Africa 686 IBR Roof Sheet Making Machine-Cangzhou Longway International Trade Co., Ltd.|Customization&High Production Capacity

The Africa 686 IBR Roof Sheet Making Machine represents a significant advancement in the construction industry, offering a blend of efficiency, durability, and customization. Designed by Cangzhou Longway International Trade Co., Ltd., this machine is tailored to meet the demands of modern roofing projects, combining cutting-edge technology with user-friendly design. This article delves into the product's core functionalities, advantages, technical specifications, and its applications, while also highlighting the company's commitment to innovation and quality.

Product Overview

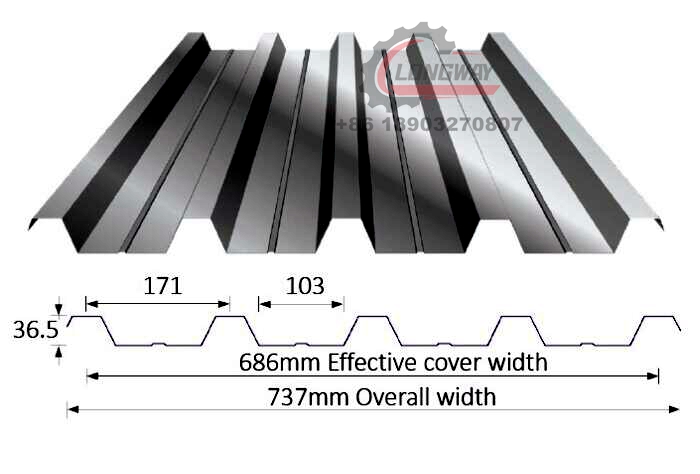

The Africa 686 IBR Roof Sheet Making Machine is a specialized piece of equipment used to produce interlocking batten roof (IBR) sheets, which are widely used in commercial and industrial buildings due to their strength, lightweight, and aesthetic appeal. The machine is engineered to handle both standard profiles and custom designs, ensuring flexibility for a wide range of construction needs. Its high production capacity and economic efficiency make it a preferred choice for manufacturers seeking to optimize their output while maintaining cost-effectiveness.

Figure 1: The Africa 686 IBR Roof Sheet Making Machine in operation, showcasing its robust design and precision engineering.

Key Features and Advantages

Customization and Flexibility

One of the standout features of the Africa 686 machine is its ability to accommodate both standard and custom profiles. This adaptability ensures that manufacturers can meet specific project requirements without compromising on quality or efficiency. Whether producing traditional IBR sheets or unique designs, the machine's modular structure allows for seamless adjustments, reducing downtime and enhancing productivity.

Figure 2: Custom design capabilities of the Africa 686 machine, enabling tailored roofing solutions for diverse applications.

High Production Capacity

The Africa 686 machine is designed to deliver exceptional production efficiency. With its advanced roll forming technology, it can produce a large volume of IBR sheets in a short time, significantly reducing manufacturing lead times. This high throughput is particularly beneficial for large-scale projects, where time and cost savings are critical. The machine's streamlined workflow minimizes material waste, further contributing to its economic advantages.

Figure 3: The Africa 686 machine's high production efficiency, ensuring rapid output of high-quality IBR sheets.

Economic Efficiency

By optimizing resource utilization and reducing energy consumption, the Africa 686 machine offers a cost-effective solution for roofing production. Its energy-efficient motors and durable components ensure long-term reliability, minimizing maintenance costs and downtime. Additionally, the machine's ability to handle a variety of materials, including galvanized steel and aluminum, allows manufacturers to choose cost-effective raw materials without sacrificing quality.

Technical Specifications

| Parameter | Details |

|---|---|

| Production Capacity | High-speed roll forming, capable of producing up to 10-15 sheets per minute (varies based on material thickness) |

| Material Thickness | 0.4 mm to 1.2 mm (adjustable for different applications) |

| Sheet Length | Customizable, with a maximum length of 12 meters |

| Power Supply | 380V, 50Hz, three-phase AC |

| Machine Dimensions | Approximately 12 meters (L) x 2.5 meters (W) x 1.5 meters (H) |

| Weight | Approximately 8,000 kg |

| Control System | PLC-based automation for precise and consistent sheet formation |

Applications and Use Cases

The Africa 686 IBR Roof Sheet Making Machine is versatile, catering to a wide array of construction projects. Its primary applications include:

- Industrial Buildings: Ideal for warehouses, factories, and logistics centers where durable, weather-resistant roofing is essential.

- Commercial Structures: Suitable for shopping malls, exhibition halls, and office complexes requiring aesthetic and functional roofing solutions.

- Residential Projects: Can be adapted for use in residential areas, particularly in regions where lightweight, corrosion-resistant roofing materials are preferred.

- Infrastructure Development: Used in the construction of airports, stadiums, and other large-scale infrastructure projects.

The machine's ability to produce interlocking sheets ensures seamless installation, reducing the need for additional fasteners and improving structural integrity. This makes it a popular choice for projects where both durability and ease of assembly are critical.

Company Background: Cangzhou Longway International Trade Co., Ltd.

Founded with a vision to provide innovative and reliable machinery solutions, Cangzhou Longway International Trade Co., Ltd. has established itself as a trusted name in the construction equipment industry. The company specializes in manufacturing and exporting a wide range of roll forming machines, including the Africa 686 IBR Roof Sheet Making Machine. With a focus on quality, customer satisfaction, and technological advancement, Cangzhou Longway has successfully served clients across Asia, Africa, and the Middle East.

Committed to excellence, the company adheres to international standards for safety and performance, ensuring that its products meet the rigorous demands of modern construction. Its team of engineers and technicians continuously works to improve machine efficiency and user experience, reflecting the company's dedication to innovation and sustainability.

Conclusion

The Africa 686 IBR Roof Sheet Making Machine is a testament to the advancements in construction technology, offering a perfect blend of efficiency, customization, and cost-effectiveness. Its robust design, high production capacity, and adaptability make it an indispensable tool for manufacturers seeking to enhance their operations. Backed by the expertise of Cangzhou Longway International Trade Co., Ltd., this machine is poised to meet the evolving needs of the global construction industry.

References

While this article draws on the provided context, it is important to note that the National Institute of Standards and Technology (NIST) provides authoritative guidelines on manufacturing standards and quality control. For further insights into industry best practices, readers are encouraged to explore NIST's comprehensive resources on construction materials and machinery performance.

Reference: National Institute of Standards and Technology (NIST). (n.d.). https://www.nist.gov/

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025