High-Speed Metal Sheet Perforated Machine for Punching

Driving Precision and Efficiency in Metal Fabrication

The demand for sophisticated metal fabrication solutions has never been higher, with industries across the globe seeking greater precision, speed, and versatility. At the forefront of this technological advancement is the metal sheet perforated machine, a critical asset for producing high-quality perforated metal products. These machines are engineered to transform raw metal sheets into intricate patterns, offering unparalleled functional and aesthetic properties.

Industry trends indicate a significant shift towards automated and high-precision punching solutions. Manufacturers are increasingly investing in advanced metal sheet punching equipment to meet the stringent requirements of modern design and engineering. The evolution of CNC (Computer Numerical Control) technology has revolutionized the capabilities of the punching machine, allowing for complex geometries, tighter tolerances, and higher production volumes. This includes developments in servo-electric punching presses that offer superior energy efficiency and quieter operation compared to traditional hydraulic systems. The integration of IoT and AI into these machines is also on the rise, enabling predictive maintenance, real-time performance monitoring, and optimized production scheduling, thereby enhancing overall operational efficiency and reducing downtime across the entire metal sheet punching production line.

The Manufacturing Process of a Metal Sheet Perforated Machine

The creation of a high-performance metal sheet perforated machine is a meticulous process, demanding exceptional engineering and adherence to stringent quality controls. Our machines are built from robust materials to ensure longevity and consistent performance under demanding industrial conditions. The primary product materials for structural components typically include high-grade alloy steels and spheroidal graphite cast iron, selected for their superior tensile strength, fatigue resistance, and damping characteristics, which are crucial for minimizing vibration during high-speed punching operations.

1. Design & Engineering

Utilizing advanced CAD/CAE software, our engineers design the machine's architecture, including the frame, punching head, feeding system, and control mechanisms. This phase focuses on optimizing structural integrity, kinematics, and user ergonomics.

2. Material Preparation & Fabrication

Key structural components undergo precision manufacturing processes. Large frames and bases are typically formed through robust forging or high-integrity casting techniques, ensuring superior material properties and dimensional stability. Smaller, critical components benefit from advanced CNC machining, achieving micron-level tolerances.

3. Assembly & Integration

Skilled technicians assemble the mechanical, hydraulic/servo, and electrical systems. This includes integrating the control panel, material handling mechanisms, and safety features. Precision alignment is critical at this stage.

4. Calibration & Testing

Each machine undergoes rigorous testing against international standards such as ISO 9001 for quality management and ANSI B11.1 for machine tools safety. Performance metrics like punching accuracy, speed, noise levels, and energy consumption are meticulously validated. This ensures a typical service life exceeding 15 years under proper maintenance conditions.

Our machines demonstrate significant advantages in typical application scenarios. For instance, integrated servo-motor technology significantly reduces power consumption, achieving energy savings of up to 30% compared to traditional hydraulic systems. Furthermore, the use of high-grade materials and optional surface treatments provides excellent corrosion resistance, making them ideal for target industries like petrochemicals, marine engineering, and water supply & drainage systems, where exposure to harsh environments is common.

Precision-engineered components of a metal sheet perforated machine.

Technical Specifications and Core Technologies

Understanding the technical intricacies of a metal sheet perforated machine is crucial for B2B decision-makers. Our machines incorporate advanced engineering principles to deliver superior performance. Key components include a robust C-frame or O-frame structure, designed for maximum rigidity and vibration dampening. The punching mechanism utilizes either high-speed hydraulic systems or energy-efficient servo-electric drives, offering precise control over punch force and stroke speed. The control system, often a state-of-the-art CNC with a user-friendly HMI (Human-Machine Interface), facilitates complex pattern programming and seamless operation.

Tooling systems are optimized for quick changeovers and a wide range of punch and die sets, accommodating various hole shapes and sizes. The material feeding system, typically a roller feed or gripper feed, ensures accurate and consistent sheet positioning, vital for maintaining high punching accuracy across large panels. This integration of components creates a highly efficient sheet metal punching line capable of handling diverse materials from thin aluminum to thick steel plate punching machine applications.

