Africa 686 IBR Roof Sheet Making Machine-Cangzhou Longway International Trade Co., Ltd.|High Production Capacity&Customizable Profiles

Introduction to the Africa 686 IBR Roof Sheet Making Machine

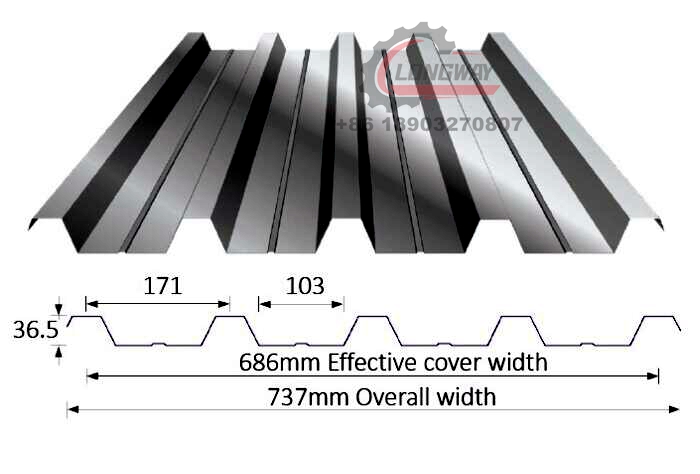

The Africa 686 IBR Roof Sheet Making Machine is a cutting-edge roll forming solution designed to produce high-quality IBR (Inverted Box Rib) metal roofing sheets. This machine is tailored for the African market, offering a balance of durability, efficiency, and cost-effectiveness. Its advanced engineering ensures precision in creating trapezoidal profiles, which are widely preferred for their structural integrity and aesthetic appeal.

The machine's versatility allows it to process materials such as PPGI (Pre-Painted Galvanized Iron), PPGL (Pre-Painted Galvanized Aluminum), and GI (Galvanized Iron) coils, with thicknesses ranging from 0.3mm to 0.8mm. This adaptability makes it ideal for various construction projects, from residential to industrial applications.

Key Features and Advantages

The Africa 686 IBR Roof Sheet Making Machine stands out due to its robust design and advanced functionalities. Here are some of its key features:

- High Production Capacity: With a forming speed of 15-20 meters per minute, the machine ensures efficient mass production, reducing downtime and increasing profitability.

- Customizable Profiles: The machine supports both standard and custom-designed profiles, including wide-span roofing sheets and self-locking panels, catering to specific client requirements.

- Material Efficiency: The trapezoidal rib design maximizes the strength-to-weight ratio, minimizing material waste while maintaining structural integrity.

- Advanced Control System: Equipped with a PLC Delta control system and a touch screen interface, the machine offers precise operation and easy monitoring.

- Durability and Precision: The use of high-grade forged steel rollers and a 350mm H-beam structure ensures long-term durability and high-precision output.

Technical Specifications

The Africa 686 IBR Roof Sheet Making Machine is engineered to meet the highest standards of performance and reliability. Below is a detailed overview of its technical specifications:

| Parameter | Specification |

|---|---|

| Material Type | PPGI, PPGL, GI |

| Sheet Thickness Range | 0.3 - 0.8mm |

| Coil Width | 914/925mm |

| Power Requirement | 380V/3Ph/50Hz (Customizable) |

| Main Motor Power | 4+4kW |

| Cutter Power | 4kW |

| Forming Speed | 15-20m/min |

| Machine Frame | 350mm H Beam Structure |

| Roller Material | High Grade 45# Forged Steel |

| Forming Stations | 14-18 Rows |

| Transmission Type | Chain Drive (1-inch Double Chain) |

| Cutting Type | Hydraulic Pillar Type and Length-Set Cutting |

| Control System | PLC Delta + Inverter Delta |

| Dimensions (Approx.) | 7.5m × 1.5m × 1.2m |

| Total Weight (Approx.) | 4.6T |

Applications and Industry Impact

The Africa 686 IBR Roof Sheet Making Machine is designed for a wide range of applications, making it a versatile asset for manufacturers and construction companies. Its primary uses include:

- Residential Construction: Producing durable and aesthetically pleasing roofing sheets for homes and small buildings.

- Industrial Facilities: Manufacturing large-scale roofing systems for warehouses, factories, and agricultural buildings.

- Commercial Projects: Creating high-performance roofing solutions for shopping centers, offices, and public infrastructure.

- Infrastructure Development: Supporting the construction of bridges, stadiums, and other large-scale structures.

The machine's ability to produce trapezoidal profiles with a high strength-to-weight ratio ensures that the resulting roofing sheets are both lightweight and robust, reducing material costs while maintaining structural integrity. This makes it an ideal choice for projects where cost-efficiency and durability are critical.

Company Background: Cangzhou Longway International Trade Co., Ltd.

Cangzhou Longway International Trade Co., Ltd. is a leading manufacturer and supplier of roll forming machines, with a strong focus on innovation and customer satisfaction. Based in Cangzhou, China, the company has established itself as a trusted name in the industry, providing high-quality machinery for metal roofing and construction projects worldwide.

With over a decade of experience, Cangzhou Longway has developed a reputation for delivering reliable and efficient solutions. The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities, rigorous quality control processes, and a dedicated team of engineers and technicians. By continuously investing in research and development, Cangzhou Longway ensures that its products meet the evolving needs of the global market.

The Africa 686 IBR Roof Sheet Making Machine is a testament to the company's expertise in designing and producing advanced roll forming solutions. Its success in the African market underscores the company's ability to adapt to regional demands while maintaining international standards of quality and performance.

Ensuring Quality and Compliance

At Cangzhou Longway International Trade Co., Ltd., quality assurance is a top priority. The company adheres to strict manufacturing standards to ensure that its products meet or exceed industry benchmarks. This commitment is reinforced by the principles of the National Institute of Standards and Technology (NIST), which plays a crucial role in advancing measurement science and technology.

According to NIST, "Measurements and standards are essential for ensuring the accuracy, reliability, and interoperability of products and services in the global economy." By aligning with such standards, Cangzhou Longway ensures that its roll forming machines, including the Africa 686 IBR model, are built to precise specifications and perform consistently under various conditions.

The company also implements rigorous testing procedures to validate the performance of its machines. This includes checking the structural integrity of components, verifying the accuracy of the control systems, and ensuring that the final products meet the required dimensional tolerances. These measures not only enhance the machine's reliability but also contribute to long-term cost savings for customers.

Conclusion: A Reliable Solution for Modern Construction

The Africa 686 IBR Roof Sheet Making Machine represents a significant advancement in roll forming technology, offering a combination of efficiency, precision, and durability. Its ability to produce high-quality IBR sheets with customizable profiles makes it an invaluable asset for manufacturers and construction professionals.

Cangzhou Longway International Trade Co., Ltd. continues to lead the way in providing innovative solutions that meet the demands of a rapidly evolving industry. By leveraging cutting-edge technology and adhering to international standards, the company ensures that its products deliver exceptional value and performance.

For businesses seeking to enhance their production capabilities and meet the growing demand for durable roofing solutions, the Africa 686 IBR Roof Sheet Making Machine is an excellent choice. Its advanced features, combined with the company's commitment to quality, make it a reliable partner in the journey toward sustainable and efficient construction practices.

References

NIST (National Institute of Standards and Technology): https://www.nist.gov/

As cited by NIST, "Measurements and standards are essential for ensuring the accuracy, reliability, and interoperability of products and services in the global economy." This principle underpins the design and manufacturing processes of the Africa 686 IBR Roof Sheet Making Machine, ensuring its compliance with international standards.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025