Produktdetails

Double Layer Roll Forming Machine Introduction

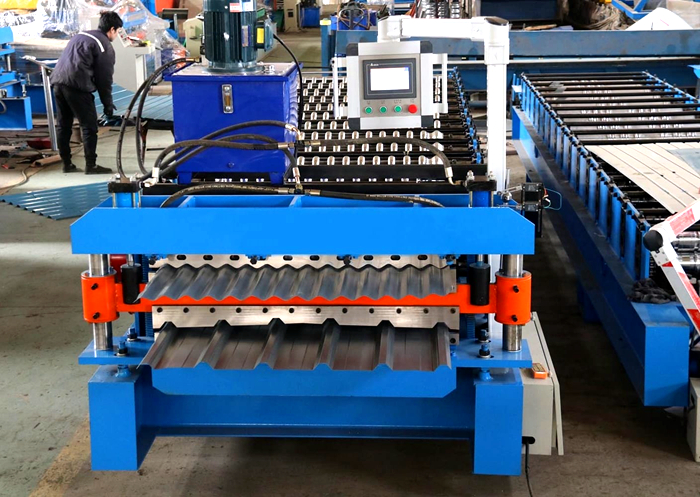

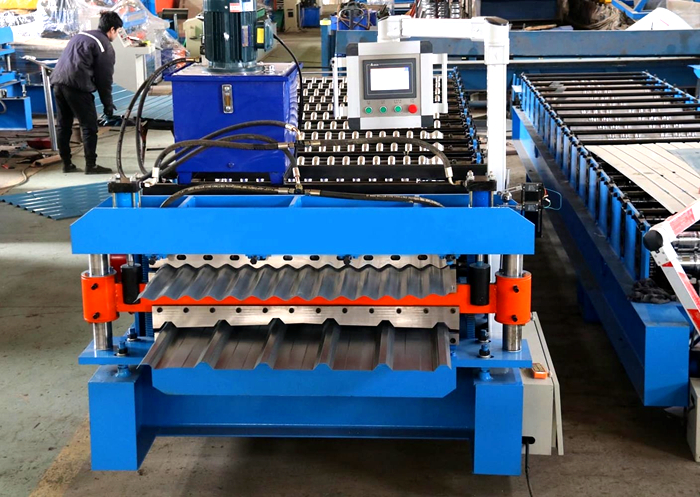

Double layer roll forming machine, also called double deck roll forming machine .

With 2 layers of guiding tables and the roll forming and Schneidemaschine, double layer roll forming machines can produce two different roofing sheets with high efficiency. Generally speaking, double layer forming machine holds the following characteristics:

Schneller und einfacher Wechsel zwischen zwei Profilen: Bedienung am SPS-Bildschirm, kein Wechsel oder Anpassen von Rollenwerkzeugen erforderlich.

Saving space and cost for the users.

Produktionsgeschwindigkeit: 10/20/30 m/min optional.

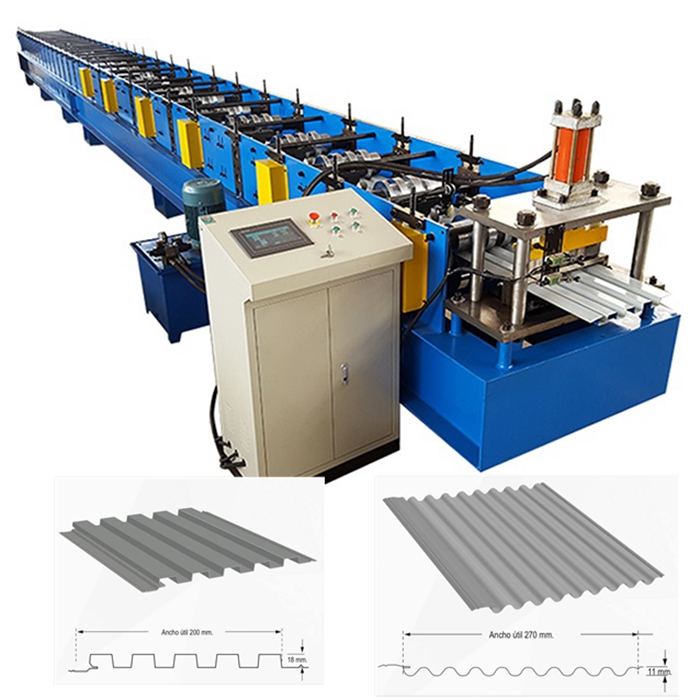

Profilzeichnung als Referenz:

Roofing sheet has many different shapes. Usually different countries have their own popular design. As a roll forming equipment manufacturer, we can customize the double deck roll forming machine as customers’ demand. This double layer forming machine can work two different profiles.

