High-Precision Metal Sheet Perforated Machine for Efficient Punching

Elevating Precision Manufacturing with Advanced Metal Sheet Perforation Technology

In the realm of modern industrial fabrication, the demand for precise, durable, and aesthetically versatile perforated metal components is continually expanding. This growth underscores the critical role of sophisticated machinery in achieving high-quality output efficiently. At the forefront of this technological advancement is the metal sheet perforated machine, a cornerstone technology enabling the creation of intricate patterns and functional designs across a spectrum of materials. This article delves into the intricacies of this essential equipment, exploring its operational mechanics, diverse applications, and the competitive advantages it offers in today's dynamic manufacturing landscape.

Industry Trends Driving Perforation Technology

The market for perforated metal products is experiencing robust growth, driven by key trends such as the increasing adoption of lightweight materials in automotive and aerospace, the surge in sustainable architectural designs requiring improved ventilation and light diffusion, and the ever-present need for advanced filtration and acoustic solutions. Recent market analyses project the global perforated metal market to reach USD 3.5 billion by 2028, with a compound annual growth rate (CAGR) of over 4.5% from 2023. This trajectory demands continuous innovation in metal sheet punching technologies, focusing on higher precision, increased automation, and greater material versatility. Manufacturers are seeking solutions that not only enhance production speed but also reduce material waste and operational costs, pushing the boundaries of traditional punching machine capabilities. The integration of IoT and AI in modern metal sheet perforated machine systems is becoming a significant trend, enabling predictive maintenance, real-time quality control, and optimized production schedules.

The Manufacturing Process Flow of a Metal Sheet Perforated Machine

The production of a high-quality metal sheet perforated machine is a multi-stage process, meticulously designed to ensure durability, precision, and long-term operational efficiency. Adherence to stringent manufacturing processes and quality control standards is paramount.

Schematic Steps:

- Material Selection & Sourcing: High-grade steel alloys (e.g., Q235B, Q345B for structural components, CrMoV for dies) are selected based on their mechanical properties, fatigue resistance, and machinability. Certification to ISO 630 standards ensures material quality.

-

Component Manufacturing (Casting & Forging):

- Casting: Large structural elements like the machine frame and bolster are typically cast from high-strength ductile iron or steel, followed by stress relief annealing to enhance stability and reduce internal stresses.

- Forging: Critical components such as crankshafts, connecting rods, and gear blanks are forged for superior grain structure, resulting in higher strength and impact resistance.

- Precision CNC Machining: Post-casting or forging, components undergo advanced CNC machining processes (milling, turning, grinding) to achieve micron-level tolerances for critical interfaces and moving parts. This ensures smooth operation and extended service life.

- Heat Treatment: Dies, punches, and wear-critical parts receive specialized heat treatments (e.g., hardening, tempering, nitriding) to achieve optimal hardness, wear resistance, and toughness, critical for efficient metal sheet punching.

- Assembly & Integration: Skilled technicians meticulously assemble mechanical, hydraulic, and electrical systems. This includes precise alignment of the punching head, feeding mechanisms, and control units.

- Calibration & Testing: Each machine undergoes rigorous testing protocols, including dry cycle tests, load tests, and precision tests against ISO 9001 and ANSI B11.1 standards. Parameters like punching force accuracy, stroke speed, and positional repeatability are validated. Energy consumption is measured to demonstrate energy-saving capabilities.

- Quality Control & Final Inspection: A final comprehensive inspection ensures all specifications are met and the machine is ready for dispatch, often including a test run with customer-specified materials to confirm performance.

The typical service life of a well-maintained metal sheet perforated machine ranges from 15 to 25 years, depending on operational intensity and adherence to maintenance schedules. Target industries include petrochemical (for filters, gratings), metallurgy (screens, protective covers), water supply & drainage (filtration screens, diffusers), and architectural sectors. Advantages manifest in scenarios requiring high corrosion resistance through material choice (e.g., stainless steel punching for marine environments) and significant energy savings through optimized servo-hydraulic systems compared to traditional mechanical presses.

