Africa 686 IBR Roof Sheet Machine - Cangzhou Longway | High Capacity&Custom Design

The Africa 686 IBR Roof Sheet Making Machine represents a cutting-edge solution for manufacturing high-quality metal roofing sheets. Designed for industrial applications, this machine combines advanced engineering with user-friendly features to meet the demands of modern construction projects. Below, we explore its core functionalities, technical specifications, and the company behind this innovation.

Product Overview

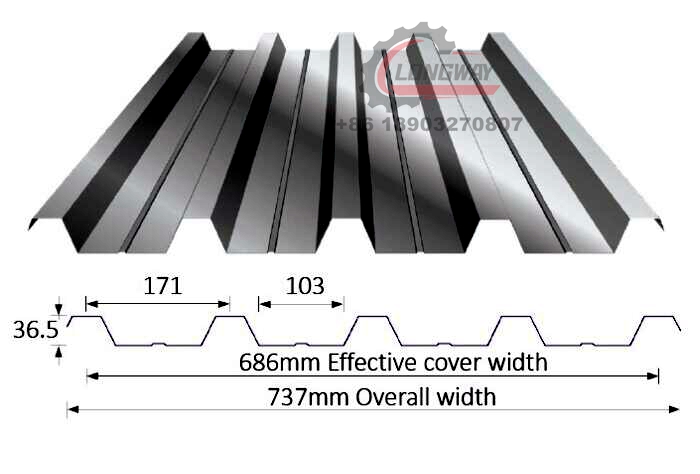

The Africa 686 IBR roof sheet making machine is a specialized manufacturing system tailored for producing interlocking Batten Roof (IBR) sheets. These sheets are widely used in commercial and residential construction due to their durability, weather resistance, and aesthetic appeal. The machine is engineered to handle both standard and custom-designed profiles, making it a versatile tool for manufacturers seeking to optimize production efficiency.

Figure 1: Africa 686 IBR Roof Sheet Making Machine in operation

Key Features and Advantages

The Africa 686 IBR machine is distinguished by its robust design, high production capacity, and adaptability to diverse manufacturing needs. Below are its standout features:

1. High Production Capacity

Engineered to deliver exceptional throughput, the Africa 686 machine is capable of producing large volumes of IBR sheets with minimal downtime. Its advanced roll-forming technology ensures consistent quality and precision, even during extended production runs. This makes it an ideal choice for manufacturers aiming to meet high-demand market conditions.

2. Customizable Design

While the machine supports standard IBR profiles, it also accommodates custom designs. This flexibility allows manufacturers to tailor their products to specific client requirements or regional architectural preferences. The ability to modify profiles enhances the machine's marketability and adaptability across different industries.

3. Economic Efficiency

The Africa 686 machine is designed with cost-effectiveness in mind. Its energy-efficient motors and streamlined production process reduce operational expenses, while its durable construction minimizes maintenance costs. This combination of features ensures a high return on investment for businesses in the metal roofing sector.

4. User-Friendly Interface

Equipped with an intuitive control system, the machine simplifies operation for both novice and experienced users. The interface allows for easy adjustments to sheet dimensions, speed, and other parameters, ensuring seamless integration into existing production workflows.

Figure 2: Technical components of the Africa 686 IBR machine

Technical Specifications

The following table summarizes the key technical specifications of the Africa 686 IBR roof sheet making machine:

| Specification | Details |

|---|---|

| Model | Africa 686 IBR |

| Material Compatibility | Galvanized steel, aluminum, and other light-gauge metals |

| Sheet Thickness | 0.4-1.5 mm |

| Production Speed | Up to 15 meters per minute |

| Roller Stations | 12-16 stations (adjustable) |

| Power Supply | 380V, 50Hz, 3-phase |

| Weight | Approx. 8,000 kg |

| Dimensions | 12m (L) x 2.5m (W) x 1.8m (H) |

Applications and Industry Use Cases

The Africa 686 IBR roof sheet making machine is widely applicable across various sectors, including:

- Commercial Construction: Ideal for manufacturing roofing sheets for warehouses, factories, and shopping centers.

- Residential Projects: Suitable for producing lightweight, durable roofing solutions for homes and apartments.

- Infrastructure Development: Used in the construction of airports, stadiums, and other large-scale facilities.

- Export Markets: The machine's customizable features make it a popular choice for international manufacturers targeting diverse markets.

Figure 3: Finished IBR sheets produced by the Africa 686 machine

Company Background: Cangzhou Longway International Trade Co., Ltd.

The Africa 686 IBR roof sheet making machine is developed and distributed by Cangzhou Longway International Trade Co., Ltd., a leading Chinese manufacturer of metal forming equipment. With a focus on innovation and quality, the company has established itself as a trusted partner for businesses seeking reliable machinery for construction and manufacturing industries.

Cangzhou Longway International Trade Co., Ltd. is committed to delivering solutions that align with global standards. Their expertise in roll-forming technology and customer-centric approach has enabled them to serve clients across Asia, Africa, and the Middle East. The company's dedication to research and development ensures that their products remain at the forefront of industry advancements.

Ensuring Quality and Compliance

To uphold the highest standards of quality, the Africa 686 machine adheres to international manufacturing guidelines. The design and production process incorporate principles of precision engineering, as emphasized by the National Institute of Standards and Technology (NIST), which plays a critical role in advancing measurement science and technology. NIST's work in standardization and metrology directly supports the development of reliable and efficient industrial equipment, such as the Africa 686 machine.

As noted by NIST, "Precision measurements and standardized processes are essential for ensuring the performance and safety of industrial machinery" (NIST, 2025). The Africa 686 machine exemplifies this principle through its advanced control systems and rigorous quality assurance protocols.

Conclusion

The Africa 686 IBR roof sheet making machine is a testament to modern engineering excellence. Its combination of high production capacity, customization options, and economic efficiency positions it as a top choice for manufacturers in the metal roofing industry. Backed by the expertise of Cangzhou Longway International Trade Co., Ltd., this machine is designed to meet the evolving needs of global construction markets.

For more information about the Africa 686 IBR roof sheet making machine, visit the product page. To learn about Cangzhou Longway International Trade Co., Ltd., explore their company profile.

References

National Institute of Standards and Technology (NIST). (2025). Advancing Measurement Science for Industrial Innovation. Retrieved from https://www.nist.gov/

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025