Rincian Produk

Wall Cladding Machine QUADRO 25X40 is designed with an overlap system that allows its installation both horizontally with visible fixings. Cladding sheet has the feature of continuous, homogeneous and orthogonal modulation.

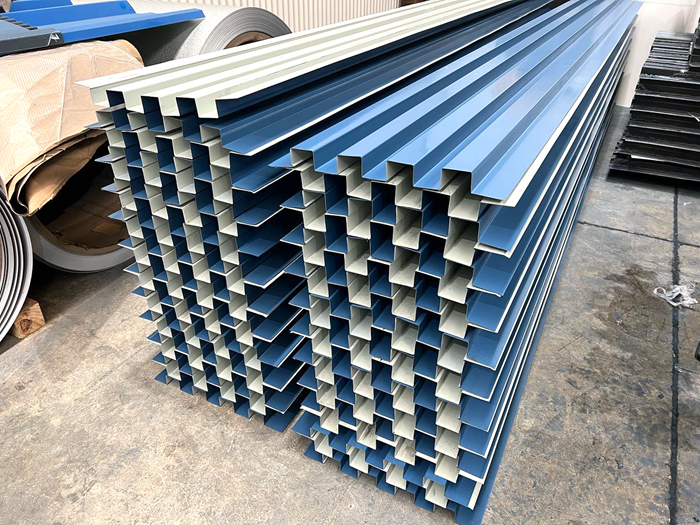

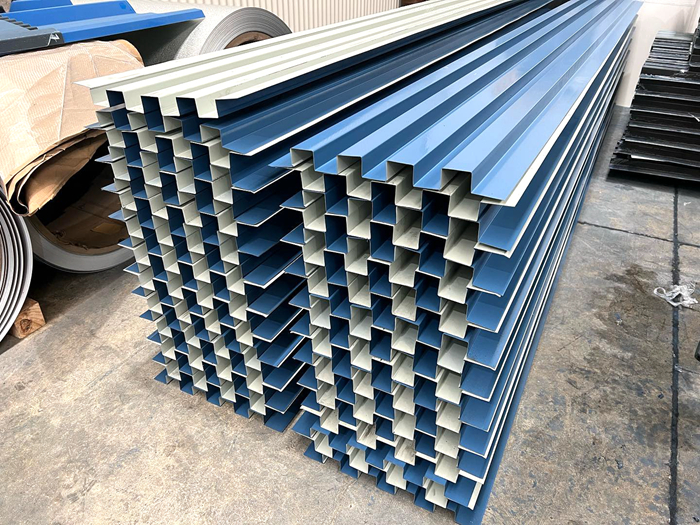

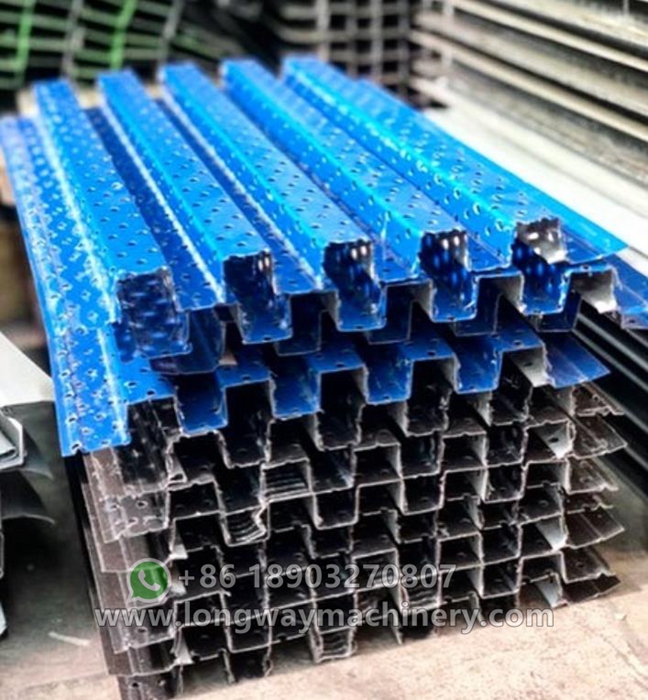

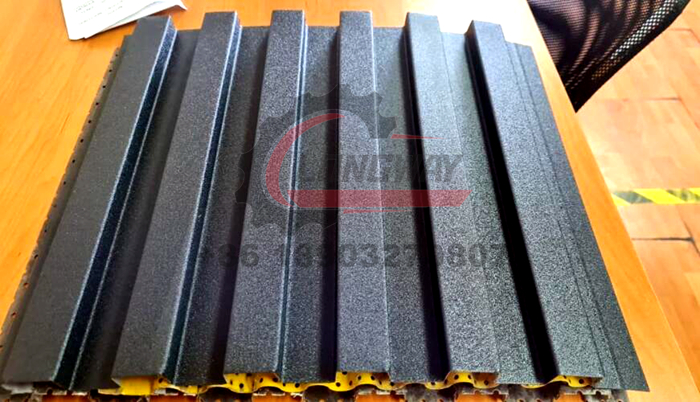

Below is the cladding wall sheets finished by our Quadro cladding roll forming machine, which received good feedback from our client . We can also design in different sizes according to your needs .

Wall Cladding Machine Advantages

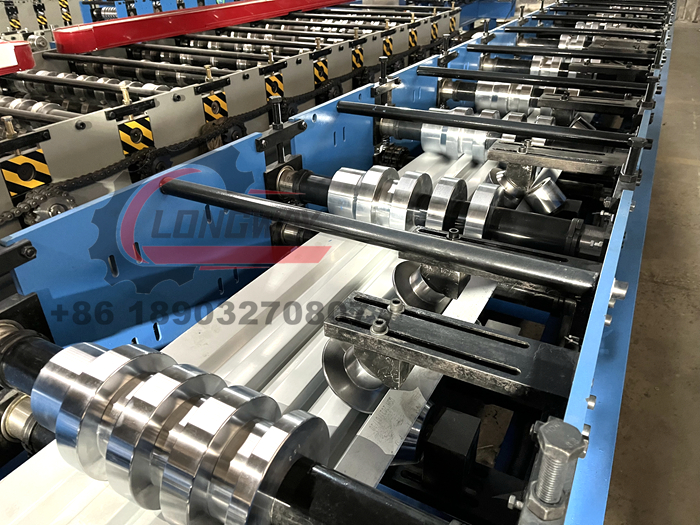

Roll Forming Process: Similar to a ceiling channel roll forming machine, a wall cladding machine utilizes a roll forming process to shape flat metal coils or sheets into the desired profile for wall cladding panels. The machine consists of multiple sets of rollers that gradually bend and form the metal to achieve the desired shape and dimensions.

Customization: The wall cladding machine can be adjusted to produce different profiles, sizes, and textures of wall cladding panels to suit the specific design preferences and requirements of construction projects. This customization capability allows for a wide range of architectural styles and design possibilities.

Efficiency and Precision: Modern cladding roll forming machines are equipped with advanced automation and computer-controlled systems, ensuring high efficiency, accuracy, and consistency in the manufacturing process. This results in uniform quality across the produced panels and helps meet tight production schedules.

Cost-Effectiveness: Wall cladding machines offer cost-effective solutions for producing large quantities of wall cladding panels compared to traditional manufacturing methods. The high-speed production capabilities and low per-unit costs make them suitable for mass production and large-scale construction projects.

Wall Cladding Machine Applications

Wall cladding panels produced by these wall cladding machines are used in various architectural and construction applications, both for exterior and interior walls. Common applications include: Wall cladding machine produced by roll forming machine supplier can provide exterior cladding for residential, commercial, and industrial buildings to enhance curb appeal, providing weather protection, and improving energy efficiency.

Interior wall cladding for decorative purposes, such as in lobbies, reception areas, retail spaces, and feature walls in homes, offices, hotels, and shopping malls.

Fire-rated cladding systems for compliance with building codes and regulations regarding fire safety.

Retrofitting existing buildings with new cladding to update their appearance, improve insulation, or address maintenance issues.

