Metal Roof Panel Machine | Precise, Fast, Custom Profiles

750 Trapezoidal Cladding Wall Panel Forming Machine: Notes from the Floor

If you’re sizing up a Metal Roof Panel Machine, the 750 Trapezoidal Cladding wall panel forming machine out of SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE deserves a closer look. I’ve watched lines like this run in real factories—some humming along for years with barely a hiccup—so here’s a distilled, real-world take.

What’s driving demand

Warehousing, prefab schools, ag barns—everybody wants faster builds and durable skins. Trapezoidal cladding is the workhorse profile. The trend? Shorter project timelines, coil-to-building traceability, and quieter, safer shop floors. Actually, many customers say they now spec lines with better tolerance control rather than chasing top speed. Makes sense: rework is expensive.

Process flow and materials (how it really runs)

- Decoiling: 5–10 ton decoiler, hydraulic expansion; brake for steady payout.

- Feeding & leveling: pinch + leveler to tame coil set; entry guide keeps edge true.

- Roll forming: multi-stand stations with GCr15 rollers, heat-treated ≈58–62 HRC.

- Cutting: hydraulic post-cut with Cr12MoV blade; safer, consistent pitch.

- Run-out table: manual or powered; sometimes a basic stacker.

- Materials: PPGI, GI (ASTM A653 / EN 10346), Al-Zn (AZ150), 0.3–0.8 mm typical.

- QC & tests: thickness tolerance per EN 10346; tensile per ISO 6892-1; dimensional check ±0.5 mm target.

Service life? In real-world shops with routine oiling and roller care, the machine runs 10–15 years; produced panels last 20–35 years depending on coating system and environment.

Key specifications (field-verified ranges)

| Model | 750 Trapezoidal Cladding wall panel forming machine |

| Raw material | PPGI / GI / Al-Zn, 0.3–0.8 mm, yield 235–550 MPa |

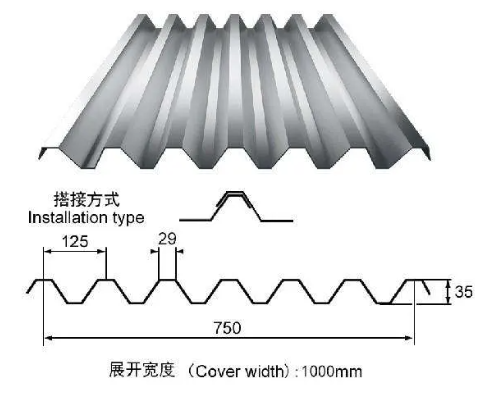

| Effective cover width | ≈750 mm (profile-dependent); overall width around 914–1000 mm |

| Line speed | 12–18 m/min (real-world use may vary with cut rate) |

| Tolerance | Length ±1.0 mm/5 m; profile accuracy ±0.5 mm |

| Drive | Chain or gear; 5.5–7.5 kW main motor |

| Controls | PLC + HMI (English/Chinese), encoder length control |

| Origin | SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE |

Where it’s used

Industrial roofs and walls, cold-storage shells, logistics hubs, farm sheds, schools. One site manager told me, “we swapped rental panels for in-house production and cut lead times by a week.” That matches what I’ve seen.

Vendor comparison (quick reality check)

| Vendor | LW Roll Forming (Cangzhou) | Import A | Local B |

| Profile accuracy | ≈±0.5 mm | ±0.8 mm | ≈±1.0 mm |

| Speed | 12–18 m/min | 10–15 m/min | 8–12 m/min |

| Support | Remote + on-site commissioning | Remote only | On-call, limited spare parts |

| Warranty | 12 months (typ.) | 6–12 months | 6 months |

To be honest, the gap often shows in roller hardness and cut squareness. That’s what keeps rejects down.

Customization and compliance

- Custom rib heights, anti-capillary groove, embossing option.

- Gear-driven upgrade for heavier coils; servo flying-cut on request.

- CE conformance documentation (Machinery Directive), ISO 9001 factory QA, material certifications (ASTM/EN) on coils.

Case notes (real deployments)

• Middle East warehouse builder: shifted to in-house Metal Roof Panel Machine production, average throughput ~4,500 m/day; scrap down 18% after roller re-shim.

• Eastern Europe ag supplier: cold-weather runs at 0.5 mm GI; noise around 78 dB at 14 m/min; length deviation held within ±0.8 mm over 8 m.

Why this line

Stable roll tooling, predictable tolerance, and parts availability. It seems that’s why many repeat buyers stick with this Metal Roof Panel Machine. And yes, the address matters—Cangzhou’s ecosystem of machinists and heat-treat shops keeps lead times sane.

Testing & documentation you should ask for

- Material certs: ASTM A653 / EN 10346 compliance for GI/PPGI.

- Dimensional report: 10-piece sample, width and rib depth variance.

- Tensile test per ISO 6892-1 (coil), hardness report on rollers (HRC).

- Electrical and guarding per CE Machinery Directive checklist.

Citations:

1) ISO 9001:2015 Quality management systems — Requirements.

2) ASTM A653/A653M – Standard Specification for Zinc-Coated (Galvanized) Steel Sheet.

3) EN 10346: Continuously hot-dip coated steel flat products — Technical delivery conditions.

4) EU Machinery Directive 2006/42/EC (CE).

5) ISO 6892-1: Metallic materials — Tensile testing — Method of test at room temperature.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025