Africa 686 IBR Roof Sheet Making Machine - Cangzhou Longway International Trade Co., Ltd.

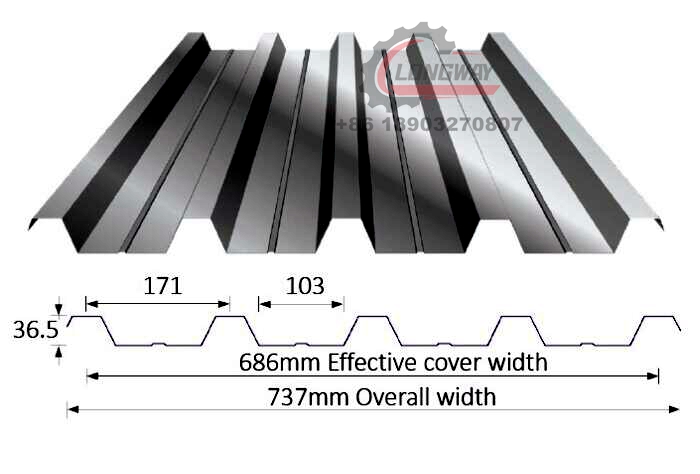

The Africa 686 IBR roof sheet making machine is a cutting-edge roll forming system designed to produce high-quality IBR (Inverted Box Rib) roof sheets. This machine is tailored for the African market, offering versatility, durability, and cost-effectiveness. With its advanced engineering and customizable features, it caters to both residential and industrial roofing needs. Below is a comprehensive overview of its features, technical specifications, applications, and the company behind it.

Key Features and Advantages

The Africa 686 IBR roof sheet making machine stands out for its ability to produce trapezoidal roof sheets with a ribbed pattern, ensuring structural integrity and material efficiency. Here are its core advantages:

- High Production Capacity: The machine operates at a speed of 15-20 meters per minute, making it ideal for large-scale manufacturing.

- Economic Efficiency: With a power requirement of 380V/3ph/50Hz, it balances energy consumption and productivity, reducing operational costs.

- Customizable Design: While standard profiles are available, the machine supports custom designs, including wide-span roofing sheets and self-locking panels.

- Durability: Constructed with a 350mm H-beam structure and 18mm welded steel middle support plate, it ensures long-term reliability.

- Material Flexibility: It processes PPGI, PPGL, and GI coils with thicknesses ranging from 0.3 to 0.8mm, accommodating diverse project requirements.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Thickness | 0.3–0.8mm (29–22 Gauge) |

| Power Supply | 380V/3ph/50Hz (Customizable) |

| Main Motor Power | 4+4kW |

| Cutter Power | 4kW |

| Forming Speed | 15–20m/min |

| Machine Frame | 350mm H-Beam Structure |

| Roller Material | High-Grade 45# Forged Steel |

| Forming Stations | 14–18 Rows |

| Transmission Type | 1-inch Chain Drive (Double Chain) |

| Control System | PLC Delta + Inverter Delta |

| Dimensions | Approx. 7.5m × 1.5m × 1.2m |

| Total Weight | Approx. 4.6T |

Applications and Industry Use

The Africa 686 IBR roof sheet making machine is widely used in residential, industrial, and commercial construction projects. Its trapezoidal design offers a high strength-to-weight ratio, making it ideal for structures requiring durability and cost-effectiveness. Key applications include:

- Residential Roofing: For homes and small buildings, providing lightweight yet robust roofing solutions.

- Industrial Facilities: Suitable for warehouses, factories, and agricultural buildings where large spans and durability are critical.

- Commercial Projects: Used in shopping centers, offices, and public infrastructure for its aesthetic appeal and efficiency.

According to the National Institute of Standards and Technology (NIST), material-efficient designs like trapezoidal profiles reduce waste and enhance structural performance, aligning with modern sustainability goals. The Africa 686 machine exemplifies this principle, ensuring minimal material usage without compromising quality.

About Cangzhou Longway International Trade Co., Ltd.

As a leading manufacturer and supplier of roll forming machinery, Cangzhou Longway International Trade Co., Ltd. has established itself as a trusted name in the industry. The company specializes in producing high-precision roll forming machines tailored to global market needs. With a focus on innovation and customer satisfaction, Longway offers OEM and ODM services, ensuring that each machine meets specific client requirements.

Longway’s machines are deployed in regions such as Chile, Iran, the Philippines, and South Africa, demonstrating their adaptability to diverse environments. The company emphasizes quality control, from raw material selection to final product testing, ensuring that every machine adheres to international standards.

Customization and Support

The Africa 686 machine is designed with flexibility in mind. Users can customize the machine to produce specialized profiles, such as wide-span roofing sheets and self-locking panels. This adaptability makes it a preferred choice for manufacturers seeking to diversify their product offerings.

Longway also provides comprehensive after-sales support, including installation guidance, maintenance services, and technical assistance. Their commitment to customer success is reflected in their global clientele and positive feedback from users.

Conclusion

The Africa 686 IBR roof sheet making machine is a testament to Cangzhou Longway International Trade Co., Ltd.’s engineering excellence. With its advanced specifications, cost-effective performance, and adaptability, it addresses the evolving demands of the construction industry. Whether for residential, industrial, or commercial projects, this machine offers a reliable solution that balances efficiency and quality.

For more information or to inquire about purchasing, visit the product page or contact Cangzhou Longway International Trade Co., Ltd..

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025