High-Precision Deck 950 Composite Slab/Panel Forming Machine

Introduction to Advanced Roll Forming Technology

In modern construction, the demand for high-strength, lightweight, and rapidly deployable structural solutions has led to significant advancements in metal profiling machinery. At the forefront of this innovation is the Maquina para PLACA/PANEL COLABORANTE Deck 950, a sophisticated roll forming system engineered for the precise and efficient production of composite floor decking. This specialized machinery is critical for fabricating steel deck profiles that integrate seamlessly with concrete slabs, providing both permanent formwork and positive reinforcement for superior structural integrity.

The structural steel decking produced by such machines offers a myriad of benefits, including reduced construction time, material optimization, and enhanced safety on site. The Deck 950 profile, specifically, is renowned for its optimal balance of steel strength and concrete adhesion, facilitating a collaborative action that results in a highly robust floor system. Our discussion will delve into the intricate manufacturing process of this essential machine, its technical specifications, market trends, and its profound impact on the B2B landscape.

Manufacturing Process Flow of the Roll Forming Machine

The creation of a high-performance roll forming machine, such as the Maquina para PLACA/PANEL COLABORANTE Deck 950, involves a meticulously engineered process flow designed to ensure precision, durability, and reliability. This multi-stage manufacturing journey begins with raw material selection and culminates in rigorous performance testing.

1. Raw Material Procurement and Preparation

- Steel Coils: High-grade structural steel (e.g., Q235, Q345) is sourced for the main frame and structural components, ensuring robust support and vibration dampening.

- Alloy Steels for Rollers: Critical forming rollers are typically crafted from premium bearing steel (e.g., GCr15, Cr12Mov) or 45# steel with subsequent heat treatment. These materials are chosen for their exceptional hardness, wear resistance, and ability to maintain profile accuracy over millions of cycles.

- Hydraulic and Electrical Components: Precision-engineered hydraulic pumps, valves, motors, and advanced PLC control systems are procured from reputable global suppliers, adhering to international standards for performance and safety.

2. Component Fabrication and Machining

- Frame Construction: The machine's main frame undergoes precision cutting, welding, and annealing. Welding processes are performed by certified technicians to prevent residual stress, followed by shot blasting and painting for corrosion resistance.

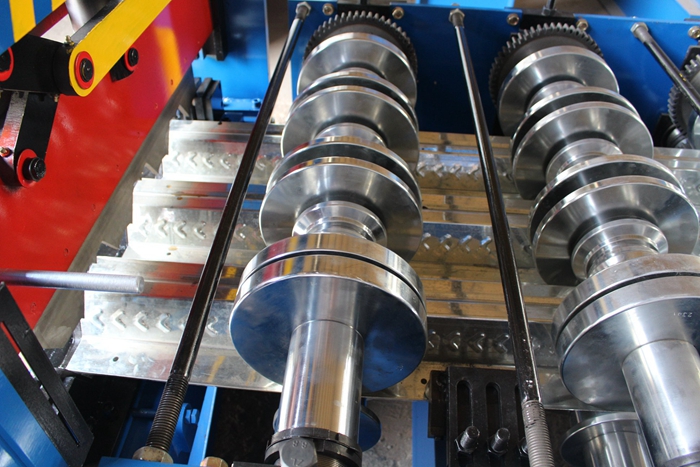

- Roller Manufacturing: This is a highly critical step. Raw alloy steel is initially forged for enhanced grain structure. It then undergoes multi-axis CNC machining to achieve the exact profile dimensions required for the Deck 950 panel. After machining, the rollers are heat-treated (e.g., quenching and tempering) to achieve a surface hardness of HRC58-62, followed by hard chrome plating for superior wear resistance and a low coefficient of friction.

- Shaft and Gear Production: High-strength steel shafts are precision-ground, and gears are hobbed and heat-treated to ensure smooth power transmission and long operational life.

- Cutter Blade Fabrication: Shear blades, often made from Cr12Mov, are precision-ground and heat-treated to achieve optimal hardness and edge retention for clean, burr-free cutting.

3. Assembly and Integration

- Individual components are meticulously assembled. This includes mounting the decoiler, feeding guide, roll forming stations, hydraulic cutting mechanism, and the output stacker.

