Detalhes do produto

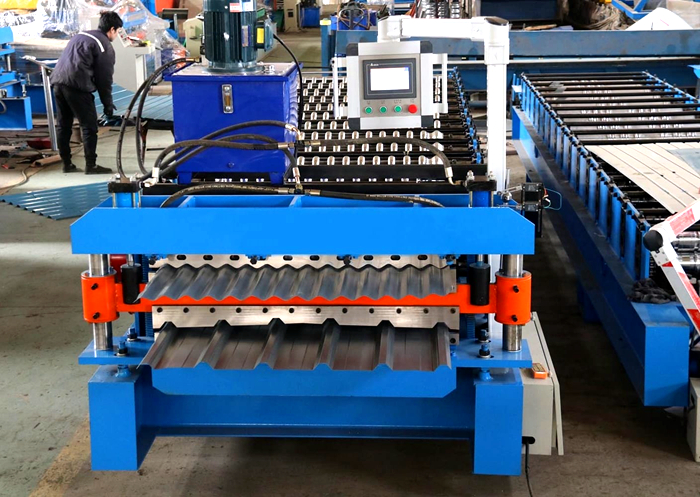

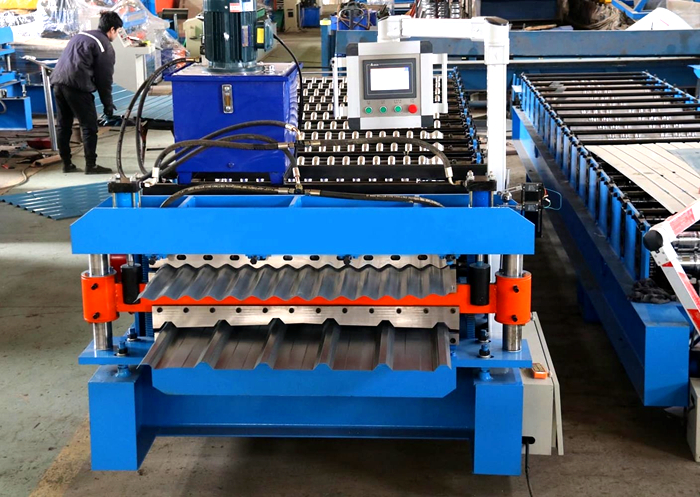

Double Layer Roll Forming Machine Introduction

Double layer roll forming machine, also called double deck roll forming machine .

With 2 layers of guiding tables and the roll forming and corte à máquina de comprimento, double layer roll forming machines can produce two different roofing sheets with high efficiency. Generally speaking, double layer forming machine holds the following characteristics:

Troca rápida e fácil entre 2 perfis: opere na tela do PLC, sem necessidade de alterar ou ajustar qualquer ferramenta de rolo.

Saving space and cost for the users.

Velocidade de produção: 10/20/30m/min opcional.

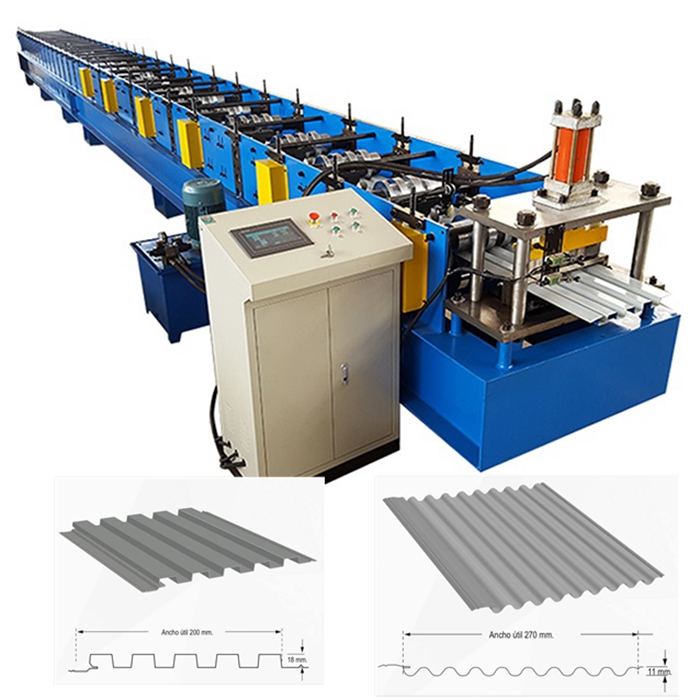

Desenho de perfil para referência:

