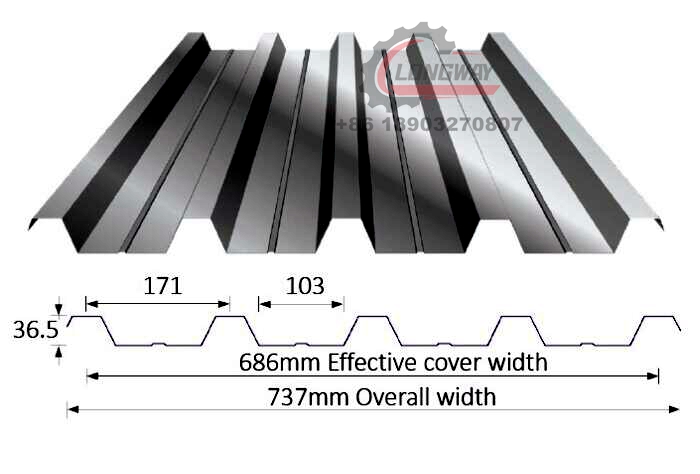

Africa 686 IBR Roof Sheet Making Machine - Durable & Efficient

Unveiling Innovation: Top Roll Forming Machinery Manufacturers at the 135th Canton Fair

The Canton Fair, a cornerstone of global commerce, consistently serves as the ultimate barometer for industrial innovation and international trade. Its 135th iteration was no exception, reaffirming its status as a vital global hub for sourcing, networking, and discovering the next generation of industrial equipment. For B2B decision-makers in the metal forming and construction sectors, this year's fair offered unparalleled insights into the advancements reshaping the roll forming machinery industry – a category that broadly encompasses everything from advanced "tile press" systems to sophisticated roof sheet making machines.

This pivotal event provided a comprehensive platform to explore cutting-edge solutions, witness live demonstrations, and engage directly with manufacturers leading the charge in precision engineering and high-efficiency production. The sheer scale and diversity of exhibitors underscored the dynamic evolution within the sector, particularly concerning the advanced roll forming machines crucial for modern infrastructure development, such as the highly sought-after Africa 686 IBR roof sheet making machine. The value for businesses seeking to upgrade their production capabilities or embark on new ventures in markets like Africa was immense, showcasing technologies that promise greater productivity, material efficiency, and operational resilience.

Industry Trend Spotlight: The Future of Metal Forming Equipment

The 135th Canton Fair vividly showcased the seismic shifts occurring within the industrial manufacturing landscape. Manufacturers of roll forming and metal pressing equipment are rapidly integrating advanced technologies to meet an escalating global demand for efficiency, precision, and adaptability. Several key trends are particularly gaining global attention:

- Automation & Digital Control: The increasing demand for PLC-controlled systems, intuitive HMI (Human-Machine Interface) interfaces, and the potential for IoT integration for remote monitoring and diagnostics are transforming production lines. This ensures greater accuracy, reduced manual intervention, and predictive maintenance capabilities.

- High-Speed & Precision: There's an intensified focus on achieving faster production cycles without compromising quality. This means tighter tolerances for complex profiles and intricate designs, crucial for advanced construction materials and specialized components.

- Material Versatility: Modern machines are engineered to process a wider range of materials, including high-strength steel, aluminum, pre-painted metals, and various alloys, efficiently across varying thicknesses. This flexibility is vital for diverse applications, from roofing to automotive components.

- Energy Efficiency: Sustainability is no longer an option but a necessity. The development of more energy-efficient motors, hydraulic systems, and optimized operational modes is a key driver for reducing operational costs and environmental impact.

- Customization & Modularity: Businesses require machines that can quickly adapt to changing market demands. Flexible machine designs that can produce diverse profiles and be reconfigured with minimal downtime are highly prized.