- The hydraulic power unit is integrated, and all hydraulic lines are connected and pressure-tested.

- Electrical wiring, sensor installation, and PLC programming are executed to establish the automated control system. This ensures seamless operation and precise synchronization of all machine functions.

4. Quality Control and Testing Standards

Every Maquina para PLACA/PANEL COLABORANTE Deck 950 undergoes stringent quality control procedures in accordance with international standards such as ISO 9001 for quality management and relevant ANSI/ASTM standards for material specifications.

- Dimensional Accuracy: Each roller set is inspected with CMM (Coordinate Measuring Machine) to ensure precise profile geometry.

- Material Hardness: Hardness testing (Rockwell/Brinell) is performed on heat-treated components to verify specified values.

- Run-out and Alignment: Dynamic balancing and alignment checks are performed on shafts and rollers to minimize vibration and maximize bearing life.

- Functional Testing: The assembled machine undergoes extensive dry run and production trials using actual material to verify forming accuracy, cutting precision, speed, and overall system stability. Electrical safety checks are performed according to CE standards.

5. Service Life and Target Industries

With proper maintenance, a well-engineered Maquina para PLACA/PANEL COLABORANTE Deck 950 is designed for a service life exceeding 15-20 years. Its robust construction and high-quality components ensure sustained performance in demanding industrial environments.

Target industries for the output (Deck 950 panels) primarily include large-scale construction projects across various sectors:

- High-Rise Buildings: Commercial and residential skyscrapers benefit from rapid floor installation.

- Industrial Facilities: Factories, warehouses, and logistics centers require strong, durable floor systems.

- Infrastructure Projects: Bridges, car parks, and power plants utilize composite decking for structural efficiency.

- Retail and Commercial Centers: Shopping malls and office complexes demand long-span capabilities and fire resistance.

Advantages in Application Scenarios:

The panels produced by the Maquina para PLACA/PANEL COLABORANTE Deck 950 offer significant advantages:

- Energy Saving: By reducing wet concrete usage and shortening curing times, construction projects see reduced energy consumption for heating/cooling and faster project completion.

- Corrosion Resistance: Typically produced from galvanized or pre-painted steel, the deck panels exhibit excellent resistance to corrosion, ensuring a longer structural lifespan even in challenging environments like coastal areas or industrial zones.

- Structural Efficiency: The composite action with concrete optimizes material use, leading to lighter floor slabs with equivalent or superior strength to traditional methods.

Current Industry Trends in Roll Forming Technology

The roll forming industry is undergoing a transformative period, driven by evolving construction demands, material innovations, and the overarching push for greater efficiency and sustainability. Key trends influencing machines like the Maquina para PLACA/PANEL COLABORANTE Deck 950 include:

- Increased Automation and IoT Integration: Modern roll forming lines are increasingly equipped with advanced PLC (Programmable Logic Controller) systems, HMI (Human-Machine Interface) touchscreens, and even IoT (Internet of Things) capabilities. This enables real-time monitoring, predictive maintenance, and remote diagnostics, significantly reducing downtime and optimizing production.

- Higher Precision and Repeatability: The demand for tighter tolerances in finished products, especially in high-stress structural applications, mandates roll forming machines with superior engineering and component quality. Advanced servo-driven systems ensure precise control over forming speed and cutting, minimizing material waste and enhancing product consistency.

- Multi-Profile Capability: To maximize machine utilization and cater to diverse project requirements, there's a growing trend towards quick-change cassette systems or adjustable tooling that allows a single machine to produce multiple decking profiles with minimal changeover time.

- Energy Efficiency: With rising energy costs and environmental concerns, manufacturers are focusing on integrating energy-efficient motors (e.g., IE3/IE4 rated), smart hydraulic systems, and optimized machine designs to reduce power consumption during operation.

- Material Versatility: While galvanized steel remains dominant, there's increasing interest in roll forming high-strength low-alloy (HSLA) steels and even aluminum alloys for specific applications, requiring machines to be more adaptable to varying material properties and thicknesses.

These trends collectively push the boundaries of what roll forming technology can achieve, delivering more versatile, efficient, and reliable solutions to the construction sector.

