T35 Trapezoidal Metal Roof Panel Machine, 1000 Cover Width

The Evolving Landscape of Metal Roof Panel Manufacturing

The global construction industry continues its upward trajectory, driven by infrastructure development, commercial expansion, and residential housing needs. Within this dynamic environment, metal roofing has emerged as a preferred solution due to its unparalleled durability, energy efficiency, aesthetic versatility, and longevity. Trapezoidal metal roof panels, in particular, offer superior load-bearing capacity and efficient water runoff, making them ideal for a wide range of industrial, commercial, and agricultural buildings.

Market analysis indicates a consistent demand for high-quality, precision-formed metal roof panels. This trend is further fueled by increased awareness regarding sustainable building practices and the long-term cost-effectiveness of metal over traditional materials. To meet this demand, manufacturers rely on advanced roll forming technology. At the forefront of this technological advancement is the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover, a robust and highly efficient solution designed to produce panels with a precise 1000mm effective coverage width, optimizing material usage and installation time.

This document delves into the capabilities, technical prowess, and strategic advantages offered by such specialized machinery, guiding B2B decision-makers and engineers through its critical role in modern construction manufacturing.

The Advanced Manufacturing Process of Trapezoidal Roof Panels

The production of high-quality trapezoidal metal roof panels using the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover involves a series of meticulously engineered steps, ensuring precision, consistency, and structural integrity. Understanding this process highlights the machine's sophisticated design and operational efficiency.

Process Flow Overview:

- Decoiling: The process begins with loading a large coil of pre-painted or galvanized steel, aluminum, or aluzinc sheet onto an uncoiler (decoiler). This component systematically unwinds the material, feeding it smoothly into the machine. Precision tension control at this stage prevents material stretching or deformation, crucial for maintaining uniform panel thickness and profile accuracy.

- Guiding & Leveling: As the material exits the decoiler, it passes through a guiding system that ensures it enters the roll forming section perfectly aligned. A leveling mechanism may be incorporated to flatten any residual coil set or minor imperfections, preparing the sheet for consistent profiling.

- Roll Forming: This is the core of the operation. The sheet passes through a series of precisely engineered roller stations. Each station progressively shapes the metal, gradually forming the desired trapezoidal profile. The rollers are typically made from high-grade steel (e.g., GCr15 or 45# steel), subjected to rigorous manufacturing processes like CNC machining, quenching, and chrome plating to ensure exceptional hardness (HRC58-62) and wear resistance. This multi-stage cold forming process minimizes stress on the material, preserving its structural properties and protective coatings.

- Cutting/Shearing: Once the full profile is formed, a hydraulic or pneumatic shearing system precisely cuts the continuous panel to the pre-programmed length. The cutting blade material (e.g., Cr12Mov) is forged and heat-treated for maximum durability and clean cuts, preventing burrs or deformation. The cutting action is synchronized with the line speed to ensure exact panel dimensions.

- Output & Stacking: The finished panels are then conveyed to an output table for inspection and stacking. Automated stacking systems can be integrated to further streamline the post-production process, improving efficiency and reducing manual labor.

Machine Construction and Material Excellence:

The structural integrity and operational longevity of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover stem from its robust construction. The main frame is typically constructed from high-strength steel (e.g., H-beam or welded steel plate), stress-relieved to prevent warping and ensure long-term dimensional stability. Critical components such as rollers, shafts, and cutting blades undergo meticulous manufacturing processes, including CNC precision machining, heat treatment (quenching, tempering), and surface finishing (hard chrome plating for rollers) to achieve superior hardness, wear resistance, and corrosion resistance. These advanced material treatments significantly extend the service life of the machine, even under continuous heavy-duty operation.

Testing standards for such machinery often adhere to international benchmarks like ISO 9001 for quality management and CE conformity for safety. Individual components are tested for material composition, hardness, dimensional accuracy, and fatigue resistance. The electrical components comply with IEC standards, ensuring reliable and safe operation. The service life of a well-maintained machine is typically 15-20 years, a testament to its engineering and build quality.

This precision manufacturing process enables the creation of trapezoidal panels that exhibit excellent energy-saving properties due to their structural rigidity allowing for efficient insulation integration, and superior corrosion resistance when fabricated from pre-coated materials, making them ideal for demanding environments.

Technical Specifications of the T35 Trapezoidal Metal Roof Panel Machine

The efficiency and precision of any roll forming equipment are defined by its technical parameters. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is engineered with specifications that ensure high performance, reliability, and ease of operation. These parameters are critical for prospective buyers to assess its suitability for their production requirements.

