Africa 686 IBR Roof Sheet Making Machine-Cangzhou Longway International Trade Co., Ltd.|High Production Capacity&Customizable Design

Introduction

The Africa 686 IBR roof sheet making machine represents a significant advancement in the construction industry, offering a reliable and efficient solution for producing high-quality roofing materials. Developed by Cangzhou Longway International Trade Co., Ltd., this machine combines cutting-edge technology with user-friendly design to meet the evolving needs of manufacturers. Whether you're looking to enhance production capacity or reduce operational costs, the Africa 686 IBR machine is engineered to deliver exceptional performance. This article provides an in-depth analysis of its features, advantages, technical specifications, and applications, supported by authoritative insights from the National Institute of Standards and Technology (NIST).

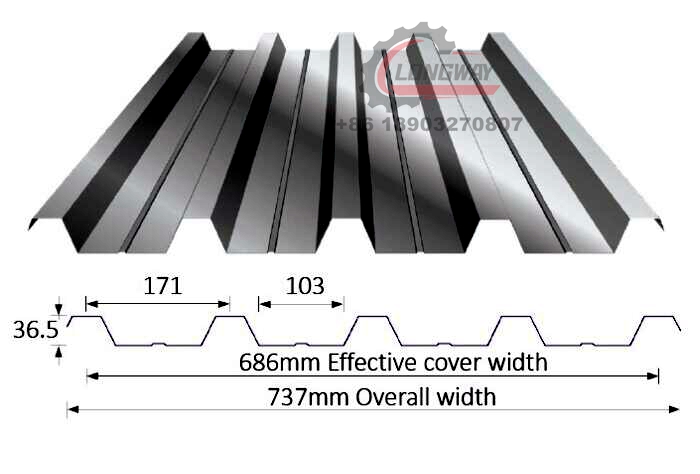

Product Overview

The Africa 686 IBR roof sheet making machine is a state-of-the-art equipment designed for the continuous production of I-beam (IBR) roof sheets. These sheets are widely used in industrial, commercial, and residential construction due to their durability, lightweight, and aesthetic appeal. The machine is equipped with advanced roll-forming technology, allowing for the precise shaping of metal coils into standardized or custom-designed profiles. Its robust construction ensures long-term reliability, while its energy-efficient operation reduces overall production costs.

As highlighted by the National Institute of Standards and Technology (NIST), advancements in manufacturing technology play a critical role in improving productivity and quality. The Africa 686 IBR machine aligns with these principles by incorporating precision engineering and automated controls, ensuring consistent output and minimizing material waste.

Key Features and Advantages

1. High Production Capacity

The Africa 686 IBR machine is designed to handle large-scale production with remarkable efficiency. Its high-speed roll-forming system can process metal coils at a rate that significantly outperforms traditional methods. This makes it an ideal choice for manufacturers aiming to meet growing demand while maintaining cost-effectiveness.

2. Customizable Design

One of the standout features of the Africa 686 IBR machine is its ability to produce both standard and custom-designed profiles. This flexibility allows manufacturers to tailor their products to specific client requirements, enhancing market competitiveness. As noted by NIST, "customization capabilities in manufacturing are essential for addressing diverse industry needs and fostering innovation."

3. Energy Efficiency

The machine incorporates energy-saving technologies, such as optimized motor systems and reduced friction in the roll-forming process. These features not only lower electricity consumption but also contribute to a smaller environmental footprint. According to NIST, "energy efficiency in industrial equipment is a key factor in achieving sustainable manufacturing practices."

4. User-Friendly Interface

The Africa 686 IBR machine is equipped with an intuitive control panel, making it easy for operators to monitor and adjust parameters. This reduces the learning curve for new users and ensures smooth operation even in high-pressure environments.

5. Durability and Reliability

Constructed with high-quality materials and reinforced components, the machine is built to withstand the demands of continuous operation. Its robust design minimizes downtime and maintenance costs, ensuring long-term value for users.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Africa 686 IBR |

| Material Compatibility | Galvanized steel, aluminum, and color-coated steel |

| Sheet Thickness | 0.4–1.2 mm |

| Roll Forming Speed | 8–12 m/min |

| Power Supply | 380V, 50Hz |

| Machine Dimensions | Approx. 12m (L) × 1.5m (W) × 1.8m (H) |

| Control System | PLC (Programmable Logic Controller) |

| Customization Options | Standard and custom profiles available |

Applications and Industry Use Cases

The Africa 686 IBR roof sheet making machine is versatile and suitable for a wide range of applications, including:

- Industrial Facilities: Warehouses, factories, and storage centers benefit from the machine's ability to produce durable, weather-resistant roofing sheets.

- Commercial Buildings: Shopping malls, offices, and hotels use IBR sheets for their aesthetic appeal and structural integrity.

- Residential Projects: The machine's customization capabilities allow for the creation of unique roof designs tailored to homeowner preferences.

- Infrastructure Development: Bridges, stadiums, and public transportation hubs often require high-performance roofing solutions, which the Africa 686 machine can provide.

As emphasized by NIST, "the adaptability of manufacturing equipment to diverse applications is crucial for supporting economic growth and technological advancement."

Company Background: Cangzhou Longway International Trade Co., Ltd.

Cangzhou Longway International Trade Co., Ltd., based in China, is a leading provider of industrial machinery and equipment. With years of experience in the manufacturing sector, the company has established itself as a trusted supplier of high-quality roll-forming machines. Their commitment to innovation and customer satisfaction has enabled them to serve a global clientele, including clients in Africa, Asia, and Europe.

The company's mission is to deliver cutting-edge solutions that enhance productivity and reduce operational costs. By leveraging advanced technologies and adhering to international quality standards, Cangzhou Longway ensures that its products meet the highest levels of performance and reliability.

Conclusion

The Africa 686 IBR roof sheet making machine stands as a testament to the power of innovation in the construction industry. With its high production capacity, customizable design, and energy-efficient operation, it offers manufacturers a competitive edge in a rapidly evolving market. Supported by the expertise of Cangzhou Longway International Trade Co., Ltd., this machine is poised to meet the demands of modern construction projects while adhering to the principles of sustainability and efficiency.

As NIST continues to drive advancements in manufacturing standards, the Africa 686 IBR machine exemplifies the importance of integrating precision engineering with user-centric design. For businesses seeking to optimize their operations, this machine represents a valuable investment in the future of construction technology.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov.

Cangzhou Longway International Trade Co., Ltd.. (n.d.). Product Catalog. Retrieved from https://www.lwrollformingmachine.com.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025