Technical Specifications and Parameters

The performance and output quality of a roll forming machine are directly dictated by its core technical specifications. The Maquina para PLACA/PANEL COLABORANTE Deck 950 is designed with parameters optimized for high-volume, precision manufacturing of structural decking panels. Below is a comprehensive table detailing the typical specifications for such an advanced system.

Product Specification Table: Maquina para PLACA/PANEL COLABORANTE Deck 950

| Parameter | Specification |

|---|---|

| Effective Width of Decking | 950 mm |

| Material Width (Coil) | 1250 mm |

| Material Thickness Range | 0.7 mm - 1.2 mm (Galvanized Steel, Prepainted Steel) |

| Roll Forming Speed | 10 - 15 meters per minute (adjustable) |

| Number of Forming Stations | Approximately 20-22 stations (optimised for Deck 950 profile) |

| Main Motor Power | 11 kW - 15 kW (depending on configuration) |

| Hydraulic System Power | 5.5 kW - 7.5 kW |

| Material of Rollers | 45# Steel, Chrome Plated (Optional: GCr15 or Cr12 with heat treatment) |

| Hardness of Rollers | HRC 58-62 (after heat treatment) |

| Material of Cutting Blade | Cr12Mov Steel (with quenching treatment) |

| Control System | PLC Control (e.g., Siemens, Panasonic) with Touch Screen HMI |

| Transmission Type | Chain Drive or Gear Box (depending on specific model) |

| Machine Dimensions (Approx.) | 8500mm (L) x 1500mm (W) x 1500mm (H) |

| Total Weight (Approx.) | 8000 kg - 10000 kg |

These specifications highlight the robust engineering behind the Maquina para PLACA/PANEL COLABORANTE Deck 950, ensuring its capability to consistently deliver high-quality decking panels that meet stringent construction standards.

Application Scenarios and Technical Advantages

The versatility and structural efficiency of the Deck 950 profile, produced by the Maquina para PLACA/PANEL COLABORANTE Deck 950, make it an indispensable component in a wide array of modern construction projects.

Typical Application Scenarios:

- Multi-Story Commercial Buildings: Used extensively in office towers and shopping complexes where speed of construction, fire resistance, and superior load-bearing capacity are paramount. The composite action significantly reduces slab thickness and overall building weight.

- Parking Structures: The long-span capabilities and robust nature of Deck 950 panels are ideal for multi-level parking garages, resisting heavy dynamic loads and providing excellent durability.

- Industrial Warehouses and Factories: For facilities requiring large, open floor plans and the ability to withstand heavy machinery and storage, composite decks offer an economical and structurally sound solution.

- Educational and Healthcare Facilities: Projects demanding expedited construction schedules, stringent safety standards, and long-term structural integrity benefit significantly from roll-formed decking.

- Residential High-Rises: Provides a fast, efficient, and cost-effective method for constructing floor systems in modern apartment buildings and condominiums.

Key Technical Advantages:

- Superior Load-Bearing Capacity: The unique profile geometry of Deck 950, combined with its collaboration with concrete, results in a composite slab with exceptionally high strength-to-weight ratio, capable of handling significant live and dead loads.

- Optimized Material Usage: The advanced design maximizes the structural contribution of both steel and concrete, often leading to reduced material quantities compared to traditional concrete slabs, thus lowering costs and environmental impact.

- Rapid Installation: As a permanent formwork, the decking eliminates the need for temporary shoring in many cases, significantly accelerating construction schedules and reducing labor costs. Its lightweight nature also simplifies handling.

- Fire Resistance: When properly integrated into a fire-rated floor assembly, composite decking provides excellent fire resistance, enhancing building safety and code compliance.

- Excellent Shear Connection: The intricate embossments and profile shape of the Deck 950 provide a robust mechanical interlock with the concrete, ensuring effective shear transfer and preventing delamination.

- Enhanced Structural Durability: The galvanized steel base offers superior corrosion protection, ensuring the long-term integrity and service life of the composite floor system.

Vendor Comparison and Customized Solutions

Selecting the right manufacturer for a specialized roll forming machine like the Maquina para PLACA/PANEL COLABORANTE Deck 950 is a critical decision for any B2B enterprise. While many vendors offer similar equipment, significant differences often exist in terms of quality, customization capabilities, and post-sales support.