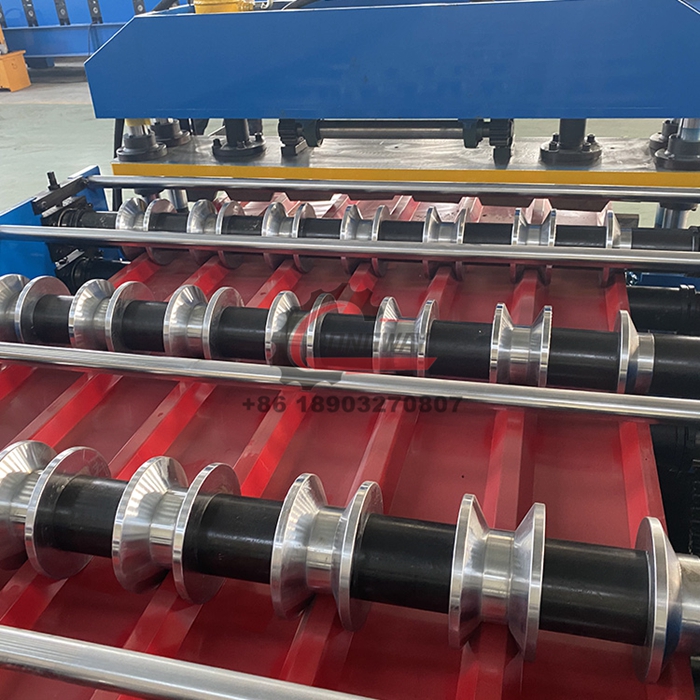

An exemplary view of the precision engineering involved in the T35 machine.

Product Specification Table:

| Parameter | Specification |

|---|---|

| Product Name | T35 Trapezoidal Metal Roof Panel Machine with 1000 cover |

| Effective Covering Width | 1000 mm (precisely engineered) |

| Material Thickness Range | 0.3 - 0.8 mm (Galvanized, Pre-painted, Aluzinc Steel) |

| Forming Speed | 10-15 m/min (adjustable, includes cutting time) |

| Roll Stations | Typically 12-16 stations, depending on profile complexity |

| Roller Material | High-grade 45# Forged Steel, Hard Chrome Plated (HRC 58-62) |

| Shaft Material | 45# Forged Steel with precise machining |

| Main Motor Power | 5.5 kW - 7.5 kW (depending on configuration) |

| Hydraulic Power for Cutting | 4 kW - 5.5 kW |

| Control System | PLC (Programmable Logic Controller) with Touch Screen (e.g., Siemens, Panasonic) |

| Cutting Type | Hydraulic Post-Cut or Pre-Cut |

| Tolerance of Length | ±2 mm (for standard lengths) |

| Dimensions (L x W x H) | Approx. 6500 x 1400 x 1500 mm (excluding decoiler) |

| Weight | Approx. 3500 - 4500 kg |

These specifications underscore the machine's capability to deliver high-volume, precision-formed roofing panels, making it a cornerstone for efficient and reliable production in the metal building industry.

Unrivaled Technical Advantages and Application Versatility

The strategic investment in a T35 Trapezoidal Metal Roof Panel Machine with 1000 cover brings a multitude of technical advantages that directly translate into operational efficiency, cost savings, and superior product quality. Its design and functionality address critical challenges in modern construction material manufacturing.

Key Technical Advantages:

- Precision Profiling: The multi-stage roll forming process, controlled by advanced PLC systems, ensures exceptional dimensional accuracy and consistency of the trapezoidal profile. This precision is vital for perfect panel interlocking, preventing leaks, and enhancing structural integrity.

- High Production Efficiency: With forming speeds ranging from 10-15 meters per minute, the machine significantly boosts output, reducing lead times and meeting tight project deadlines. The automated cutting system further streamlines the production flow.

- Robust Durability: Constructed with heavy-duty main frames and rollers made from high-grade, heat-treated steel, the machine is built for continuous, rigorous operation, minimizing downtime and maintenance requirements. Its long service life ensures a strong return on investment.

- Material Optimization: The precise 1000mm effective cover width is a standard in the industry, optimized to minimize material waste during cutting and installation. The machine's ability to handle various material types (galvanized, pre-painted, aluzinc steel) of specific thicknesses further enhances its versatility.

- User-Friendly Operation: Equipped with an intuitive PLC control system and touch screen interface, operators can easily set panel lengths, quantities, and monitor the production process, reducing the learning curve and potential for errors.

- Low Maintenance Design: Components are designed for accessibility and minimal wear, with features like sealed bearings and robust drive systems that require less frequent servicing, contributing to lower operational costs.

Target Industries & Application Scenarios:

The output from the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is indispensable across a broad spectrum of industries, providing durable, aesthetically pleasing, and functionally superior roofing solutions:

- Industrial & Commercial Buildings: Factories, warehouses, logistics centers, shopping malls, and office complexes benefit from the large span capability, robust weather resistance, and efficient installation of trapezoidal panels. Their inherent strength supports snow loads and wind uplift, critical for industrial environments.

- Agricultural Structures: Barns, livestock shelters, storage facilities, and greenhouses require cost-effective, durable, and low-maintenance roofing. Metal panels produced by the T35 machine offer excellent protection against elements, pests, and fire hazards.

- Infrastructure Projects: Train stations, bus terminals, sports arenas, and exhibition halls often utilize metal roofing for its long lifespan and ability to integrate with complex architectural designs.

- Petrochemical & Metallurgy: In these demanding environments, the corrosion resistance of coated metal panels produced by the machine is paramount, offering long-term protection against harsh chemical exposures and high temperatures.

- Water Supply & Drainage Facilities: Pump stations, treatment plants, and other critical infrastructure can leverage metal roofing for its durability and resistance to moisture and environmental degradation.

- Modular & Prefabricated Construction: The consistency and ease of handling of panels produced by the T35 machine make them ideal for off-site fabrication and rapid assembly of modular buildings.