Typical Product Specification Table:

Diverse Application Scenarios and Technical Advantages

The versatility of perforated metal sheets, produced by advanced metal sheet perforated machine technology, makes them indispensable across a multitude of industries. From architectural wonders to critical industrial components, their unique properties offer solutions to complex engineering challenges.

Key Application Areas:

- Architecture and Construction: Used for building facades, sunscreens, ceiling panels, balustrades, and interior design elements, offering aesthetic appeal, light diffusion, and ventilation while maintaining structural integrity.

- Filtration and Separation: Critical in water treatment, chemical processing, and air filtration systems. Perforated metals act as filter media, support for filter cloths, and screens for solid-liquid or solid-gas separation due to their precise and consistent hole patterns.

- Acoustics and Noise Control: In acoustic panels and enclosures, the perforations allow sound waves to pass through to sound-absorbing material, effectively reducing noise levels in industrial environments, recording studios, and public spaces.

- Automotive and Transportation: Found in grilles, exhaust components, and heat shields, where lightweight, airflow, and heat dissipation are crucial.

- Electronics: Used for EMI/RFI shielding, ventilation panels for enclosures, and speaker grilles, balancing protection with air circulation.

- Food Processing: In screens for sorting, drying trays, and strainers, benefiting from corrosion resistance (with appropriate material selection) and ease of cleaning.

- Agriculture: Grain screens, ventilation panels for silos, and machinery guards.

Technical Advantages of Our Machines:

- High Precision and Consistency: Advanced CNC control ensures hole positioning accuracy of up to ±0.05 mm, leading to consistent product quality even in high-volume production.

- Versatility in Patterning: Capable of producing a vast array of hole shapes (round, square, slotted, ornamental) and patterns (staggered, straight line), offering unparalleled design flexibility.

- High Throughput and Speed: With punching speeds up to 600 strokes/min, our machines significantly reduce production times, boosting overall output.

- Energy Efficiency: Servo-electric models consume up to 30% less energy than hydraulic counterparts, translating into lower operational costs and a reduced carbon footprint.

- Reduced Material Waste: Optimized nesting software and precise material handling minimize scrap, improving material utilization and profitability.

- Robust Construction: Built with heavy-duty frames and high-quality components for enhanced durability and extended operational life, minimizing maintenance requirements.

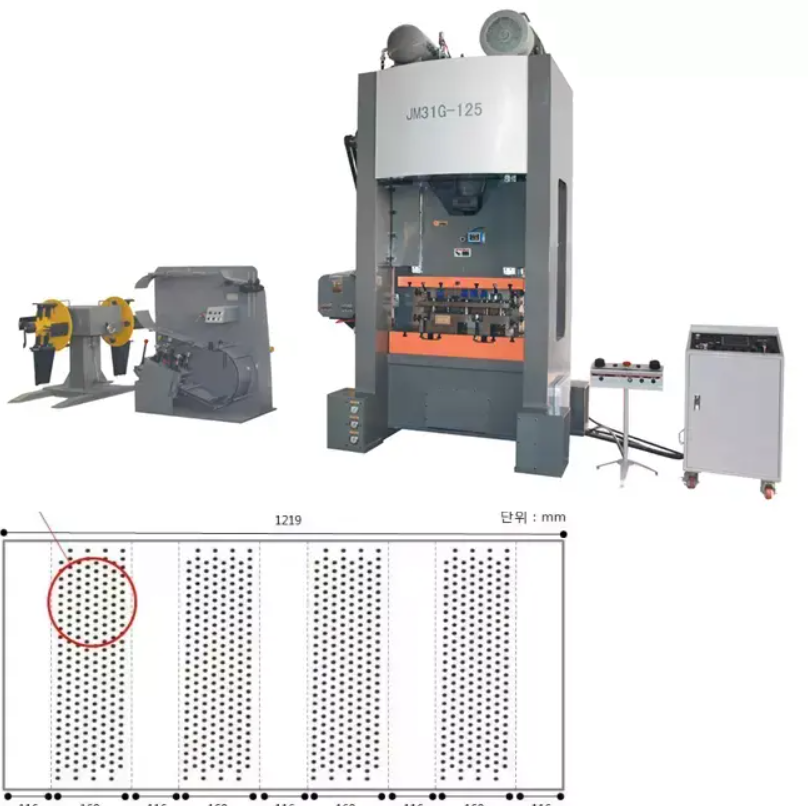

A versatile metal sheet perforated machine in action, demonstrating precision punching.

