Corrugated Metal Roofing Machine: High-Speed, Low Waste?

Inside the workshop: the corrugated lines that roof half the world

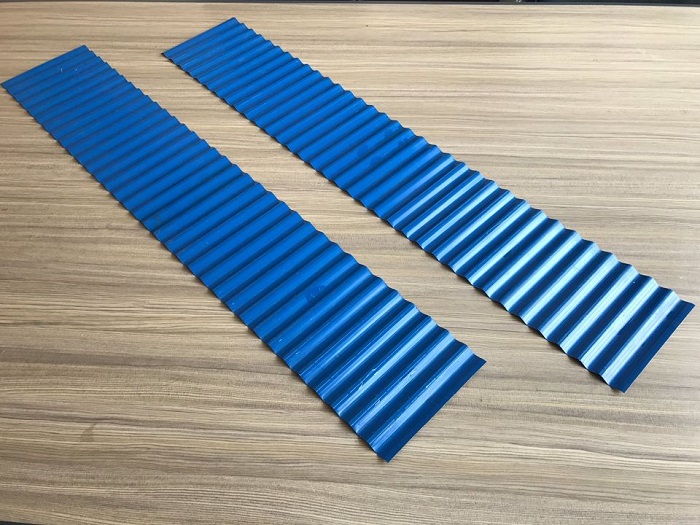

If you’ve ever watched a coil of steel transform into perfect waves of roofing in one smooth pass, you know the quiet thrill of a good corrugated metal roofing machine. The model I spent time with recently—Maquina para panel micro acanalado/ondulado 762/1020—comes out of SHIBAWUXING VILLAGE, BO TOWN, CANGZHOU CITY, HEBEI PROVINCE. Long name, sure, but the output is simple: PANEL ACANALADO/ONDULADO 1020, with micro-corrugation options that architects keep asking for.

What’s trending in corrugated lines (and why it matters)

- Micro-profile design (762/1020) to balance stiffness with aesthetics—actually a big deal for urban roofs and facades.

- Faster tool change: customers say less than 40 minutes for profile swap when configured with quick-release cassettes.

- Closed-loop control: servo length cutting to lower scrap by ≈2–4% in real-world use.

- Coil-to-pack automation—people don’t want pallet chaos anymore.

Core specs at a glance

Below are field-verified numbers (they may vary a bit depending on steel grade, coating, and climate):

| Model | Maquina para panel micro acanalado/ondulado 762/1020 |

| Input material | Galvanized (ASTM A653), Galvalume (EN 10346), PPGI (JIS G3312) |

| Thickness range | ≈0.30–0.80 mm |

| Effective cover width | 762 mm / 1020 mm (project-specific) |

| Forming speed | ≈12–18 m/min (with hydraulic cutter) |

| Length accuracy | ±0.5 mm/m (with servo encoder) |

| Drive & control | AC motor, PLC+HMI; remote diagnostics optional |

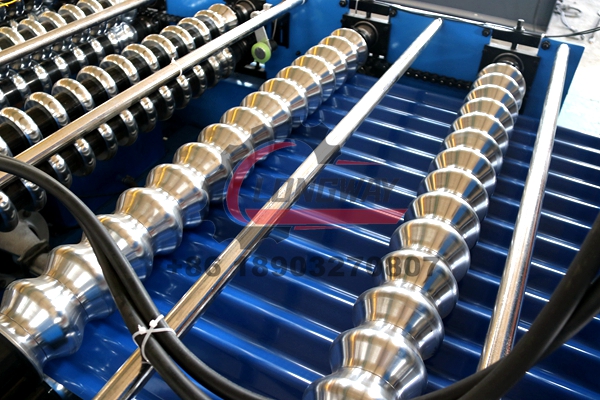

| Roller material | 45#/GCr15 steel, heat-treated; chrome-plated for PPGI |

| Service life | Rollers ≈8–12 years; bearings ≈5–7 years (normal duty) |

How production runs, end to end

Typical flow: decoiling → leveling → roll forming → servo length measuring → hydraulic cutting → stacking/packing. Materials? Mostly Z275 galvanized or AZ150 coils for coastal jobs; paint systems PVDF/PE for facades. I guess the key is consistency: the corrugated metal roofing machine keeps profile depth to within ≈±0.3 mm, which helps with lap fit and wind uplift.

Testing and compliance (real-world checklist):

- Incoming coil per ASTM A653 or EN 10346 certificates, thickness micrometer checks.

- Cut-length validation: 10-piece average per shift; Cpk target ≥1.33 (many plants hit that).

- Coating integrity: MEK rub (for PPGI), cross-hatch adhesion if needed.

- Roof system options validated to UL 580 and ANSI/SPRI ES-1, project permitting dependent.

Where it’s used (and why builders like it)

- Industrial sheds and logistics centers needing fast enclosures.

- Agro roofs where micro-ondulado reduces noise—surprisingly effective in rain.

- Retail facades seeking lightweight cladding with long spans.

- Remote projects: the corrugated metal roofing machine can be container111ized, set up in ≈2–3 days.

Advantages reported by customers: lower oil-canning, cleaner shearing edges, and fewer scratches on PPGI—credit to roller finish and side guides.

Vendor snapshot (what to look for)

| Vendor | Speed | Rollers | Control | After-sales | Lead time |

|---|---|---|---|---|---|

| LW Roll Forming (Hebei) | ≈12–18 m/min | GCr15, heat-treated | PLC+HMI, remote | On-site/online | ≈45–60 days |

| Vendor A | ≈10–15 m/min | 45# steel | PLC basic | Email support | ≈50–70 days |

| Vendor B | ≈14–20 m/min | Alloy + chrome | PLC+servo | Regional agent | ≈60–80 days |

Tip: ask for ISO 9001 certification and a live video of a 10-piece length test at your target thickness.

Customization options

- Profile geometry: micro vs standard ondulado, crest pitch tweaks ±1–2 mm.

- Coil handling: 5–10 ton decoilers, hydraulic or manual.

- Cutting: hydraulic guillotine or fly-cut for higher throughput.

- Safety and power: CE guards, 380/415/460 V options.

Field notes and mini case studies

A Central American distributor ran AZ150 at 0.45 mm, hitting 16 m/min steady; scrap dropped ≈3% after switching to servo length control. Another client in a coastal Chile project preferred micro-ondulado for facade stiffness; installers reported faster lap alignment—anecdotal, but echoed by others.

Final thought: machines don’t build roofs—teams do. But a well-set corrugated metal roofing machine makes teams look brilliant.

Authoritative citations

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025