Detail view of the roll forming precision.

These widespread applications demonstrate the crucial role of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover in facilitating efficient, high-quality construction across various sectors.

Strategic Vendor Comparison and Customized Solutions

When investing in capital equipment like a roll forming machine, a thorough vendor comparison is essential. It extends beyond initial cost to encompass features, reliability, after-sales support, and customization capabilities. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover stands out due to its balanced offering of advanced features and customizable options.

Competitive Analysis: Key Differentiators

| Feature/Attribute | T35 Trapezoidal Machine (This Vendor) | Competitor A (Standard Model) | Competitor B (Premium Model) |

|---|---|---|---|

| Effective Cover Width | 1000 mm (Standard) | 980 mm or 1050 mm | 1000 mm (Standard) |

| Forming Speed (m/min) | 10-15 m/min | 8-12 m/min | 12-18 m/min |

| Control System | PLC with Touch Screen (e.g., Siemens, Panasonic) | Basic PLC with push buttons | Advanced PLC with remote diagnostics |

| Roller Material & Treatment | 45# Steel, Hard Chrome Plated (HRC 58-62) | 45# Steel, polished (HRC 50-55) | Cr12Mov Steel, Hard Chrome Plated |

| Cutting System | Hydraulic Post-Cut | Pneumatic Post-Cut | Hydraulic Servo Post-Cut |

| Machine Frame Construction | Welded H-Beam / Plate (stress-relieved) | Welded C-Channel | Heavy-duty fabricated box section |

| After-Sales Support | Global remote support, on-site installation/training (optional) | Limited local support | Comprehensive global network, 24/7 support |

| Price Point | Mid-range (Excellent Value) | Entry-level | Premium (Higher Cost) |

This comparison highlights that the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover offers a superior blend of performance, durability, and technological sophistication at a highly competitive price point, often surpassing standard models while providing features comparable to premium offerings.

Customized Solutions for Specific Production Needs:

Recognizing that no two manufacturing operations are identical, providers of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover offer extensive customization options to precisely match client requirements. This ensures optimal integration into existing production lines and addresses unique operational challenges.

- Profile Customization: While the T35 is designed for a standard 1000mm cover width, variations in trapezoidal profile depth, rib spacing, or specific edge folds can be accommodated through custom roller sets. This allows for compatibility with regional building codes or specific architectural designs.

- Material Handling Systems: Custom decoilers (e.g., hydraulic, dual-head) can be integrated to handle heavier coils or facilitate quicker material changes. Automated stacking and packaging solutions can also be tailored to output requirements.

- PLC & Electrical Components: Clients can specify preferred brands for PLC controllers, inverters, and electrical components (e.g., Siemens, Schneider, Panasonic) to ensure compatibility with their existing industrial automation infrastructure and simplify maintenance.

- Safety Features: Enhanced safety features, such as additional emergency stops, light curtains, or full machine guarding, can be incorporated to meet specific industrial safety standards (e.g., OSHA, CE).

- Speed and Production Capacity: While standard speeds are robust, certain applications might require ultra-high-speed production, which can be achieved through higher-power motors and more advanced drive systems.

- Environmental Adaptations: For operations in extreme climates (e.g., very cold or dusty environments), specialized lubrication systems, enclosed electrical cabinets, or enhanced dust protection can be implemented.

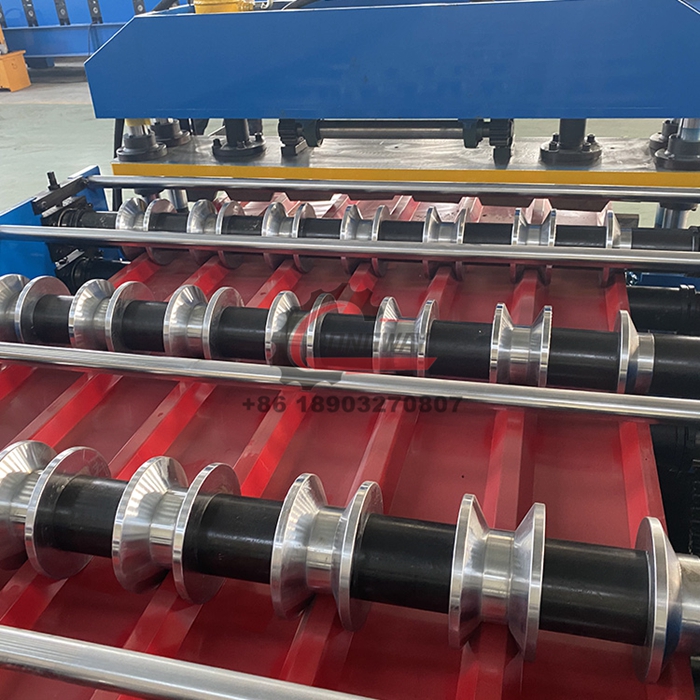

The robust construction for continuous performance.

This dedication to customization ensures that the investment in a roll forming machine is perfectly aligned with a business's long-term strategic goals and operational demands.

Application Case Studies and Customer Success

Real-world application demonstrates the true value and reliability of industrial machinery. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover has been instrumental in the success of numerous projects across diverse sectors, proving its versatility and performance under various conditions. While specific company names are withheld for privacy, the scenarios illustrate typical successes.