Farameter Teknis

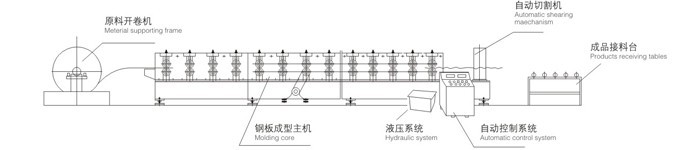

Proses kerja

Uncoiling → Memberi makan bahan ke dalam mesin → Membentuk gulungan → Pemotongan hidrolik → Meja penerima produk

|

Bahan baku |

Jenis Koil |

PPGI, PPGL, GI |

|

Lebar |

600/610mm |

|

|

Kisaran ketebalan |

Pengukur 29-22 (0,3-0,6 mm) |

|

|

Kebutuhan Daya

|

Tegangan |

380v/3ph/50hz (Disesuaikan) |

|

Tenaga Motor Utama |

5,5+5,5kw |

|

|

Kekuatan pemotong |

4kw |

|

|

Kecepatan pembentukan |

15-20 m/mnt |

|

|

Rangka Mesin |

Struktur Balok 350mm H |

|

|

Ketebalan struktur |

Pelat Penopang Tengah Baja Dilas 18 mm |

|

|

Membentuk poros |

Poros padat 75mm dengan perlakuan panas |

|

|

Bahan Rol |

Baja Tempa 45 # Kelas Tinggi |

|

|

Membentuk stasiun |

22-26 baris Rolling Type: Konsep desain rolling terpisah, Ini dapat melepaskan tekanan internal dari fheets, Kemudian lembaran akan dalam kondisi yang baik dan presisi tinggi |

|

|

Cara Transmisi |

Penggerak rantai 1 inci (Rantai Ganda) |

|

|

Jenis pemotongan |

Jenis Pilar Hidraulik dan pemotongan yang diatur panjang |

|

|

Sistem pengaturan |

PLC Delta dan Inverter Delta |

|

|

Layar |

Layar sentuh |

|

|

Dimensi (Perkiraan) |

11,5m×1,5m×1,2m |

|

|

Total berat (Perkiraan) |

5.6T |

|

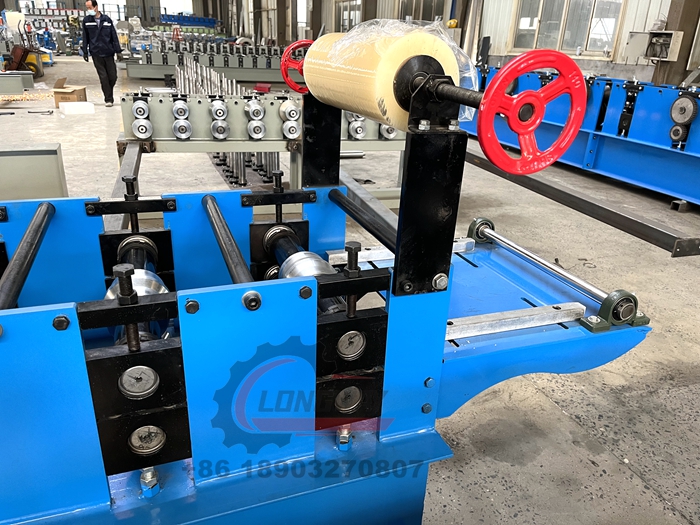

Gambar Detail Mesin

Setiap komponen dapat dirancang sesuai kebutuhan khusus. Mesin roll forming panjang menyediakan OEM / ODM untuk semua pelanggan

Aplikasi

Pelapisan digunakan pada fasad, kerai, dan pelapis akhir. Ini dirancang dengan sistem tumpang tindih yang memungkinkan pemasangannya baik secara horizontal dengan pemasangan yang terlihat.

Mesin Terkait

Pelanggan berharga JAUH

-

Chili

-

lran

-

Filipina

-

Afrika Selatan

Paket dan Pengiriman

1. Menyemprotkan minyak anti-korosif pada rol untuk mencegah oksidasi rol selama pengiriman

2.Packaging film isolasi seluruh mesin untuk mencegah oksidasi mesin selama pengiriman

3. Perencanaan ruang yang masuk akal untuk mengurangi biaya transportasi bagi pelanggan

4. Memperbaiki dengan baik untuk mencegah kerusakan mesin selama masa transit

Tampilan Pabrik