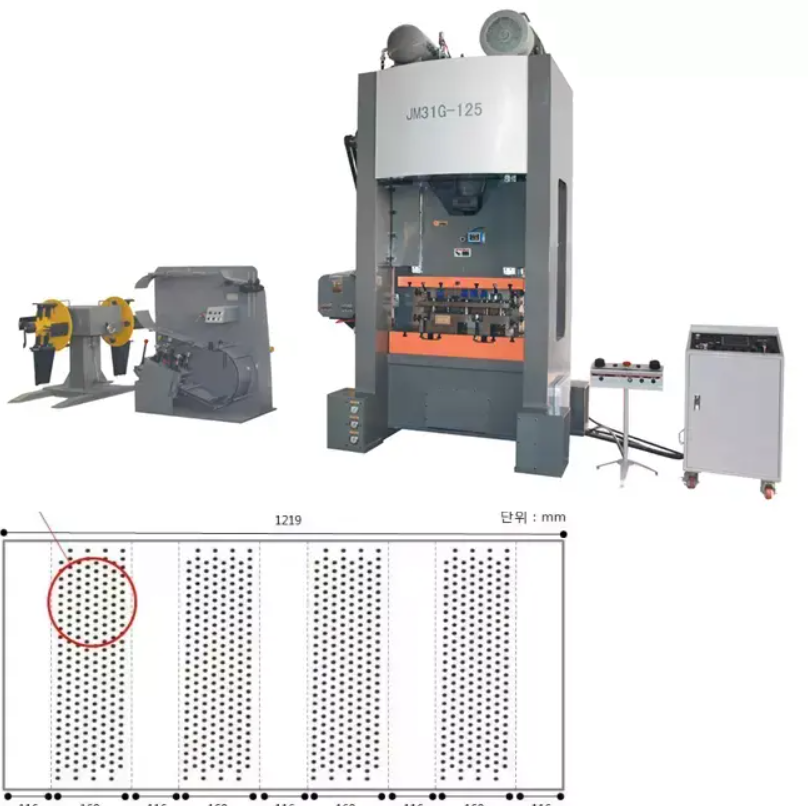

Fig 1. Detailed component manufacturing for a Metal Sheet Perforated Machine.

Technical Specifications of an Advanced Metal Sheet Perforated Machine

Understanding the core technical parameters is crucial for selecting the right punching machine for specific industrial requirements. Modern machines offer a blend of power, precision, and versatility to handle diverse materials and applications. The following table outlines typical specifications for a high-performance sheet metal punching line.

| Parameter | Specification | Description / Note |

|---|---|---|

| Max. Punching Force | 250 kN - 800 kN | Varies by model; impacts maximum material thickness. |

| Max. Sheet Thickness (Mild Steel) | 0.5 mm - 6.0 mm | Dependent on material tensile strength and punch diameter. |

| Max. Sheet Size (X x Y) | 1250 x 2500 mm (standard) up to 1500 x 4000 mm (extended) | With or without repositioning capabilities. |

| Punching Speed (Strokes/min) | 600 - 1500 SPM (hits/min) | High-speed punching for efficient production; varies with hole spacing. |

| Tool Stations | 20 - 60 stations (turret) or up to 200 (linear magazine) | Supports diverse tooling for various hole shapes and sizes. |

| Material Types | Mild steel, Stainless steel, Aluminum, Copper, Brass, Galvanized steel | Requires appropriate tooling and machine settings. |

| Control System | Siemens / Fanuc / Mitsubishi CNC | Advanced control for precision and automation. |

| Repositioning Accuracy | ±0.05 mm | Critical for complex patterns and large sheets. |

| Connectivity | Ethernet, USB, Optional Remote Monitoring | Enables integration into smart factory environments. |

Fig 2. Advanced Metal Sheet Perforated Machine in operation.

Diverse Application Scenarios

The versatility of the metal sheet punching process means perforated metals are ubiquitous across numerous industries. From functional components to decorative elements, their applications are vast and varied.

- HVAC Systems: Used in air diffusers, grilles, and filters to control airflow and provide aesthetic finishes. The uniform perforations ensure consistent air distribution.

- Architectural and Construction: Façade cladding, sunscreens, balustrades, ceilings, and infill panels benefit from perforated metal for aesthetic appeal, light diffusion, and ventilation. They offer privacy while maintaining an open feel.

- Automotive Industry: Components such as radiator grilles, oil filters, and exhaust system parts require precise perforation for optimal performance and heat dissipation. A metal sheet punching production line can handle high-volume demands for these applications.

- Filtration and Separation: Essential for screens in water treatment plants, industrial filters, strainers, and centrifuges, providing precise particle separation.

- Acoustics: Sound-absorbing panels in recording studios, auditoriums, and office spaces utilize perforated metal to manage sound reverberation effectively.

- Food and Beverage: Used in drying trays, sieves, and sorting equipment where hygiene and precise separation are critical.

- Agriculture: Grain silos, sorting screens, and ventilation panels require durable perforated sheets.

Technical Advantages and Operational Efficiency

The deployment of an advanced metal sheet perforated machine brings a multitude of technical and operational advantages to manufacturers, significantly impacting productivity, quality, and cost-effectiveness.