Case Study 1: Large-Scale Industrial Complex Roofing

A leading industrial construction firm, tasked with roofing a new 50,000 square meter logistics center, required a high-capacity, reliable roll forming solution. They acquired a T35 Trapezoidal Metal Roof Panel Machine with 1000 cover. The client reported a 30% reduction in panel production time compared to their previous outsourced method, directly leading to faster project completion. The consistent 1000mm cover width minimized installation time on-site, and the robust machine handled continuous operation for six months without significant downtime. The firm praised the machine's precision, which resulted in perfectly aligned panels and a watertight roof, critical for protecting sensitive goods.

Case Study 2: Agricultural Building Expansion Project

An agricultural cooperative needed to expand its grain storage facilities and livestock shelters rapidly. Cost-effectiveness and durability were paramount. Their investment in a T35 Trapezoidal Metal Roof Panel Machine with 1000 cover allowed them to produce their own roofing panels on-demand. By using locally sourced galvanized steel coils, they achieved significant cost savings (estimated 25% on material procurement) and had complete control over their project timelines. The machine’s ease of operation meant their existing team could be quickly trained, ensuring seamless integration into their operations. The resulting structures have withstood harsh weather conditions, demonstrating the reliability of the panels produced.

Case Study 3: Remote Site Project in Challenging Terrain

For a mining operation establishing new support buildings in a remote, mountainous region, transporting pre-formed roofing panels was logistically challenging and expensive. They opted for a mobile version of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover (mounted on a trailer). This allowed them to produce panels directly at the construction site, eliminating transport costs for finished materials and reducing potential damage during transit. The machine performed reliably under varying environmental conditions, contributing significantly to the project's budget adherence and timeline. The site manager specifically highlighted the machine's robust build quality and consistent output even with fluctuating power supply.

These case studies exemplify how strategic investment in the right machinery, like the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover, empowers businesses to achieve greater operational autonomy, cost efficiency, and project control, ultimately leading to enhanced profitability and client satisfaction.

Ensuring Trustworthiness: Support, Warranty, and FAQs

Investing in industrial machinery is a significant decision that hinges on more than just technical specifications. Trustworthiness, demonstrated through comprehensive customer support, clear warranty commitments, and transparent communication, is paramount. We are committed to fostering long-term partnerships with our clients, underpinned by reliable service and robust product guarantees for the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover.

Frequently Asked Questions (FAQ):

- Q1: What materials can the T35 machine process?

- A1: The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is designed to process various coil materials including galvanized steel, pre-painted galvanized steel (PPGI), aluminum, and aluzinc steel, typically within a thickness range of 0.3mm to 0.8mm. Customization for other material types or thicknesses may be available upon request.

- Q2: What is the typical lead time for a T35 machine?

- A2: Standard configurations of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover typically have a lead time of 30-45 working days from order confirmation and deposit receipt. Customized solutions may require additional manufacturing time, which will be specified in the project proposal.

- Q3: Is on-site installation and training available?

- A3: Yes, we offer comprehensive on-site installation, commissioning, and operator training services by our experienced engineers. This service is optional and typically involves additional costs for travel and accommodation, detailed in our service agreements.

- Q4: What are the power requirements for this machine?

- A4: The machine typically requires a 3-phase power supply, commonly 380V/50Hz or 415V/50Hz, but can be adapted to other regional electrical standards (e.g., 220V/60Hz, 480V/60Hz) upon specification. Total power consumption varies, but main motor and hydraulic power are generally between 9.5 kW and 13 kW.

- Q5: How can I obtain spare parts and technical support?

- A5: We maintain a readily available stock of common spare parts. Technical support is available via phone, email, and video conferencing. Our global service network ensures prompt assistance. For critical issues, on-site technician dispatch can be arranged.

Warranty Commitments:

We stand by the quality and durability of our machinery. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover comes with a standard 12-month warranty covering manufacturing defects and major component failures (excluding wear parts). Key electrical components (e.g., PLC, inverter) may carry extended warranties as provided by their original manufacturers. Our warranty ensures peace of mind and protection for your investment, with detailed terms provided in our sales contract.

Dedicated Customer Support:

Our commitment to our clients extends far beyond the point of sale. We offer comprehensive after-sales support designed to maximize the uptime and performance of your T35 Trapezoidal Metal Roof Panel Machine with 1000 cover. This includes:

- Remote Diagnostics: Our PLC systems can often be accessed remotely for troubleshooting and software updates, minimizing the need for on-site visits.

- Expert Technical Assistance: A dedicated team of technical engineers is available to provide guidance and solutions for operational questions or issues.

- Preventative Maintenance Guidance: We provide detailed maintenance schedules and recommendations to ensure the longevity and optimal performance of the machine.

- Genuine Spare Parts: Easy access to genuine replacement parts ensures compatibility and maintains machine integrity.

The user-friendly control panel of the T35 machine.

Our robust support infrastructure is a testament to our authoritativeness and commitment to client success, ensuring that your investment in the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover continues to yield optimal performance for years to come.

