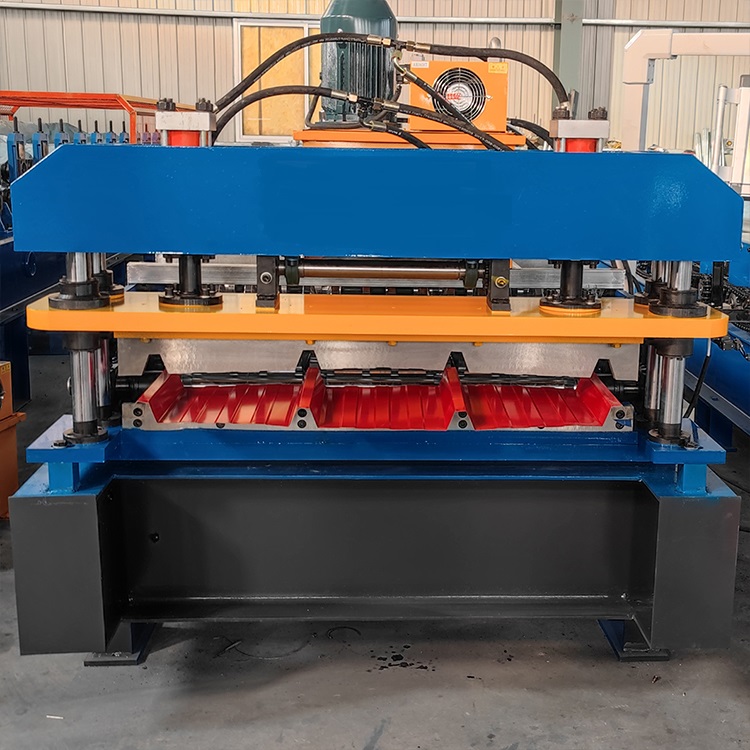

TR4 Metal Roofing Panel Roll Forming Machine for sale | PLC

TR4 roofing panels are having a moment — here’s the machine behind the trend

If you’re scouting for capacity, consistency, and low scrap on Latin-style trapezoid panels, the TR4 Metal Roofing Panel Roll Forming Machine for sale is the model I keep hearing about on shop floors. Built in SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE, it’s been landing strong orders in Peru (no surprise — TR4 is a local favorite) and quietly popping up across warehouse and market-roof projects. To be honest, what stands out is not just the profile quality but the easy add-on roof-curving unit for those gentle radius sheds.

What’s driving the TR4 wave

Two macro trends: steel price volatility (you can’t waste coils) and faster site turnarounds. Contractors want panels on demand, with tight fit-up, less sealing drama. The TR4 Metal Roofing Panel Roll Forming Machine for sale answers that with steady line speed, ±0.5 mm typical width accuracy, and cut-to-length consistency that keeps installers happy. Plus, that curving option means fewer lap joints on arch roofs — big deal in rainy season.

Core specs (shop-floor reality)

| Profile | TR4 trapezoid (Peru-popular), roof curving attachment optional |

| Material | Galvanized (ASTM A653), Galvalume (ASTM A792), Pre-painted (PE/SMP/PVDF) |

| Thickness range | ≈0.30–0.70 mm (real-world use may vary by yield strength) |

| Coil width | 914–1220 mm |

| Forming speed | 12–18 m/min typical; up to ≈20 m/min with light gauges |

| Stations / shafts | 16–20 stations, shafts ≈70 mm |

| Rollers | 45# steel or GCr15, quenched, hard-chrome |

| Drive & cut | Chain/gearbox drive; hydraulic post-cut, die steel Cr12MoV |

| Power & control | Main 5.5–7.5 kW; hydraulic 4 kW; PLC Siemens; HMI touch |

| Tolerance | Width/length ±0.5 mm at 15 m/min (factory FAT data) |

Process flow, testing, and service life

- Decoiling → Pinch/feed → Leveling → Roll forming → Hydraulic post-cut → Output rack; optional curving (radius as required).

- Methods: CAD/CAM roll design, finite-element pass optimization, profile verification with go/no-go gauges.

- Testing: Coating thickness per ISO 2808; salt spray to ASTM B117 (1,000 h typical on PVDF panels); electrical safety per IEC 60204-1; CE marking available.

- Service life: Rollers ≈5–8 years; hydraulic seals 2–3 years; line frame 10–15 years with routine lubrication and chain tension checks.

- Industries: Warehouses, markets, logistics hubs, agro sheds, coastal resorts (with AZ coatings), community projects.

How it compares (honestly)

| Criteria | LW TR4 | Generic import | Used line |

|---|---|---|---|

| Panel accuracy | ±0.5 mm | ±0.8–1.5 mm | Varies |

| Curving option | Factory-matched | Sometimes | Rare |

| Lead time | 30–45 days | 45–75 days | Immediate |

| Warranty | 12–18 months | 6–12 months | None |

| Spare parts | Stocked | Mixed | Sourcing required |

Customization that actually matters

Most buyers tweak coil width, rib height, embossing, and the curving radius. Electricals can be 380 V/50 Hz or 440 V/60 Hz. I’ve seen shops ask for gearbox drive, auto-stacker, and offline punching. The TR4 Metal Roofing Panel Roll Forming Machine for sale handles those without drama.

Field notes and mini case

Lima, 2023: a mid-size fabricator swapped to this line, ran 0.45 mm AZ panels at ≈16 m/min. Their installer told me, “we cut sealant by half.” Factory FAT logged length tolerance at ±0.3 mm and sound level under 78 dB. Another customer said scrap dropped ≈15% versus their old chain-only unit — small tweaks in roller geometry do add up.

Compliance and documentation

Supplier provides CE, ISO 9001 QA traceability, materials MTCs, and an English wiring diagram. For coastal projects, they recommend AZ150 with PVDF; for agro sheds, SMP often hits the cost/survivability sweet spot.

Bottom line? If your mix is Peru-style TR4 with occasional curved roofs, the TR4 Metal Roofing Panel Roll Forming Machine for sale is a pragmatic pick: steady output, sensible accuracy, and support that—surprisingly—answers on WeChat after hours.

Authoritative references

- ISO 9001:2015 Quality Management Systems.

- ASTM A653/A653M & ASTM A792/A792M for coated steel sheet.

- ISO 2808 Paints and varnishes — Determination of film thickness.

- ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus.

- IEC 60204-1 Safety of machinery — Electrical equipment of machines.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025