- High Precision & Repeatability: Modern CNC-controlled punching machines offer exceptional positional accuracy (typically ±0.05 mm) and shot-to-shot repeatability, ensuring consistent quality even across large production batches. This is critical for parts that require tight tolerances for assembly or functionality.

- Speed & Productivity: With punching speeds reaching up to 1500 strokes per minute, a sheet metal punching line can process vast quantities of material quickly. Automated sheet loading/unloading systems and intelligent nesting software further optimize throughput and minimize idle time.

- Material Versatility: Capable of processing a wide array of materials, including various grades of steel, aluminum, copper, and brass, in thicknesses ranging from thin foils to robust plates.

- Reduced Material Waste: Advanced nesting algorithms minimize scrap by optimizing the layout of punched parts on the raw sheet, leading to significant material cost savings.

- Tooling Flexibility: Quick-change tooling systems and large turret capacities allow for rapid setup changes and the ability to produce complex patterns with diverse hole shapes (round, square, slotted, embossed) without manual intervention.

- Enhanced Safety: Fully enclosed work areas, interlocked safety guards, and integrated light curtains ensure operator safety, complying with international safety standards like EN ISO 13849-1.

- Energy Efficiency: Servo-electric or servo-hydraulic drive systems found in contemporary punching machines consume significantly less power than older hydraulic or mechanical presses, contributing to lower operational costs and a reduced carbon footprint.

Fig 3. Precision punching operation with a Metal Sheet Perforated Machine.

Vendor Comparison: Choosing the Right Metal Sheet Perforated Machine

Selecting a steel plate punching machine involves evaluating various vendors based on technological prowess, after-sales support, and customization capabilities. Key differentiating factors include the machine's drive system, control interface, and the robustness of its frame.

| Feature | Vendor A (e.g., LW Roll Forming Machine) | Vendor B (Competitor) |

|---|---|---|

| Drive System | Servo-Hydraulic for optimal power & efficiency | Mechanical (less flexible, higher maintenance) |

| Control Interface | User-friendly HMI with Siemens/Fanuc CNC, remote diagnostics | Proprietary basic controller, limited connectivity |

| Automation & Feeding | Integrated auto-loading/unloading, robotic integration options | Manual loading, semi-automatic options |

| Tooling System | Thick Turret/Multi-tool system with quick-change features | Standard tool holders, longer changeover times |

| Service & Support | Global service network, 24/7 technical support, extensive spare parts inventory, 2-year warranty | Regional support, limited spare parts availability, 1-year warranty |

| Certifications | CE, ISO 9001, FDA-compliant material options | Basic CE, no ISO certification specified |

Vendors like LW Roll Forming Machine prioritize robust construction, integrating high-performance components and advanced software for superior output and reliability. Our commitment to innovation and customer support provides a significant edge in the competitive landscape.

Customized Solutions for Unique Requirements

Recognizing that every industrial application has unique demands, manufacturers of metal sheet perforated machine systems increasingly offer tailored solutions. Customization extends beyond standard configurations to address specific material, production volume, and integration needs.

- Specialized Tooling: Development of custom punches and dies for unique hole patterns, embossing, or forming operations that cannot be achieved with standard tools.

- Integrated Material Handling: Designing bespoke automated loading/unloading systems, conveyor belts, or robotic interfaces to seamlessly integrate the punching machine into an existing production line.

- Software Adaptation: Customizing the CNC software or HMI (Human Machine Interface) to meet specific operational workflows, data reporting requirements, or integrate with enterprise resource planning (ERP) systems.

- Machine Dimensions & Capacity: Adjusting the machine's footprint, punching force, or sheet size capacity to accommodate oversized materials or limited factory space.

- Environmental Adaptations: Custom solutions for extreme operating conditions, such as enhanced cooling for high-temperature environments or specialized dust extraction systems for abrasive materials.

Our engineering team collaborates closely with clients to analyze their specific challenges and design a punching machine solution that maximizes efficiency, minimizes waste, and ensures compliance with all relevant industry standards.

Application Case Studies

Real-world applications demonstrate the transformative impact of advanced metal sheet perforation technology.

Case Study 1: Enhanced Productivity for Automotive Filtration

A leading automotive supplier, specializing in oil and air filters, faced bottlenecks due to their aging punching equipment. They upgraded to an advanced metal sheet perforated machine with a servo-hydraulic drive and automated coil feeding system. The new line increased production speed by 40% and reduced material waste by 8% through optimized nesting algorithms. The precision of the new machine also led to a 15% reduction in post-processing rejection rates, significantly improving overall operational efficiency and product quality.

