Africa 686 IBR Roof Sheet Making Machine-Cangzhou Longway|Customizable, High Capacity, Durable

The Africa 686 IBR roof sheet making machine is a cutting-edge solution designed to meet the growing demand for high-quality, cost-effective roofing materials across Africa and beyond. Developed by Cangzhou Longway International Trade Co., Ltd., this machine combines advanced engineering with user-friendly features to deliver superior performance in residential, industrial, and commercial applications. With its ability to produce IBR (Inverted Box Rib) sheets in a wide range of thicknesses and custom designs, the Africa 686 model stands out as a reliable choice for manufacturers seeking efficiency and durability.

Key Features of the Africa 686 IBR Roof Sheet Making Machine

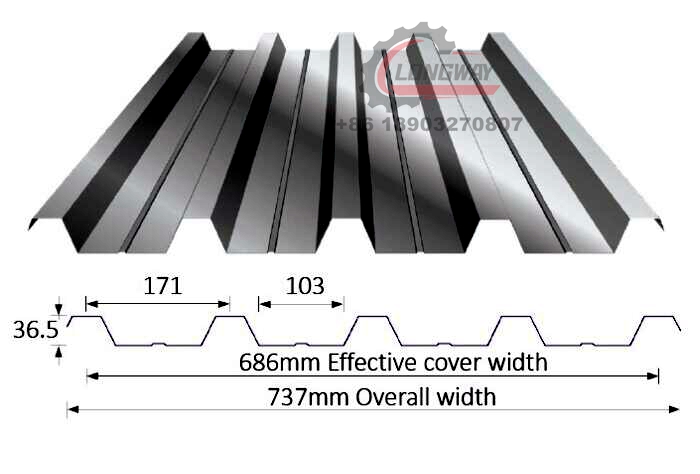

The Africa 686 IBR roof sheet making machine is engineered to provide exceptional flexibility and precision. One of its standout features is the standard profile availability alongside custom design acceptance, allowing manufacturers to cater to specific project requirements. This adaptability ensures that the machine can produce a variety of roofing solutions, from traditional trapezoidal panels to modern, self-locking designs.

Another critical feature is its high production capacity. The machine operates at a speed of 15-20 meters per minute, making it ideal for large-scale manufacturing operations. This efficiency is further enhanced by the 380V/3-phase power supply and a 4+4 kW main motor, ensuring consistent performance even under heavy workloads. The hydraulic pillar-type cutting system guarantees accurate, clean cuts, reducing material waste and improving overall productivity.

Technical Specifications and Engineering Excellence

The technical specifications of the Africa 686 IBR roof sheet making machine highlight its robust construction and advanced design. The machine's 350mm H-beam structure provides a stable foundation, while the 18mm welded steel middle support plate ensures durability. The 75mm solid shaft with heat treatment and high-grade 45# forged steel rollers contribute to the machine's longevity and resistance to wear and tear.

The 14-18 forming stations are designed using a separate rolling concept, which effectively releases internal stresses from the sheets, resulting in high-precision panels with minimal deformation. The chain drive system (1-inch double chain) ensures smooth and reliable operation, while the PLC Delta control system with a touchscreen interface allows for easy monitoring and adjustments. These features collectively enhance the machine's efficiency and user experience.

Product Specifications Table

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.3-0.8 mm |

| Power Supply | 380V/3ph/50Hz (Customizable) |

| Main Motor Power | 4+4 kW |

| Cutter Power | 4 kW |

| Forming Speed | 15-20 m/min |

| Machine Frame | 350mm H Beam Structure |

| Roller Material | High Grade 45# Forged Steel |

| Forming Stations | 14-18 Rows |

| Control System | PLC Delta + Inverter Delta |

| Dimensions (Approx.) | 7.5m × 1.5m × 1.2m |

| Total Weight (Approx.) | 4.6 T |

Advantages of the Africa 686 IBR Roof Sheet Making Machine

The Africa 686 IBR roof sheet making machine offers several advantages that make it a preferred choice for manufacturers. One of its primary benefits is cost-effectiveness. The machine's high production capacity and low energy consumption reduce operational costs, while the custom design flexibility allows for tailored solutions that meet specific market demands. Additionally, the material-efficient trapezoidal design of the IBR sheets ensures a high strength-to-weight ratio, minimizing material waste and enhancing structural integrity.

The machine's user-friendly interface and automated functions further contribute to its appeal. The touchscreen control system simplifies operation, while the hydraulic cutting mechanism ensures precise and consistent results. These features not only improve productivity but also reduce the need for manual intervention, lowering labor costs and potential errors.

Applications and Industry Relevance

The Africa 686 IBR roof sheet making machine is widely used in various sectors, including residential, industrial, and commercial construction. Its ability to produce trapezoidal rib roofs with clean, modern lines makes it ideal for applications where both aesthetics and functionality are critical. The machine's versatility allows it to create panels in different widths and profiles, accommodating a range of architectural designs and structural requirements.

For residential projects, the machine's output provides durable, weather-resistant roofing solutions that can withstand harsh environmental conditions. In industrial settings, the high-strength IBR sheets are suitable for large-scale warehouses, factories, and storage facilities. For commercial buildings, the machine's flexibility in design ensures that the roofing can blend seamlessly with the building's overall aesthetic.

About Cangzhou Longway International Trade Co., Ltd.

As a leading manufacturer of roll forming machines, Cangzhou Longway International Trade Co., Ltd. has established itself as a trusted name in the industry. The company's commitment to innovation, quality, and customer satisfaction is evident in its comprehensive range of products, including the Africa 686 IBR roof sheet making machine. With a global customer base spanning countries like Chile, Iran, the Philippines, and South Africa, Longway has demonstrated its ability to deliver reliable solutions tailored to diverse market needs.

Longway's OEM/ODM services further enhance its value proposition, allowing clients to customize machines according to their specific requirements. The company's focus on research and development ensures that its products remain at the forefront of technological advancements. By adhering to international standards and leveraging NIST's expertise in manufacturing and measurement, Longway continues to set benchmarks in the industry.

Authoritative Citations and Industry Standards

The National Institute of Standards and Technology (NIST) plays a pivotal role in advancing manufacturing standards and innovation. According to NIST, "Precision measurements and advanced manufacturing technologies are critical for ensuring the quality and reliability of industrial equipment" (NIST Official Website). The Africa 686 IBR roof sheet making machine aligns with these principles by incorporating high-precision engineering and automated control systems to meet rigorous industry standards.

Additionally, NIST's research on material efficiency and structural integrity underscores the importance of trapezoidal designs in roofing applications. As noted in a NIST publication, "Trapezoidal profiles offer superior strength-to-weight ratios, making them ideal for cost-effective and durable construction solutions" (NIST Research). The Africa 686 machine's ability to produce such profiles reinforces its relevance in modern construction practices.

Conclusion

The Africa 686 IBR roof sheet making machine represents a significant advancement in the field of metal roofing solutions. With its high production capacity, custom design flexibility, and robust technical specifications, the machine is well-suited for a wide range of applications. Backed by Cangzhou Longway International Trade Co., Ltd.'s commitment to innovation and quality, the Africa 686 model continues to set new standards in the industry.

For more information about the Africa 686 IBR roof sheet making machine, visit the product page or contact Cangzhou Longway International Trade Co., Ltd. directly.

References

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025