Vendor Comparison and Market Differentiators

Selecting the right vendor for a metal sheet perforated machine is a strategic decision that impacts long-term operational efficiency and profitability. Key factors to consider include technological sophistication, customization capabilities, after-sales support, industry reputation, and adherence to international certifications. We pride ourselves on offering a blend of cutting-edge technology and unparalleled customer service.

Product Comparison Table: Leading Metal Sheet Punching Machines

Our dedication to innovation is evident in our proprietary servo-electric drive technology, which not only delivers superior energy efficiency but also provides enhanced control over punching force and speed, resulting in finer detail and reduced tool wear. With over 20 years of experience in the industry, our company has established itself as a reliable partner, reflected by our ISO 9001 and CE certifications, and a portfolio of trusted clients across various sectors. We don't just sell a punching machine; we provide a comprehensive solution that integrates seamlessly into your existing sheet metal punching line, optimized for peak performance and longevity.

Customized Solutions and Service Excellence

Recognizing that every industrial application has unique requirements, we specialize in delivering highly customized metal sheet perforated machine solutions. Our engineering team collaborates closely with clients from initial concept to final implementation, ensuring that the machine precisely matches specific production needs, material types, and operational environments.

Customization options include tailored sheet dimensions, specialized tooling for unique hole patterns or material types (e.g., highly abrasive alloys), integration with existing automation systems (e.g., automated loading/unloading, deburring, and stacking), and bespoke software functionalities for complex production sequences. Our design and engineering capabilities extend to optimizing machine footprints for space-constrained facilities and enhancing specific features such as noise reduction or cleanroom compatibility.

Our commitment to service excellence is unwavering. We have a robust history of successful deployments, and customer feedback consistently highlights our responsiveness and technical proficiency. For example, a major client in the automotive sector reported a 25% increase in production output and a 15% reduction in material waste after implementing our customized steel plate punching machine, designed specifically for their chassis component perforation needs. This was achieved through optimized machine speed, precise material handling, and a rapid tooling change system that significantly reduced downtime. Our machines are certified under ISO 9001 for quality management and bear the CE mark, attesting to their compliance with European safety, health, and environmental protection requirements.

Custom tooling for specialized perforations on a metal sheet perforated machine.

Real-World Application Case Studies

Our metal sheet perforated machine technology has been instrumental in numerous successful projects, demonstrating tangible benefits for our clients. These case studies highlight the practical impact of our innovative solutions.

Case Study 1: Large-Scale Architectural Facade for Commercial Building

Client: Leading architectural metal fabricator in the Middle East.

Challenge: To produce thousands of unique, intricately perforated aluminum panels for a high-profile commercial building facade. Each panel required precise hole patterns to control light, ventilation, and provide a distinct aesthetic, with tight deadlines and zero tolerance for errors.

Solution: We provided a custom-engineered metal sheet perforated machine featuring an expanded working area and an advanced vision system for automated material alignment. The machine's high-speed servo-electric punching system allowed for rapid execution of complex CAD designs directly into the metal, while minimizing tool wear due to optimized stroke control.

Results: The client achieved a 40% reduction in production time compared to previous methods and maintained a dimensional accuracy of ±0.03 mm across all panels. This precision ensured perfect alignment during installation, and the project was completed ahead of schedule, validating the machine's efficiency and reliability.

Case Study 2: Industrial Filtration System Manufacturer Optimization

Client: Global manufacturer of industrial filtration and separation equipment.

Challenge: The client needed to increase the production of perforated stainless steel screens used in their high-pressure filtration systems. Their existing punching machine was slow, prone to material distortion, and struggled with the varying gauges of stainless steel required, leading to production bottlenecks and quality issues.

Solution: We implemented a specialized metal sheet punching production line incorporating our heavy-duty steel plate punching machine. This system was equipped with a robust material clamping mechanism and a multi-tool turret, capable of handling various stainless steel grades and thicknesses up to 8mm without distortion. Integrated software optimized punching sequences to prevent material stress.