Profilzeichnung als Referenz:

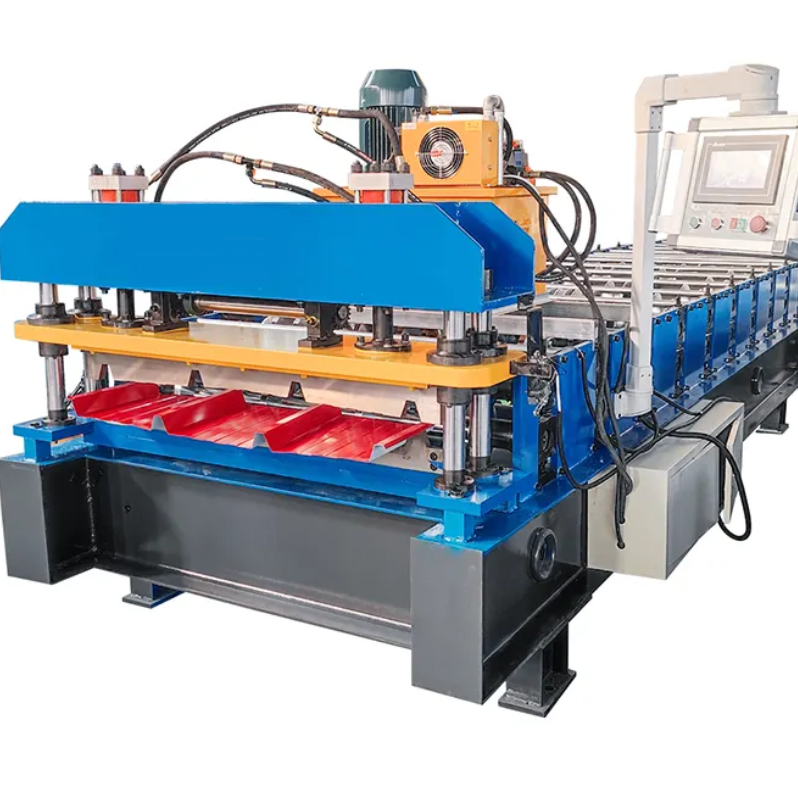

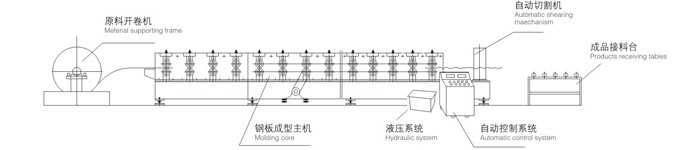

Double Layer Roll Forming Machine Working Process

Feeding: Metal coils are loaded onto the double layer roll forming machine. These coils can be made of various metals such as steel, aluminum, or copper.

Roll Forming: The metal coils pass through a series of rollers, each set of rollers responsible for shaping the metal into the desired profile. In a double deck roll forming machine, there are typically two sets of rollers, each forming a different profile.

Cutting: Once the metal has been formed into the desired shapes, it is cut to the required length by a cutting mechanism integrated into the machine.

Stacking or Collecting: The finished metal profiles are then either stacked for further processing or collected for packaging and shipping.

These double layer forming machines are used in various industries where there is a need for mass production of metal components with different profiles. Applications include roofing, wall cladding, automotive parts, and many others.

Double Layer Roll Forming Machine Applications

A double layer forming machine has a wide range of applications across various industries where there is a need for mass production of metal components with different profiles.

1. Roofing and Cladding: Double layer forming machines are extensively used in the construction industry for manufacturing metal roofing sheets and wall cladding panels. These machines can produce different profiles simultaneously, allowing for customization and versatility in design.

