Corrugated Metal Roofing Machine | High-Speed Precision

Aluzinc PV4 y Calamina: a field note on the Corrugated Metal Roofing Machine you actually want to run

If you work in roofing fabrication, you know the story: inconsistent profiles, scrap headaches, and buyers who need sheets yesterday. The Aluzinc PV4 y Calamina roofing sheet making machine from SHIBAWUXING Village, Bo Town, Cangzhou City, Hebei Province hits a practical sweet spot—fast deployment (PV4 y Calamina, ~40 days delivery), solid tolerances, and, to be honest, fewer fussy adjustments than some imports I’ve tested.

Industry pulse

Demand for galvanized/galvalume corrugated sheets is still rising in Latin America, Southeast Asia, and parts of Africa—driven by modular builds and post-storm replacements. Profiles like PV4 (sometimes called “Calamina” regionally) remain a staple. Many customers say they’re swapping to Aluzinc (AZ) coils for better corrosion resistance, especially near coasts. Makes sense.

Key specs (real-world, not brochure fluff)

| Model | Aluzinc PV4 y Calamina roofing sheet making machine |

| Base metal | GI/GL/Aluzinc (ASTM A792 / JIS G3321), typical AZ150; thickness 0.18–0.8 mm |

| Coil width | ≈ 914–1250 mm (profile-dependent) |

| Yield strength | 235–550 MPa (G300–G550) |

| Line speed | 12–18 m/min; real-world after cut ≈ 10–15 m/min |

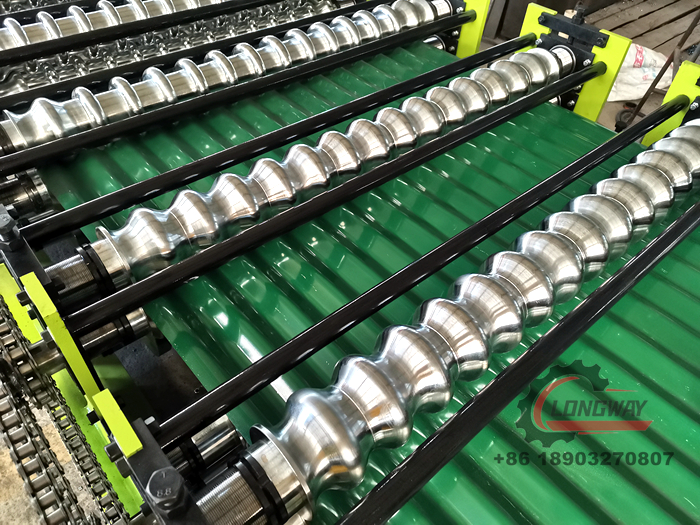

| Stations / Drive | 16–22 stations; chain or gearbox drive; shafts ≈ Φ70 mm |

| Cutting | Hydraulic, Cr12MoV blades, burr-minimized |

| Control | PLC + HMI (Siemens/Delta), encoder length control, tolerance ≈ ±1.0 mm |

| Lead time | Around 40 days delivery |

Process flow, testing, service life

- Materials: GI/GL/Aluzinc coils meeting ASTM A792 / JIS G3321; optional color coating (PE/SMP/PVDF).

- Methods: Decoiler → leveling → roll forming (heat-treated rollers) → hydraulic cutting → auto stacker.

- Testing standards: coating mass per ASTM A792; profile check vs CAD; burr and bow control per internal QA (ISO 9001 framework).

- Service life: sheets ≈ 25–40 years (site-dependent); machine frame and rollers designed for multi-year continuous duty with routine lubrication.

- Industries: residential roofing, agro sheds, logistics warehouses, temporary housing, coastal projects (with AZ150+).

Why this Corrugated Metal Roofing Machine gets picked

Stable profile integrity on thin gauges (0.2–0.3 mm) and quick switchover are the real wins. Actually, it’s surprisingly forgiving on mixed coil lots. A contractor in Lima told me their scrap rate dropped below 2% after dialing in the encoder and pre-cutter timing.

Vendor snapshot (informal comparison)

| Vendor | Lead time | Control | Certs | Notes |

|---|---|---|---|---|

| LW Roll Forming (Cangzhou, Hebei) | ≈ 40 days | PLC + encoder | ISO 9001, CE (model-dependent) | PV4/Calamina ready; good after-sales |

| Local fab shop | 8–12 weeks | Basic relay/PLC | Varies | Easy onsite support; mixed tolerances |

| EU importer brand | 10–16 weeks | PLC + servo | CE, ISO | Higher price; premium enclosures |

Customization and quick cases

- Customization: gearbox drive upgrade, crimping add-on, PV4 depth tweaks, 5T–10T hydraulic decoiler, servo length control, logo embossing.

- Peru (PV4/Calamina): 0.25 mm AZ roof sheets for hillside housing; reported uptime 95% after 3 months.

- Philippines (coastal): AZ150, PVDF topcoat; line speed capped at 12 m/min to protect paint, still met delivery windows.

Corrugated Metal Roofing Machine buyers keep asking about compliance and data. Fair point. Coils should comply with ASTM A792 or JIS G3321; factories often operate under ISO 9001. I’ve seen in-house tests: coating mass verification, hardness checks, and 10-piece sample length audits (±1.0 mm typical) before sign-off. Real-world use may vary—humidity, fasteners, and site practices matter.

Origin: SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE.

Authoritative references

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025