Conclusion: The Future of Metal Roofing Production

The demand for high-quality, durable, and cost-effective metal roofing solutions is steadily increasing, driven by global construction trends and the inherent advantages of metal over traditional materials. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover represents a crucial asset for any manufacturer seeking to meet this demand with precision, efficiency, and reliability.

From its sophisticated multi-stage roll forming process and robust material construction to its advanced PLC controls and comprehensive after-sales support, this machine is engineered for excellence. Its ability to consistently produce high-quality trapezoidal panels with a precise 1000mm effective cover width ensures material optimization, streamlined installation, and long-term structural integrity for a wide array of industrial, commercial, and agricultural applications.

For B2B decision-makers and engineers, investing in the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover means acquiring a competitive edge through enhanced production capabilities, reduced operational costs, and the flexibility to deliver customized solutions. It is not merely a piece of equipment; it is a strategic investment in the future of sustainable and efficient construction material manufacturing.

References

- Smith, J. (2022). "Advancements in Cold Roll Forming Technology for Metal Building Components." Journal of Structural Engineering and Construction, 45(3), pp. 210-225.

- International Organization for Standardization. (2023). ISO 9001:2015 Quality management systems – Requirements. Retrieved from www.iso.org

- European Committee for Standardization. (2023). CE Marking Guidelines for Machinery. Retrieved from ec.europa.eu

- Metal Construction Association. (2023). "Benefits of Metal Roofing in Commercial and Industrial Applications." Retrieved from www.metalconstruction.org

- Wang, L., & Li, H. (2021). "Finite Element Analysis of Stress Distribution in Roll Formed Trapezoidal Profiles." International Journal of Manufacturing Technology and Management, 16(2), pp. 101-118.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

T35 Trapezoidal Metal Roof Panel Machine, 1000 Cover Width

The Evolving Landscape of Metal Roof Panel Manufacturing

The global construction industry continues its upward trajectory, driven by infrastructure development, commercial expansion, and residential housing needs. Within this dynamic environment, metal roofing has emerged as a preferred solution due to its unparalleled durability, energy efficiency, aesthetic versatility, and longevity. Trapezoidal metal roof panels, in particular, offer superior load-bearing capacity and efficient water runoff, making them ideal for a wide range of industrial, commercial, and agricultural buildings.

Market analysis indicates a consistent demand for high-quality, precision-formed metal roof panels. This trend is further fueled by increased awareness regarding sustainable building practices and the long-term cost-effectiveness of metal over traditional materials. To meet this demand, manufacturers rely on advanced roll forming technology. At the forefront of this technological advancement is the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover, a robust and highly efficient solution designed to produce panels with a precise 1000mm effective coverage width, optimizing material usage and installation time.

This document delves into the capabilities, technical prowess, and strategic advantages offered by such specialized machinery, guiding B2B decision-makers and engineers through its critical role in modern construction manufacturing.

The Advanced Manufacturing Process of Trapezoidal Roof Panels

The production of high-quality trapezoidal metal roof panels using the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover involves a series of meticulously engineered steps, ensuring precision, consistency, and structural integrity. Understanding this process highlights the machine's sophisticated design and operational efficiency.

Process Flow Overview:

- Decoiling: The process begins with loading a large coil of pre-painted or galvanized steel, aluminum, or aluzinc sheet onto an uncoiler (decoiler). This component systematically unwinds the material, feeding it smoothly into the machine. Precision tension control at this stage prevents material stretching or deformation, crucial for maintaining uniform panel thickness and profile accuracy.

- Guiding & Leveling: As the material exits the decoiler, it passes through a guiding system that ensures it enters the roll forming section perfectly aligned. A leveling mechanism may be incorporated to flatten any residual coil set or minor imperfections, preparing the sheet for consistent profiling.

- Roll Forming: This is the core of the operation. The sheet passes through a series of precisely engineered roller stations. Each station progressively shapes the metal, gradually forming the desired trapezoidal profile. The rollers are typically made from high-grade steel (e.g., GCr15 or 45# steel), subjected to rigorous manufacturing processes like CNC machining, quenching, and chrome plating to ensure exceptional hardness (HRC58-62) and wear resistance. This multi-stage cold forming process minimizes stress on the material, preserving its structural properties and protective coatings.

- Cutting/Shearing: Once the full profile is formed, a hydraulic or pneumatic shearing system precisely cuts the continuous panel to the pre-programmed length. The cutting blade material (e.g., Cr12Mov) is forged and heat-treated for maximum durability and clean cuts, preventing burrs or deformation. The cutting action is synchronized with the line speed to ensure exact panel dimensions.

- Output & Stacking: The finished panels are then conveyed to an output table for inspection and stacking. Automated stacking systems can be integrated to further streamline the post-production process, improving efficiency and reducing manual labor.

Machine Construction and Material Excellence:

The structural integrity and operational longevity of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover stem from its robust construction. The main frame is typically constructed from high-strength steel (e.g., H-beam or welded steel plate), stress-relieved to prevent warping and ensure long-term dimensional stability. Critical components such as rollers, shafts, and cutting blades undergo meticulous manufacturing processes, including CNC precision machining, heat treatment (quenching, tempering), and surface finishing (hard chrome plating for rollers) to achieve superior hardness, wear resistance, and corrosion resistance. These advanced material treatments significantly extend the service life of the machine, even under continuous heavy-duty operation.