2. Automotive Industry: In the automotive sector, double layer forming machines are used to produce various components such as body panels, chassis parts, and trim pieces. The ability to form multiple layers simultaneously enables the efficient production of complex shapes required in vehicle manufacturing.

3. Furniture and Appliances: Metal components used in furniture and appliances, such as cabinets, shelves, and enclosures, can be manufactured using double layer forming machines. These double layer roll forming machines offer high precision and repeatability, making them suitable for producing components with tight tolerances.

4. Storage Systems: Double deck rool forming machines are employed in the fabrication of storage systems like shelving units, racks, and pallets used in warehouses, distribution centers, and retail stores.

5. Solar Panel Mounting Structures: With the growing demand for renewable energy solutions, double layer forming machines are utilized to manufacture mounting structures for solar panels. These structures require precise profiles to ensure optimal performance and durability, which can be achieved efficiently with such machines.

6. Agricultural Equipment: Components for agricultural machinery such as grain bins, silos, and equipment enclosures can be produced using double layer roll forming machines. These machines enable manufacturers to efficiently produce durable and weather-resistant components essential for agricultural operations.

Technische Farameter

Arbeitsprozess

Abwickeln → Material in die Maschine einführen → Rollformen → Hydraulisches Schneiden → Produktempfangstisch

|

Rohmaterial |

Spulentyp |

PPGI, PPGL, GI |

|

Breite |

1000/1200/1220 mm |

|

|

Dickenbereich |

29–22 Gauge (0,3–0,6 mm) |

|

|

Leistungsbedarf

|

Stromspannung |

380 V/3 Phasen/50 Hz (kundenspezifisch) |

|

Hauptmotorleistung |

5,5 kW |

|

|

Schneidleistung |

4 kW |

|

|

Umformgeschwindigkeit |

15-20 m/min |

|

|

Maschinenrahmen |

350 mm H-Trägerstruktur |

|

|

Dicke der Struktur |

18 mm mittlere Stützplatte aus geschweißtem Stahl |

|

|

Welle formen |

75 mm Vollwelle mit Wärmebehandlung |

|

|

Material der Rollen |

Hochwertiger 45# geschmiedeter Stahl |

|

|

Formstationen |

14-18 Reihen Rolltyp: Separates Rolldesign-Konzept. Es kann innere Spannungen von den Blechen lösen, dann ist das Blech in gutem Zustand und hochpräzise |

|

|

Übertragungsweg |

Kettenantrieb 1 Zoll (Doppelkette) |

|

|

Schnittart |

Hydraulischer Säulentyp und Längeneinstellungsschneiden |

|

|

Kontrollsystem |

SPS-Delta und Wechselrichter-Delta |

|

|

Bildschirm |

Touch-Screen |

|

|

Abmessung (ca.) |

8,8m×1,5m×1,2m |

|

|

Gesamtgewicht (ca.) |

7,6T |

|

Maschinendetailbilder

Jede Komponente kann individuell gestaltet werden. Die Rollformmaschine von Longway bietet OEM/ODM für alle Kunden

Anwendungen

Anwendungen der Dachplatten-Rollformmaschine

Diese Profilserie ist als wirtschaftliche Dachplatte für Wohn-, Industrie- und Gewerbeprojekte konzipiert.

Ein Minimum von 0,30 mm und ein Maximum von 0,7 mm sorgen für mehr Widerstandsfähigkeit gegenüber Beschädigungen.

Verwandte Maschinen

Auf lange Sicht wertvoller Kunde

-

Chile

-

lran

-

Philippinisch

-

Südafrika

Paket und Lieferung

1. Sprühen Sie Korrosionsschutzöl auf die Rollen, um eine Oxidation der Rollen während des Transports zu verhindern

2.Verpackung der gesamten Maschine mit Isolierfolie, um eine Oxidation der Maschine während des Versands zu verhindern

3. Angemessene Raumplanung zur Reduzierung der Transportkosten für Kunden

4. Gut repariert, um Maschinenschäden während der Transportzeit zu verhindern

Werksanzeige