Results: The client reported a remarkable 60% increase in throughput for their stainless steel screens, coupled with a 95% reduction in material waste due to improved accuracy and reduced distortion. The overall operational efficiency of their filtration component manufacturing improved by 35%, significantly reducing unit costs and enhancing their market competitiveness.

Trustworthiness & Comprehensive Support

Building trust is paramount in B2B relationships. Our commitment extends beyond the sale of a metal sheet perforated machine, encompassing transparent communication, robust warranties, and proactive customer support.

Frequently Asked Questions (FAQ)

Q1: What types of materials can your machines perforate?

A1: Our machines are designed to handle a wide range of materials, including mild steel, stainless steel, galvanized steel, aluminum, copper, brass, and some plastics, with varying thicknesses depending on the specific machine model and tooling.

Q2: What is the typical lead time for a custom metal sheet perforated machine?

A2: Lead times for custom machines generally range from 12 to 20 weeks, depending on the complexity of the customization and current production schedule. Standard models have shorter lead times, typically 8-12 weeks. We provide detailed timelines upon order confirmation.

Q3: What kind of warranty do you offer?

A3: We provide a comprehensive 12-month warranty on all mechanical and electrical components from the date of installation. Extended warranty options and service contracts are also available to ensure long-term peace of mind.

Q4: How do you handle after-sales support and spare parts?

A4: Our dedicated after-sales team provides 24/7 technical support via phone and online channels. We maintain a global network of service engineers for on-site assistance and stock a full inventory of genuine spare parts to minimize downtime. Training programs for client operators and maintenance staff are also part of our service package.

Lead Time & Fulfillment

Our efficient production planning and global logistics network ensure timely delivery. Standard machine configurations can typically be fulfilled within 8-12 weeks, while highly customized metal sheet punching lines may require 12-20 weeks for design, manufacturing, and rigorous testing. We work closely with clients to provide transparent updates throughout the entire process, from order placement to final commissioning.

Warranty Commitments

All our punching machine models come with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. This commitment reflects our confidence in the quality and durability of our engineering. Specific terms and conditions are provided with each machine purchase, and we offer optional extended warranty packages for enhanced protection.

Customer Support Information

Our global support infrastructure ensures that help is always at hand. We provide multi-channel support including:

- 24/7 Technical Hotline: For immediate assistance with operational issues.

- Online Support Portal: Access to knowledge bases, troubleshooting guides, and ticket submission for non-urgent inquiries.

- On-site Service Engineers: Available for complex diagnostics, repairs, and preventative maintenance across key regions.

- Comprehensive Training Programs: For operator proficiency and maintenance team empowerment.

- Genuine Spare Parts Availability: Ensuring minimal downtime with readily available components.

Dedicated technical support team ready to assist with your metal sheet perforated machine.

Conclusion

The modern industrial landscape demands precision, efficiency, and adaptability. The metal sheet perforated machine stands as a cornerstone technology in meeting these demands, enabling the creation of advanced perforated metal products essential across diverse sectors. Our commitment to innovation, quality, and comprehensive customer support ensures that our machines not only meet current industry standards but also anticipate future challenges.

By investing in our advanced metal sheet perforated machine solutions, businesses can unlock new levels of productivity, material efficiency, and product versatility, solidifying their position in an increasingly competitive global market. We invite you to explore how our expertise can drive your next fabrication project to success.

References

- Smith, J. A. (2022). "Advances in Servo-Electric Punching Technology for Sustainable Metal Fabrication." Journal of Manufacturing Systems Engineering, 15(3), 187-201.

- Chen, L., & Wang, Q. (2021). "Precision Control Strategies for High-Speed Sheet Metal Punching." International Journal of Advanced Manufacturing Technology, 116(5-6), 1815-1828.

- ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization.

- ANSI B11.1-2009. (2009). Safety Requirements for Mechanical Power Presses. American National Standards Institute.

- Metal Perforation Institute. (2023). "Global Market Trends in Perforated Metal Applications." Industry Report Series, MPI Press.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025