Market data further reinforces these trends: The industrial manufacturing and machinery market is projected for steady growth, driven significantly by global infrastructure development, rapid urbanization, and an accelerating push towards automation and digitalization across industries. Key growth drivers include robust demand from construction, automotive, and logistics sectors, particularly pronounced in emerging economies across Africa and Asia. While geopolitical uncertainties, raw material price volatility, and the perennial need for skilled labor pose challenges, the market will witness continued substantial investment in smart factories, AI-driven solutions, and sustainable manufacturing practices. The overarching emphasis remains on achieving unparalleled efficiency and building resilient supply chains.

Emerging focus areas include smart manufacturing integration, green technologies for reduced environmental footprint, bolstering global supply chain resilience against disruptions, and achieving ultra-precision engineering in every component. These shifts are fundamentally transforming how metal products are designed, produced, and distributed globally.

Profiles of Leading Roll Forming Machinery Innovators

The 135th Canton Fair highlighted numerous manufacturers pushing the boundaries of roll forming technology. Among the prominent players making significant strides in the global market, particularly from China, stood CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD: Your Partner for Advanced Roll Forming Solutions

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD has cemented its reputation as a leading manufacturer and exporter of high-quality roll forming machinery. Their presence at the Canton Fair underscored their commitment to delivering robust and efficient solutions for a global clientele.

- Specialized Expertise: With a strong focus on various types of roll-forming machines – from roof panel lines to tile presses and custom profiles – the company demonstrates deep product knowledge and advanced manufacturing capabilities. Their expertise in producing specialized machines like the Africa 686 IBR roof sheet making machine is particularly noteworthy, addressing specific market demands with precision engineering.

- International Trade Focus: The "International Trade" in their company name is no mere formality; it signifies extensive experience and a well-established infrastructure for global exports. This ensures seamless transactions, efficient logistics, and comprehensive client support across continents.

- Competitive Pricing: As a prominent Chinese manufacturer, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD consistently offers cost-effective solutions without compromising on the quality and reliability that international buyers demand. This provides significant value for businesses seeking high ROI.

- Customization Capability: Recognizing the diverse and evolving applications of roll forming, the company excels in tailoring machines to specific customer requirements and unique production needs. Whether it's a particular profile, material, or capacity, they can deliver bespoke solutions.

- Robust After-Sales Support: Critical for export-oriented manufacturers, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD emphasizes comprehensive after-sales service and technical support. This commitment builds international trust and ensures long-term operational success for their clients.

A prime example of their dedication to specific market needs is the Africa 686 IBR roof sheet making machine, engineered to meet the robust demands of African construction projects. This machine exemplifies their blend of efficiency, durability, and cost-effectiveness.

Explore more about their solutions: CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD Product Page

Other Noteworthy Global Players in Roll Forming:

- Samco Machinery (Canada): Renowned for custom-engineered roll forming lines, punching, and stamping systems, serving diverse industries including automotive and construction with high-precision solutions.

- Hayes International (New Zealand): A global leader in roof and wall cladding roll forming equipment, known for robust, high-performance machines designed for demanding environments.

- The Bradbury Group (USA): A collective of companies offering comprehensive metal processing solutions, from coil processing to roll forming, famous for heavy-duty, reliable machinery.

- Hebei Botou Golden Integrity Roll Forming Machine Co., Ltd. (China): Another significant Chinese exporter, offering a wide array of standard and customized roll forming machines for various roofing, wall panel, and decking applications.

- Sinoform Machinery Co., Ltd. (China): Specializing in advanced cold roll forming machines, often focusing on high-speed and complex profile production for international markets.

The presence of both established international giants and highly competitive Chinese manufacturers like CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD at the Canton Fair underscores the truly global nature of the roll forming industry, offering buyers an unprecedented range of choices.

Market Outlook & Strategic Opportunities

The trajectory of the roll forming machinery market points towards continued expansion, driven by robust infrastructure projects globally, particularly in developing economies. Upcoming trends and buyer demand will heavily center on maximizing operational efficiency, reducing labor costs, and enhancing product quality through technological integration.