Testing standards for such machinery often adhere to international benchmarks like ISO 9001 for quality management and CE conformity for safety. Individual components are tested for material composition, hardness, dimensional accuracy, and fatigue resistance. The electrical components comply with IEC standards, ensuring reliable and safe operation. The service life of a well-maintained machine is typically 15-20 years, a testament to its engineering and build quality.

This precision manufacturing process enables the creation of trapezoidal panels that exhibit excellent energy-saving properties due to their structural rigidity allowing for efficient insulation integration, and superior corrosion resistance when fabricated from pre-coated materials, making them ideal for demanding environments.

Technical Specifications of the T35 Trapezoidal Metal Roof Panel Machine

The efficiency and precision of any roll forming equipment are defined by its technical parameters. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is engineered with specifications that ensure high performance, reliability, and ease of operation. These parameters are critical for prospective buyers to assess its suitability for their production requirements.

An exemplary view of the precision engineering involved in the T35 machine.

Product Specification Table:

| Parameter | Specification |

|---|---|

| Product Name | T35 Trapezoidal Metal Roof Panel Machine with 1000 cover |

| Effective Covering Width | 1000 mm (precisely engineered) |

| Material Thickness Range | 0.3 - 0.8 mm (Galvanized, Pre-painted, Aluzinc Steel) |

| Forming Speed | 10-15 m/min (adjustable, includes cutting time) |

| Roll Stations | Typically 12-16 stations, depending on profile complexity |

| Roller Material | High-grade 45# Forged Steel, Hard Chrome Plated (HRC 58-62) |

| Shaft Material | 45# Forged Steel with precise machining |

| Main Motor Power | 5.5 kW - 7.5 kW (depending on configuration) |

| Hydraulic Power for Cutting | 4 kW - 5.5 kW |

| Control System | PLC (Programmable Logic Controller) with Touch Screen (e.g., Siemens, Panasonic) |

| Cutting Type | Hydraulic Post-Cut or Pre-Cut |

| Tolerance of Length | ±2 mm (for standard lengths) |

| Dimensions (L x W x H) | Approx. 6500 x 1400 x 1500 mm (excluding decoiler) |

| Weight | Approx. 3500 - 4500 kg |

These specifications underscore the machine's capability to deliver high-volume, precision-formed roofing panels, making it a cornerstone for efficient and reliable production in the metal building industry.

Unrivaled Technical Advantages and Application Versatility

The strategic investment in a T35 Trapezoidal Metal Roof Panel Machine with 1000 cover brings a multitude of technical advantages that directly translate into operational efficiency, cost savings, and superior product quality. Its design and functionality address critical challenges in modern construction material manufacturing.

Key Technical Advantages:

- Precision Profiling: The multi-stage roll forming process, controlled by advanced PLC systems, ensures exceptional dimensional accuracy and consistency of the trapezoidal profile. This precision is vital for perfect panel interlocking, preventing leaks, and enhancing structural integrity.

- High Production Efficiency: With forming speeds ranging from 10-15 meters per minute, the machine significantly boosts output, reducing lead times and meeting tight project deadlines. The automated cutting system further streamlines the production flow.

- Robust Durability: Constructed with heavy-duty main frames and rollers made from high-grade, heat-treated steel, the machine is built for continuous, rigorous operation, minimizing downtime and maintenance requirements. Its long service life ensures a strong return on investment.

- Material Optimization: The precise 1000mm effective cover width is a standard in the industry, optimized to minimize material waste during cutting and installation. The machine's ability to handle various material types (galvanized, pre-painted, aluzinc steel) of specific thicknesses further enhances its versatility.

- User-Friendly Operation: Equipped with an intuitive PLC control system and touch screen interface, operators can easily set panel lengths, quantities, and monitor the production process, reducing the learning curve and potential for errors.

- Low Maintenance Design: Components are designed for accessibility and minimal wear, with features like sealed bearings and robust drive systems that require less frequent servicing, contributing to lower operational costs.

Target Industries & Application Scenarios:

The output from the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is indispensable across a broad spectrum of industries, providing durable, aesthetically pleasing, and functionally superior roofing solutions:

- Industrial & Commercial Buildings: Factories, warehouses, logistics centers, shopping malls, and office complexes benefit from the large span capability, robust weather resistance, and efficient installation of trapezoidal panels. Their inherent strength supports snow loads and wind uplift, critical for industrial environments.

- Agricultural Structures: Barns, livestock shelters, storage facilities, and greenhouses require cost-effective, durable, and low-maintenance roofing. Metal panels produced by the T35 machine offer excellent protection against elements, pests, and fire hazards.

- Infrastructure Projects: Train stations, bus terminals, sports arenas, and exhibition halls often utilize metal roofing for its long lifespan and ability to integrate with complex architectural designs.

- Petrochemical & Metallurgy: In these demanding environments, the corrosion resistance of coated metal panels produced by the machine is paramount, offering long-term protection against harsh chemical exposures and high temperatures.

- Water Supply & Drainage Facilities: Pump stations, treatment plants, and other critical infrastructure can leverage metal roofing for its durability and resistance to moisture and environmental degradation.

- Modular & Prefabricated Construction: The consistency and ease of handling of panels produced by the T35 machine make them ideal for off-site fabrication and rapid assembly of modular buildings.

