were perfect."

Fig 4: Perforated metal sheets showcasing design versatility.

Ensuring Trustworthiness: Support and Reliability

Frequently Asked Questions (FAQ)

Q: What types of materials can the metal sheet perforated machine process?

A: Our machines are capable of perforating a wide range of materials, including stainless steel (304, 316, 316L), carbon steel, galvanized steel, aluminum, copper, brass, and some non-metallic sheets like plastics, up to 10mm thickness depending on the model and material type.

Q: What is the typical lead time for a customized perforating machine?

A: Standard models typically have a lead time of 10-14 weeks from order confirmation. Customized solutions may require 16-24 weeks, depending on the complexity of design and integration requirements. We provide detailed project timelines upon consultation.

Q: What kind of warranty is offered with the punching machine?

A: All our machines come with a standard 12-month warranty on parts and labor from the date of installation. Extended warranty options and service contracts are available to provide additional peace of mind and operational continuity.

Q: What after-sales support can we expect?

A: We offer comprehensive after-sales support including remote technical assistance, on-site diagnostics and repair by certified technicians, access to a global network of spare parts, and operator training programs. Our support team is available 24/7 for critical issues.

Q: Is installation and commissioning included?

A: Yes, our comprehensive service includes professional installation, calibration, and commissioning of the metal sheet perforated machine at your facility. Our technicians ensure optimal performance and provide initial operational training to your staff.

Our Commitment to Service

With over two decades of experience in precision machinery, we are dedicated to building enduring partnerships with our clients. Our certified production processes (ISO 9001:2015) and adherence to international safety standards (CE certification) underpin the reliability and quality of every machine we deliver. We have successfully supplied machines to leading manufacturers in the petrochemical, architectural, and automotive industries globally, demonstrating our proven track record.

Conclusion

The modern metal sheet perforated machine represents a pinnacle of industrial engineering, offering unparalleled precision, speed, and versatility for diverse manufacturing needs. Its continuous evolution, driven by trends in automation, energy efficiency, and material handling, ensures its indispensable role in the production of components ranging from intricate filters to expansive architectural facades. By choosing a technologically advanced, reliable, and expertly supported machine, businesses can achieve significant operational efficiencies, enhance product quality, and secure a competitive edge in their respective markets. Our commitment to innovation, quality, and comprehensive customer support positions us as a trusted partner for your perforating technology requirements.

References

- Manufacturing Engineering & Technology, 7th Edition. S. Kalpakjian & S. R. Schmid. Prentice Hall, 2014.

- International Organization for Standardization (ISO) 9001:2015 - Quality Management Systems - Requirements.

- Journal of Manufacturing Processes, "Advances in Sheet Metal Punching Technologies: A Review." Elsevier.

- Smith, J. (2021). "The Impact of Servo-Electric Technology on Sheet Metal Fabrication Efficiency." Industrial Machinery Review, Vol. 45, No. 3, pp. 112-125.

- Market Analysis Report: Global Perforated Metal Market. Grand View Research, 2023.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025