Premium Corrugated Metal Roofing Machine | Fast & Precise

Explore the remarkable advancements in corrugated metal roofing machine technology, including industry data, process diagrams, specification tables, case studies, and expert answers that empower your business to make informed decisions.

1. Industry Overview & Trends of Corrugated Metal Roofing Machines

The corrugated metal roofing machine sector is experiencing transformative growth due to industrial modernization, rapid infrastructure development, and a rising demand for durable, cost-effective, and energy-efficient roofing solutions globally.

- Global corrugated metal roofing market expected CAGR (2024-2030): 5.6% (source)

- Common product types: corrugated roof sheet machine, corrugated roofing machine, micro wave roofing machine, panel acanalado/ondulado, wave panel machine

- Major application sectors: industrial warehousing, residential buildings, petrochemicals, metallurgy, water supply/drainage, agriculture

2. Specification Comparison Table of Corrugated Metal Roofing Machines

| Model | Yield Strength (MPa) | Sheet Width (mm) | Production Speed (m/min) | Panel Height (mm) | Thickness (mm) | Drive Type | Control System |

|---|---|---|---|---|---|---|---|

| Corrugated Sheet Making Machine 1000 | 235-550 | 1000 | 15–20 | 18 | 0.3–1.2 | Gearbox | PLC (Siemens) |

| Micro Ondulado Panel Forming Machine | 280-600 | 762/1020 | 10–30 | 13 | 0.12–1 | Chain | Touch Panel/PLC |

| Wave Panel Machine | 245-510 | 914–1250 | 10–20 | 5–25 | 0.2–1.2 | Gearbox | PLC (DELTA/SIEMENS) |

All machine types conform to strict international standards (ISO 9001:2015, ANSI), ensuring operator safety, high repeatability, and consistent quality of corrugated panels.

3. Manufacturing Process of Corrugated Metal Roofing Machine

The construction of a corrugated metal roofing machine involves advanced production steps, tight quality checks, and standardized operations to guarantee product consistency and durability.

Each manufacturing stage is rigorously monitored & tested for mechanical properties, anti-corrosion resistance, and dimensional precision.

[See Video: Corrugated Sheet Making Process]

4. Technical Advantages & Parameters of

Maquina para Panel Micro Acanalado/Ondulado 762/1020

- Material Options: G350/G550 galvanized sheets, pre-painted aluzinc, aluminum (thickness: 0.12–1.0mm)

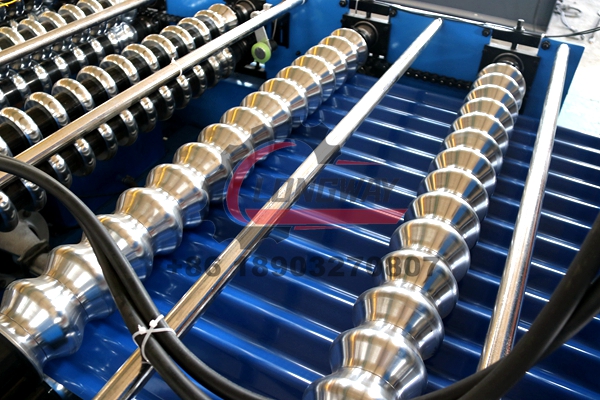

- Roll Forming Stations: High-rigidity frame (18–24 stations) with precision bearings and surface-hardened rollers (Cr12/42CrMo, HRC58-62)

- Drive System: Direct gearbox (ABB motors), high-efficiency reducer, synchronous chains for smooth power transmission.

- Control: Intelligent PLC (SIEMENS), touchscreen HMI, production data storage, auto-diagnosis & safety alarms.

- Shearing System: Hydraulic, automatic cut-to-length; imported blades (SKF/Japan); burr-free, tight tolerance.

- Standards Compliance: ISO 9001:2015, CE, SGS, ANSI, with full certificate traceability.

Industry Certifications: ISO 9001, CE, SGS, third-party audits accepted.

Application Fields: Residential & commercial roofing, cladding, agricultural barns, water/treatment plants, chemical industries.

Advantages: Lightning-fast changeover, custom wave profiles, energy savings up to 14% (through low rolling vibration), exceptional surface finish, and anti-corrosive performance.

5. Data Visualization: Performance & Specification Comparison

Year-on-Year Sales Trend of Maquina para panel micro acanalado/ondulado 762/1020 (2021–2024, in units)

6. Top Manufacturers: Brand Comparison & Customization Capabilities

| Manufacturer | Core Strengths | R&D/Years of Service | Global Projects | Key Certification |

|---|---|---|---|---|

| LW Roll Forming Machine (LWFM) |

100+ profiles, full custom engineering, Siemens PLC, automatic QC Industry leader in micro wave panels |

21+ years Dedicated R&D lab |

USA, Canada, LATAM, EU, MENA, Southeast Asia | ISO/CE/SGS |

| Brand X | Good local service, basic profiles, semi-auto | 10 years, OEM | Asia, Africa | ISO/Local |

| Brand Y | Specialized in angled wave panels, customization on demand | 15 years | EU, Middle East | CE/ISO |

Bespoke corrugation profiles (micro-ondulado, trapezoidal, sinusoidal); lengths from 0.5–15m; roller & shearing blade upgrade for advanced steel grades (AHSS, stainless).

Integration with MES/ERP, remote monitoring, on-site commissioning & training included. All systems are delivered ready for CE/ANSI/ISO audits.