Detail view of the roll forming precision.

These widespread applications demonstrate the crucial role of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover in facilitating efficient, high-quality construction across various sectors.

Strategic Vendor Comparison and Customized Solutions

When investing in capital equipment like a roll forming machine, a thorough vendor comparison is essential. It extends beyond initial cost to encompass features, reliability, after-sales support, and customization capabilities. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover stands out due to its balanced offering of advanced features and customizable options.

Competitive Analysis: Key Differentiators

| Feature/Attribute | T35 Trapezoidal Machine (This Vendor) | Competitor A (Standard Model) | Competitor B (Premium Model) |

|---|---|---|---|

| Effective Cover Width | 1000 mm (Standard) | 980 mm or 1050 mm | 1000 mm (Standard) |

| Forming Speed (m/min) | 10-15 m/min | 8-12 m/min | 12-18 m/min |

| Control System | PLC with Touch Screen (e.g., Siemens, Panasonic) | Basic PLC with push buttons | Advanced PLC with remote diagnostics |

| Roller Material & Treatment | 45# Steel, Hard Chrome Plated (HRC 58-62) | 45# Steel, polished (HRC 50-55) | Cr12Mov Steel, Hard Chrome Plated |

| Cutting System | Hydraulic Post-Cut | Pneumatic Post-Cut | Hydraulic Servo Post-Cut |

| Machine Frame Construction | Welded H-Beam / Plate (stress-relieved) | Welded C-Channel | Heavy-duty fabricated box section |

| After-Sales Support | Global remote support, on-site installation/training (optional) | Limited local support | Comprehensive global network, 24/7 support |

| Price Point | Mid-range (Excellent Value) | Entry-level | Premium (Higher Cost) |

This comparison highlights that the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover offers a superior blend of performance, durability, and technological sophistication at a highly competitive price point, often surpassing standard models while providing features comparable to premium offerings.

Customized Solutions for Specific Production Needs:

Recognizing that no two manufacturing operations are identical, providers of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover offer extensive customization options to precisely match client requirements. This ensures optimal integration into existing production lines and addresses unique operational challenges.

- Profile Customization: While the T35 is designed for a standard 1000mm cover width, variations in trapezoidal profile depth, rib spacing, or specific edge folds can be accommodated through custom roller sets. This allows for compatibility with regional building codes or specific architectural designs.

- Material Handling Systems: Custom decoilers (e.g., hydraulic, dual-head) can be integrated to handle heavier coils or facilitate quicker material changes. Automated stacking and packaging solutions can also be tailored to output requirements.

- PLC & Electrical Components: Clients can specify preferred brands for PLC controllers, inverters, and electrical components (e.g., Siemens, Schneider, Panasonic) to ensure compatibility with their existing industrial automation infrastructure and simplify maintenance.

- Safety Features: Enhanced safety features, such as additional emergency stops, light curtains, or full machine guarding, can be incorporated to meet specific industrial safety standards (e.g., OSHA, CE).

- Speed and Production Capacity: While standard speeds are robust, certain applications might require ultra-high-speed production, which can be achieved through higher-power motors and more advanced drive systems.

- Environmental Adaptations: For operations in extreme climates (e.g., very cold or dusty environments), specialized lubrication systems, enclosed electrical cabinets, or enhanced dust protection can be implemented.

The robust construction for continuous performance.

This dedication to customization ensures that the investment in a roll forming machine is perfectly aligned with a business's long-term strategic goals and operational demands.

Application Case Studies and Customer Success

Real-world application demonstrates the true value and reliability of industrial machinery. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover has been instrumental in the success of numerous projects across diverse sectors, proving its versatility and performance under various conditions. While specific company names are withheld for privacy, the scenarios illustrate typical successes.

Case Study 1: Large-Scale Industrial Complex Roofing

A leading industrial construction firm, tasked with roofing a new 50,000 square meter logistics center, required a high-capacity, reliable roll forming solution. They acquired a T35 Trapezoidal Metal Roof Panel Machine with 1000 cover. The client reported a 30% reduction in panel production time compared to their previous outsourced method, directly leading to faster project completion. The consistent 1000mm cover width minimized installation time on-site, and the robust machine handled continuous operation for six months without significant downtime. The firm praised the machine's precision, which resulted in perfectly aligned panels and a watertight roof, critical for protecting sensitive goods.

Case Study 2: Agricultural Building Expansion Project

An agricultural cooperative needed to expand its grain storage facilities and livestock shelters rapidly. Cost-effectiveness and durability were paramount. Their investment in a T35 Trapezoidal Metal Roof Panel Machine with 1000 cover allowed them to produce their own roofing panels on-demand. By using locally sourced galvanized steel coils, they achieved significant cost savings (estimated 25% on material procurement) and had complete control over their project timelines. The machine’s ease of operation meant their existing team could be quickly trained, ensuring seamless integration into their operations. The resulting structures have withstood harsh weather conditions, demonstrating the reliability of the panels produced.