Vendor Comparison Considerations:

When evaluating suppliers, it is crucial to look beyond the initial purchase price and consider the total cost of ownership (TCO) which includes factors such as machine longevity, maintenance requirements, and the consistency of output quality.

- Quality of Components: Leading manufacturers utilize premium-grade components (e.g., brand-name PLCs, high-quality steel for rollers and shafts) that contribute to the machine's reliability and extended service life. Inferior components can lead to frequent breakdowns and costly repairs.

- Engineering Expertise: Reputable vendors possess deep engineering knowledge, offering optimized roll tool designs that minimize material stress and maximize profile accuracy. This expertise is vital for consistently producing Deck 950 panels that meet strict structural codes.

- After-Sales Support: A robust support system, including spare parts availability, technical assistance, and on-site service, is paramount. Some vendors may offer lower upfront costs but lack comprehensive support, leading to significant operational challenges.

- Certifications and Standards: Adherence to international quality (ISO 9001) and safety (CE) standards indicates a commitment to excellence and compliance.

Customized Solutions: Tailoring to Specific Project Needs

Recognizing that every client and project has unique requirements, customization is a core offering for advanced roll forming solutions. For the Maquina para PLACA/PANEL COLABORANTE Deck 950, customization can extend to several critical areas:

- Material Flexibility: While the standard machine handles galvanized steel, options for processing higher tensile strength materials or specific alloy grades can be integrated, requiring adjustments to roller material, heat treatment, and motor power.

- Production Speed: For clients demanding exceptionally high output, the machine can be configured with enhanced motor power and optimized control systems to achieve faster line speeds while maintaining precision.

- Automation Level: From basic semi-automatic systems to fully integrated, intelligent production lines with automatic coil loading, stacking, and bundling, the level of automation can be tailored to match operational requirements and budget.

- Punching and Notching Units: Integrated pre-punching or post-punching units can be added to create specific bolt holes, cut-outs, or embossments for services (e.g., electrical conduits), eliminating secondary operations.

- Control System Localization: The PLC and HMI can be programmed in multiple languages and adapted to local electrical standards, ensuring ease of operation for global clients.

Application Case Studies & Client Success

The proven track record of the Maquina para PLACA/PANEL COLABORANTE Deck 950 is best illustrated through its successful deployment in diverse, demanding construction projects globally. Our commitment to delivering high-performance machinery is reflected in the tangible benefits realized by our clients.

Case Study 1: Large-Scale Commercial High-Rise in a Metropolitan Area

A prominent construction group was contracted for a 40-story commercial office tower requiring over 150,000 square meters of composite floor decking. Their primary challenges included a tight construction schedule and the need for consistent, high-quality panels to meet stringent structural codes. By investing in our advanced Maquina para PLACA/PANEL COLABORANTE Deck 950, the client achieved:

- 40% Reduction in Floor Construction Time: The machine's high production speed (15 m/min) and precise cutting capabilities enabled on-site fabrication, minimizing logistics and accelerating slab pouring.

- Enhanced Material Efficiency: Optimal profile design ensured less steel waste, contributing to a 10% saving in material costs.

- Superior Panel Consistency: The machine’s PLC control system maintained precise dimensions and shear stud embossments, significantly reducing defects and rework.

Customer Feedback: "The reliability and precision of this machine were instrumental in keeping our project on schedule and within budget. The support team was also highly responsive." - Project Director, Leading Construction Firm.

Case Study 2: Industrial Manufacturing Plant Expansion

An industrial client undertaking a major expansion of their manufacturing facility required durable, heavy-duty floor decking capable of supporting substantial machinery and dynamic loads. They sought a solution that offered long-term structural integrity and corrosion resistance, given the typical industrial environment.

- Robust Structural Support: The Deck 950 panels, produced from thicker gauge galvanized steel using our machine, provided the necessary strength and stiffness for the industrial floor, surpassing initial load requirements.

- Long-Term Durability: The high-quality galvanized finish of the panels ensured exceptional corrosion resistance, crucial for the humid and chemically active plant environment.

- Reduced Maintenance: The robust construction of both the machine and its output panels contributed to a floor system requiring minimal long-term maintenance, a significant operational cost saving.