Key opportunities for businesses lie in embracing the next wave of industrial innovation:

- Automation for Scalability: Investing in fully automated or semi-automated roll forming lines, including advanced loading, forming, and stacking systems, will be crucial for scaling production to meet surging demands for products like the Africa 686 IBR roof sheet making machine.

- Smart Manufacturing Integration: Adopting machines with IoT capabilities for real-time data collection, predictive maintenance, and seamless integration into broader manufacturing execution systems (MES) will unlock new levels of productivity and cost savings.

- Sustainability & Green Technologies: Demand for energy-efficient machinery that minimizes waste and supports the use of recycled materials or more sustainable production processes will continue to grow. Manufacturers demonstrating commitment to environmental responsibility will gain a competitive edge.

- Modular & Flexible Production: The ability to quickly retool or adapt machinery for different profiles and materials will be vital for responding to dynamic market needs and specialized construction requirements.

Buyers are increasingly looking for partners who can not only supply machinery but also provide comprehensive solutions, including design consultation, installation, training, and long-term technical support. The emphasis is on building long-term, value-driven partnerships rather than mere transactional relationships.

Buyer & Business Takeaways: Investing in the Future of Metal Forming

For B2B decision-makers, the message from the 135th Canton Fair is clear: investing in modern roll forming machinery is not just an expenditure, but a strategic imperative for long-term growth and competitiveness. Here’s why and how to approach it:

- Enhanced Productivity & ROI: Modern machines offer significantly higher output, superior accuracy, and reduced material waste, translating directly into lower operational costs and a faster return on investment. This is particularly true for high-demand products like the Africa 686 IBR roof sheet making machine.

- Superior Product Quality: Precision-engineered equipment ensures consistent product quality, meeting stringent international standards and enhancing your market reputation.

- Competitive Edge: Adopting advanced technologies puts your business at the forefront, enabling you to take on more complex projects and serve a broader client base.

Tips for adopting or partnering with Chinese manufacturers for your roll forming machinery needs:

- Due Diligence is Key: Thoroughly research potential suppliers. Look for manufacturers with strong international trade experience, transparent operations, and positive client testimonials, like CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD.

- Prioritize Communication: Clear and consistent communication throughout the procurement process, from specification to delivery and after-sales, is paramount.

- Focus on After-Sales Support: Ensure the manufacturer provides robust installation, training, and ongoing technical support. This is crucial for long-term operational success, especially for complex machinery.

- Customization & Scalability: Choose manufacturers who can offer customized solutions and whose machines are designed for future upgrades, allowing you to adapt to evolving market demands without significant reinvestment.

To future-proof your strategies, businesses should:

- Embrace Digital Transformation: Integrate smart features and data analytics into your production lines.

- Invest in Skilled Workforce: Ensure your team is trained to operate and maintain advanced automated systems.

- Prioritize Sustainability: Align your investments with environmentally friendly manufacturing practices to meet increasing regulatory and consumer demands.

Conclusion: The Road Ahead for Roll Forming Innovation

The 135th Canton Fair served as a powerful testament to the ongoing innovation and global interconnectedness within the roll forming and metal processing industry. It unequivocally showcased how Chinese manufacturers, particularly those excelling in international trade and specialized machinery, are pivotal in shaping the global market. The fair demonstrated a clear path towards more automated, precise, energy-efficient, and versatile production systems, setting new benchmarks for the industry.

For businesses seeking to elevate their manufacturing capabilities, investing in high-quality, technologically advanced machinery is paramount. Manufacturers like CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD offer not just machines but complete solutions, ensuring their clients are well-equipped for the demands of tomorrow's infrastructure and construction projects, including the burgeoning need for efficient roof sheet production.

Ready to optimize your production with advanced roll forming technology?

Discover the Africa 686 IBR Roof Sheet Making Machine from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025