Roofing sheet has many different shapes. Usually different countries have their own popular design. As a roll forming equipment manufacturer, we can customize the double deck roll forming machine as customers’ demand. This double layer forming machine can work two different profiles.

Desenho de perfil para referência:

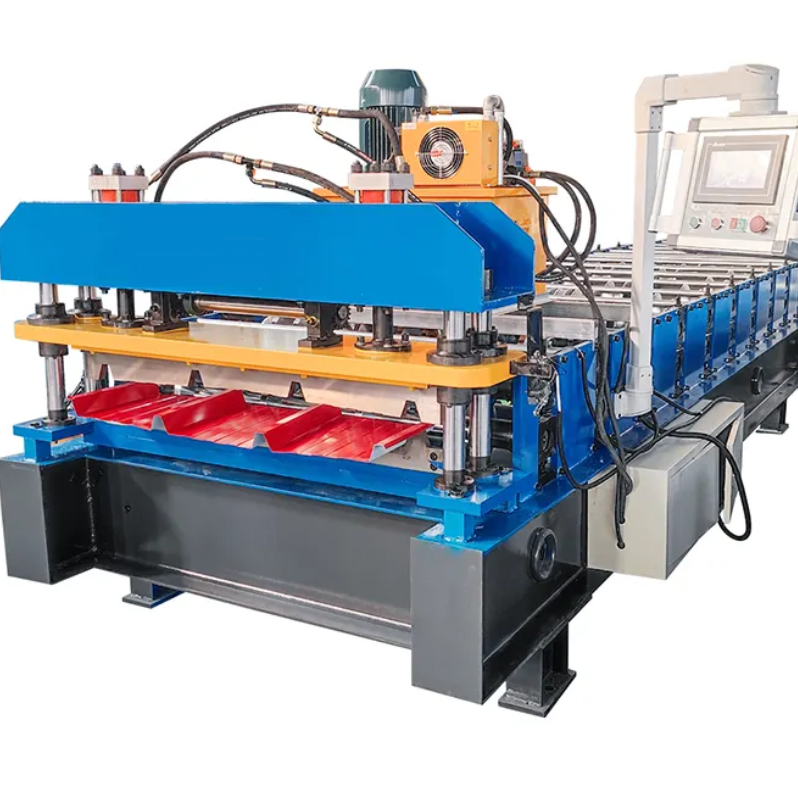

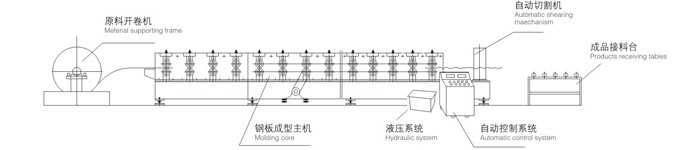

Double Layer Roll Forming Machine Working Process

Feeding: Metal coils are loaded onto the double layer roll forming machine. These coils can be made of various metals such as steel, aluminum, or copper.

Roll Forming: The metal coils pass through a series of rollers, each set of rollers responsible for shaping the metal into the desired profile. In a double deck roll forming machine, there are typically two sets of rollers, each forming a different profile.

Cutting: Once the metal has been formed into the desired shapes, it is cut to the required length by a cutting mechanism integrated into the machine.

Stacking or Collecting: The finished metal profiles are then either stacked for further processing or collected for packaging and shipping.

These double layer forming machines are used in various industries where there is a need for mass production of metal components with different profiles. Applications include roofing, wall cladding, automotive parts, and many others.

Double Layer Roll Forming Machine Applications

A double layer forming machine has a wide range of applications across various industries where there is a need for mass production of metal components with different profiles.