These cases exemplify how the technical prowess and operational reliability of our roll forming machinery translate into tangible success for our B2B partners across various sectors. Our firm has consistently served the global market for over 15 years, building a reputation for engineering excellence and dependable service.

Trustworthiness & Support: FAQ, Lead Time, Warranty, Customer Service

Building and maintaining trust with our B2B clients is paramount. This section addresses common inquiries and outlines our comprehensive commitment to support and reliability for every Maquina para PLACA/PANEL COLABORANTE Deck 950.

Frequently Asked Questions (FAQ)

- Q1: What materials can the machine process?

A1: Our Maquina para PLACA/PANEL COLABORANTE Deck 950 is primarily designed for galvanized steel, but can be adapted to process pre-painted steel, cold-rolled steel, and specific high-strength low-alloy (HSLA) steels within the specified thickness range (0.7mm - 1.2mm). - Q2: What is the expected lifespan of the rollers?

A2: With proper maintenance and use within specified material parameters, the heat-treated and chrome-plated rollers are designed for a service life exceeding 5 million linear meters of production. - Q3: Is on-site installation and training provided?

A3: Yes, we offer comprehensive on-site installation supervision and operational training by our expert engineers to ensure your team is fully proficient in operating and maintaining the equipment. - Q4: How does the machine handle different panel lengths?

A4: The machine's PLC control system allows for programmable cutting lengths, enabling automatic production of panels to precise, varying specifications as required by the construction plan. - Q5: What safety features are integrated into the machine?

A5: The machine incorporates multiple safety features, including emergency stop buttons, protective guarding over moving parts, photoelectric sensors for material detection, and overload protection for motors, adhering to international safety standards.

Lead Time and Fulfillment

Our standard lead time for the Maquina para PLACA/PANEL COLABORANTE Deck 950 typically ranges from 60 to 90 working days, depending on customization requirements and current production schedules. This duration accounts for precision manufacturing, rigorous testing, and quality control. We provide detailed project timelines upon order confirmation and maintain transparent communication throughout the manufacturing process. Expedited options may be available upon request.

Warranty Commitments

We stand behind the quality of our engineering. Each Maquina para PLACA/PANEL COLABORANTE Deck 950 comes with a comprehensive 12-month warranty from the date of installation or 18 months from the date of shipment (whichever comes first). This warranty covers manufacturing defects and component failures under normal operating conditions. Specific wear parts are excluded; however, their quality is guaranteed at the time of delivery. Extended warranty options are also available.

Dedicated Customer Support and After-Sales Service

Our commitment to client success extends far beyond the sale. We offer a multi-tiered customer support system:

- 24/7 Technical Hotline: Access to our experienced technicians for immediate troubleshooting and guidance.

- Remote Diagnostics: Leveraging PLC capabilities for remote access and diagnostic checks to resolve issues efficiently.

- Global On-Site Service: Our team of field engineers is available for dispatch for complex installations, major repairs, and preventative maintenance schedules worldwide.

- Spare Parts Availability: We maintain a comprehensive inventory of genuine spare parts, ensuring rapid dispatch to minimize machine downtime.

- Regular Maintenance Contracts: Tailored service agreements designed to optimize machine performance and extend operational life.

Conclusion

The Maquina para PLACA/PANEL COLABORANTE Deck 950 represents a pinnacle of roll forming technology, offering unparalleled precision, efficiency, and versatility for the production of composite floor decking. Its robust design, advanced automation features, and ability to meet stringent industry standards make it an indispensable asset for modern construction firms seeking to optimize their operations and deliver superior structural solutions. By understanding its detailed manufacturing process, technical capabilities, and the comprehensive support systems in place, B2B decision-makers can confidently invest in a machine that promises long-term performance and significant return on investment.

This machine is not just equipment; it is a strategic investment in the future of construction, enabling faster project completion, reduced material waste, and the creation of safer, more resilient buildings.

References

- American Society for Testing and Materials (ASTM) Standards for Steel Deck and Cold-Formed Steel Structures.

- International Organization for Standardization (ISO) 9001: Quality Management Systems - Requirements.

- Roll Forming Handbook by George T. Halmos, Marcel Dekker, Inc.

- Journal of Construction Engineering and Management, American Society of Civil Engineers.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025