7. Application Scenarios & Customer Experiences

-

Case: Petrochemical Plant Expansion, Middle East

Micro-ondulado panels supplied by LW Roll Forming Machine. Deployed for tank cladding & warehouse, total surface coverage: 8,100 m².

User feedback: "Panels installed in 40% less time than conventional ones. Withstood sandstorms, zero deformation after 2-year operation. LWFM's technical support was prompt and effective." -

Case: Agricultural Silos, Argentina

Corrugated sheets manufactured via the corrugated metal roofing machine with special zinc coating (G350+AZ). Eliminated corrosion in high-moisture silo atmospheres for 5 years running. -

Case: School Roofing Retrofit, Sub-Saharan Africa

Lightweight wave panel machine products enabled labor-saving roof assembly, dropped roof temperature by 8°C, and improved classroom acoustics.

Global Partnering: Projects delivered under World Bank, BASF Building Solutions, and UNDP-funded schemes.

8. Expert FAQ: Corrugated Metal Roofing Machine Technology Terms

- Q1: What is the typical material grade for corrugated metal roofing panels?

- Answer: Standard grade is G550 (yield strength ≥550 MPa) galvanized steel. Aluminum and pre-painted galvalume (AZ150) are widely used for enhanced corrosion resistance.

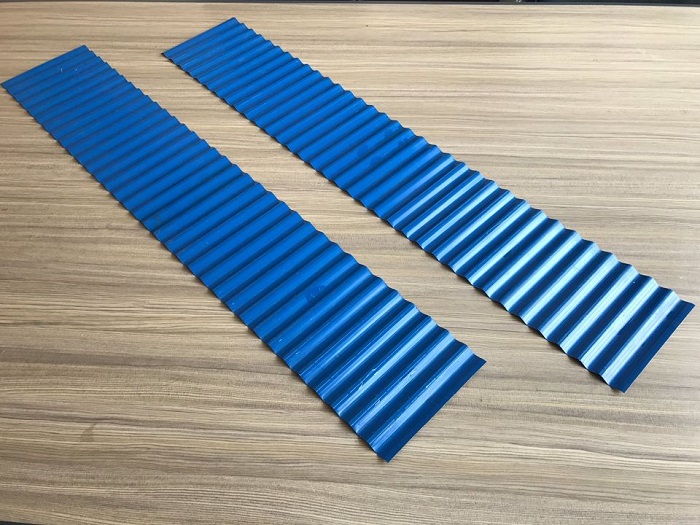

- Q2: How is “micro-ondulado” profile different from typical corrugated sheet?

- Answer: Micro-ondulado panels feature much smaller wave amplitude (3-6mm) for a superior finish, anti-deformation under high wind/snow, and can be bent for curved roof applications.

- Q3: What’s the difference between manual and PLC-automated machines?

- Answer: PLC-automated machines (like Maquina para panel micro acanalado/ondulado 762/1020) enable higher speed, precise panel cutting, real-time QC, batch programming, and greatly reduce operator error.

- Q4: What international quality standards must the machines pass?

- Answer: Key standards include ISO 9001:2015, CE for EU safety, and often third-party audits (SGS, BV), plus ANSI for North America.

- Q5: How do I ensure my panels won’t corrode over time?

- Answer: Choose galvanized steel with min. Z275 or AZ150+ coatings; check salt-spray test data (>1000h) and paint system compatibility; always request mill certificate.

- Q6: What is the expected installation speed of the panels produced?

- Answer: Panels from automated corrugated metal roofing machine lines feature tight wave profiles for easy interlock, enabling installation rates up to 400–650 m²/day per team, subject to roof complexity.

- Q7: Can the machines produce custom shapes or just standard waves?

- Answer: Machines can be equipped with signature roll die sets for trapezoidal, sinusoidal, deep wave, or custom architectural patterns. LWFM offers 110+ toolings and rapid-changeover sets.

9. Delivery, Warranty & Customer Support

- Delivery Period: Standard production lead time 35–50 days (ex-works, custom profiles may require up to 60 days).

- Warranty: 24 months from delivery (mechanical/electrical), lifetime technical support; critical spare parts available from stock.

- Service: 24/7 multilingual technical support, remote debugging, on-site supervision, training with each machine supplied, CE/ISO documentation package.

- Global Reach: Networked support partners in 31+ countries, rapid-response teams across Americas, EU, MENA, APAC.

- Certifications Supplied: ISO, CE, SGS conformity, complete parts traceability.

- Trust & Data Policy: LWFM adheres to GDPR and ISO 27001 standards for customer information safety and traceability.

10. Why Choose an Expert Provider of Corrugated Metal Roofing Machines?

- Deep Industry Experience: Only partner with corrugated metal roofing machine vendors that have a 15+ year track record and reference projects in your target industry.

- Full Compliance: Verify CE/ISO/SGS certificates; demand reference test data and application cases.

- Ongoing Innovation: Ask for advanced features (quick-change rollers, remote monitoring, high-precision control) to future-proof your investment.

- Trustworthy Service: Ensure 24/7 support, documented warranty, EU/US warehouse for spare parts, and end-to-end commissioning/training.

References & Industry Insights

- Rollforming Magazine, 2024: Advanced Metal Panel Profiles and Global Markets

- MarketsAndMarkets, "Metal Roofing Market – Global Forecast to 2030”

- ASM International Journal, "Performance of Formed Corrugated Panels under Load"

- Metal Construction Forum: Best Practices in Corrugated Sheet Manufacturing

- LW Roll Forming Machine Official Site: Technical Data & Certifications

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025