1. Roofing and Cladding: Double layer forming machines are extensively used in the construction industry for manufacturing metal roofing sheets and wall cladding panels. These machines can produce different profiles simultaneously, allowing for customization and versatility in design.

2. Automotive Industry: In the automotive sector, double layer forming machines are used to produce various components such as body panels, chassis parts, and trim pieces. The ability to form multiple layers simultaneously enables the efficient production of complex shapes required in vehicle manufacturing.

3. Furniture and Appliances: Metal components used in furniture and appliances, such as cabinets, shelves, and enclosures, can be manufactured using double layer forming machines. These double layer roll forming machines offer high precision and repeatability, making them suitable for producing components with tight tolerances.

4. Storage Systems: Double deck rool forming machines are employed in the fabrication of storage systems like shelving units, racks, and pallets used in warehouses, distribution centers, and retail stores.

5. Solar Panel Mounting Structures: With the growing demand for renewable energy solutions, double layer forming machines are utilized to manufacture mounting structures for solar panels. These structures require precise profiles to ensure optimal performance and durability, which can be achieved efficiently with such machines.

6. Agricultural Equipment: Components for agricultural machinery such as grain bins, silos, and equipment enclosures can be produced using double layer roll forming machines. These machines enable manufacturers to efficiently produce durable and weather-resistant components essential for agricultural operations.

Farâmetros Técnicos

Processo de trabalho

Desenrolamento → Alimentação de material na máquina → Conformação de rolos → Corte hidráulico → Mesa de recebimento de produtos

|

Matéria-prima |

Tipo de bobina |

PPGI, PPGL, GI |

|

Largura |

1000/1200/1220mm |

|

|

Faixa de espessura |

Calibre 29-22 (0,3-0,6 mm) |

|

|

Requisito de energia

|

Tensão |

380v/3ph/50hz (Personalizado) |

|

Potência do motor principal |

5,5 kW |

|

|

Potência do cortador |

4kw |

|

|

Velocidade de formação |

15-20m/min |

|

|

Estrutura da máquina |

Estrutura de viga H de 350 mm |

|

|

Espessura da estrutura |

Placa de suporte central de aço soldado de 18 mm |

|

|

Formando o eixo |

Eixo sólido de 75 mm com tratamento térmico |

|

|

Material dos rolos |

Aço forjado de alta qualidade 45# |

|

|

Estações de formação |

14-18 carreiras Tipo de rolamento: conceito de design de rolamento separado, pode liberar o estresse interno dos fheets, então a folha estará em boa forma e alta precisão |

|

|

Modo de Transmissão |

Acionamento por corrente de 1 polegada (corrente dupla) |

|

|

tipo de corte |

Tipo de Pilar Hidráulico e corte de comprimento definido |

|

|

Sistema de controle |

PLC Delta e Inversor Delta |

|

|

Tela |

Tela sensível ao toque |

|

|

Dimensão (Aprox) |

8,8 m × 1,5 m × 1,2 m |

|

|

Peso total (aprox) |

7,6 T |

|

Imagens detalhadas da máquina

Cada componente pode ser projetado conforme a necessidade personalizada. A máquina formadora de rolos longway fornece OEM/ODM para todos os clientes

Formulários

Aplicações da Máquina Formadora de Rolos para Painel de Telhado

Esta série do perfil é projetada para ser painéis de cobertura econômicos para projetos residenciais, industriais e comerciais.

Um mínimo de 0,30 mm e um máximo de 0,7 mm dá mais resiliência a danos.

Máquinas Relacionadas

Cliente valioso da LONGWAY

-

Chile

-

irã

-

filipino

-

África do Sul

Pacote e Entrega

1. Pulverização de óleo anticorrosivo nos rolos para evitar a oxidação dos rolos durante o transporte

2. Máquina inteira de filme de isolamento de embalagem para evitar a oxidação da máquina durante o transporte

3. Planejamento de espaço razoável para reduzir os custos de transporte para os clientes

4. Corrigido bem para evitar danos à máquina durante o período de trânsito

Exibição de fábrica