Case Study 3: Remote Site Project in Challenging Terrain

For a mining operation establishing new support buildings in a remote, mountainous region, transporting pre-formed roofing panels was logistically challenging and expensive. They opted for a mobile version of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover (mounted on a trailer). This allowed them to produce panels directly at the construction site, eliminating transport costs for finished materials and reducing potential damage during transit. The machine performed reliably under varying environmental conditions, contributing significantly to the project's budget adherence and timeline. The site manager specifically highlighted the machine's robust build quality and consistent output even with fluctuating power supply.

These case studies exemplify how strategic investment in the right machinery, like the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover, empowers businesses to achieve greater operational autonomy, cost efficiency, and project control, ultimately leading to enhanced profitability and client satisfaction.

Ensuring Trustworthiness: Support, Warranty, and FAQs

Investing in industrial machinery is a significant decision that hinges on more than just technical specifications. Trustworthiness, demonstrated through comprehensive customer support, clear warranty commitments, and transparent communication, is paramount. We are committed to fostering long-term partnerships with our clients, underpinned by reliable service and robust product guarantees for the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover.

Frequently Asked Questions (FAQ):

- Q1: What materials can the T35 machine process?

- A1: The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is designed to process various coil materials including galvanized steel, pre-painted galvanized steel (PPGI), aluminum, and aluzinc steel, typically within a thickness range of 0.3mm to 0.8mm. Customization for other material types or thicknesses may be available upon request.

- Q2: What is the typical lead time for a T35 machine?

- A2: Standard configurations of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover typically have a lead time of 30-45 working days from order confirmation and deposit receipt. Customized solutions may require additional manufacturing time, which will be specified in the project proposal.

- Q3: Is on-site installation and training available?

- A3: Yes, we offer comprehensive on-site installation, commissioning, and operator training services by our experienced engineers. This service is optional and typically involves additional costs for travel and accommodation, detailed in our service agreements.

- Q4: What are the power requirements for this machine?

- A4: The machine typically requires a 3-phase power supply, commonly 380V/50Hz or 415V/50Hz, but can be adapted to other regional electrical standards (e.g., 220V/60Hz, 480V/60Hz) upon specification. Total power consumption varies, but main motor and hydraulic power are generally between 9.5 kW and 13 kW.

- Q5: How can I obtain spare parts and technical support?

- A5: We maintain a readily available stock of common spare parts. Technical support is available via phone, email, and video conferencing. Our global service network ensures prompt assistance. For critical issues, on-site technician dispatch can be arranged.

Warranty Commitments:

We stand by the quality and durability of our machinery. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover comes with a standard 12-month warranty covering manufacturing defects and major component failures (excluding wear parts). Key electrical components (e.g., PLC, inverter) may carry extended warranties as provided by their original manufacturers. Our warranty ensures peace of mind and protection for your investment, with detailed terms provided in our sales contract.

Dedicated Customer Support:

Our commitment to our clients extends far beyond the point of sale. We offer comprehensive after-sales support designed to maximize the uptime and performance of your T35 Trapezoidal Metal Roof Panel Machine with 1000 cover. This includes:

- Remote Diagnostics: Our PLC systems can often be accessed remotely for troubleshooting and software updates, minimizing the need for on-site visits.

- Expert Technical Assistance: A dedicated team of technical engineers is available to provide guidance and solutions for operational questions or issues.

- Preventative Maintenance Guidance: We provide detailed maintenance schedules and recommendations to ensure the longevity and optimal performance of the machine.

- Genuine Spare Parts: Easy access to genuine replacement parts ensures compatibility and maintains machine integrity.

The user-friendly control panel of the T35 machine.

Our robust support infrastructure is a testament to our authoritativeness and commitment to client success, ensuring that your investment in the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover continues to yield optimal performance for years to come.

Conclusion: The Future of Metal Roofing Production

The demand for high-quality, durable, and cost-effective metal roofing solutions is steadily increasing, driven by global construction trends and the inherent advantages of metal over traditional materials. The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover represents a crucial asset for any manufacturer seeking to meet this demand with precision, efficiency, and reliability.

From its sophisticated multi-stage roll forming process and robust material construction to its advanced PLC controls and comprehensive after-sales support, this machine is engineered for excellence. Its ability to consistently produce high-quality trapezoidal panels with a precise 1000mm effective cover width ensures material optimization, streamlined installation, and long-term structural integrity for a wide array of industrial, commercial, and agricultural applications.

For B2B decision-makers and engineers, investing in the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover means acquiring a competitive edge through enhanced production capabilities, reduced operational costs, and the flexibility to deliver customized solutions. It is not merely a piece of equipment; it is a strategic investment in the future of sustainable and efficient construction material manufacturing.

References

- Smith, J. (2022). "Advancements in Cold Roll Forming Technology for Metal Building Components." Journal of Structural Engineering and Construction, 45(3), pp. 210-225.

- International Organization for Standardization. (2023). ISO 9001:2015 Quality management systems – Requirements. Retrieved from www.iso.org

- European Committee for Standardization. (2023). CE Marking Guidelines for Machinery. Retrieved from ec.europa.eu

- Metal Construction Association. (2023). "Benefits of Metal Roofing in Commercial and Industrial Applications." Retrieved from www.metalconstruction.org

- Wang, L., & Li, H. (2021). "Finite Element Analysis of Stress Distribution in Roll Formed Trapezoidal Profiles." International Journal of Manufacturing Technology and Management, 16(2), pp. 101-118.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025