Case Study 2: Architectural Façade for a Green Building Project

An architectural firm required custom perforated aluminum panels for a large-scale "green" building project, designed to maximize natural light and ventilation while providing sun shading. The intricate, non-repeating patterns demanded high precision and flexibility. Utilizing a specialized punching machine with advanced CAD/CAM integration, our client was able to produce 2,000 unique panels with varying perforation densities and sizes within tight deadlines. The machine's capability to handle large sheets and complex geometries ensured the project's aesthetic and functional requirements were met with exceptional accuracy.

Case Study 3: Corrosion-Resistant Screens for Wastewater Treatment

A municipal wastewater treatment plant needed durable, corrosion-resistant screens for its primary filtration stage. Conventional machines struggled with the chosen high-grade stainless steel (316L) due to its toughness. By deploying a robust steel plate punching machine with enhanced punching force and specialized tooling, the plant achieved consistent, burr-free perforations. This resulted in screens with a significantly longer service life (projected 20% increase) and reduced maintenance downtime, critical for continuous operation in corrosive environments.

Fig 4. Example of a Metal Sheet Perforated Machine in industrial setup.

Authoritativeness and Trustworthiness: Our Commitment to Excellence

As a leading provider in the metal forming industry, LW Roll Forming Machine adheres to the highest standards of quality, reliability, and customer satisfaction. Our products, including the metal sheet perforated machine, are backed by stringent certifications and a proven track record.

- Certifications: All our equipment is CE certified, ensuring compliance with European safety, health, and environmental protection requirements. Our manufacturing processes are ISO 9001 certified, reflecting our commitment to quality management systems.

- Industry Expertise: With over 20 years of experience in designing, manufacturing, and deploying metal processing machinery, we bring unparalleled expertise to every project. Our engineering team comprises specialists in mechanical, electrical, and automation fields.

- Partner Clients: We proudly serve a global client base, including Fortune 500 companies and specialized manufacturers across North America, Europe, Asia, and the Middle East, a testament to our product quality and service reliability.

- Quality Assurance: Every machine undergoes comprehensive factory acceptance tests (FAT) and rigorous performance benchmarks to ensure it meets or exceeds published specifications and client expectations.

Frequently Asked Questions (FAQ)

Q1: What materials can your metal sheet perforated machine process?

A1: Our machines are designed to process a wide range of materials, including mild steel, stainless steel, aluminum, copper, brass, and galvanized steel, with varying thicknesses depending on the specific model and tooling configuration.

Q2: What is the typical lead time for a new machine?

A2: Standard machine configurations typically have a lead time of 8-12 weeks from order confirmation to shipment. Custom-built machines or those requiring extensive integration may require 14-20 weeks, depending on complexity.

Q3: What kind of warranty and after-sales support do you offer?

A3: We provide a comprehensive 2-year warranty on all mechanical and electrical components. Our after-sales support includes remote technical assistance, on-site troubleshooting, spare parts supply, and operator training programs, available globally.

Q4: Can your machines integrate with existing automation systems?

A4: Yes, our advanced CNC control systems are designed for seamless integration with various factory automation systems, including robotic loading/unloading, conveyor systems, and MES/ERP platforms, using standard communication protocols.

Lead Time and Fulfillment

Our streamlined production process ensures efficient order fulfillment. Standard machines are typically delivered within 8-12 weeks, while customized solutions are delivered within 14-20 weeks, including design, manufacturing, and comprehensive testing phases. We offer complete logistics support for global shipping.

Warranty Commitments

We stand by the quality of our metal sheet perforated machine systems with a standard 2-year warranty covering defects in materials and workmanship. Extended warranty options and service contracts are also available to provide long-term peace of mind.

Customer Support Information

Our dedicated customer support team is available 24/7 for technical assistance, spare parts orders, and service scheduling. We provide comprehensive training for your operators and maintenance staff to ensure optimal performance and longevity of your equipment.

Conclusion

The advanced metal sheet perforated machine stands as a testament to precision engineering and manufacturing innovation. Its ability to deliver high-quality, versatile, and efficient punching solutions makes it an indispensable asset across a multitude of industries. With continuous advancements in automation, control systems, and material handling, these machines are not just tools but strategic investments that empower businesses to achieve higher productivity, superior product quality, and sustainable operational growth.

References

- Grand View Research. (2023). Perforated Metal Market Size, Share & Trends Analysis Report.

- ISO 9001:2015 - Quality management systems. (2015). International Organization for Standardization.

- ANSI B11.1 - Safety Requirements for Mechanical Power Presses. (2019). American National Standards Institute.

- SME Manufacturing Handbook. (2018). Volume 1: Manufacturing Processes. Society of Manufacturing Engineers.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025